Rapid ThermoPRO - In-House Recycling System

Rapid ThermoPRO is the optimal solution for in-house recycling in the thermoforming industry.

- Simplicity – ThermoPRO is coming with Rapid’s unique “Open-Hearted” design as standard that drastically simplifies cleaning, service and preventive maintenance. Direct access to the heart of the machine in less than a minute!

- Extra heavy duty – The new heavy duty roller feed is designed to compress and feed cups up to 200 mm height, eliminating all manual handling at e.g. startups. – Grind all material and feed it back to the production process again without risk of contamination.

- Super Silent – No More Noise – With MCT base (Mineral Composite Technology) the vibrations from the cutting process is absorbed. The solution equipped with integrated loop control capture a lot of the granulation noise giving a convenient working environment with less than 80 dB(A) (can depend on material/application etc).

We know that the difference between profit loss in the thermoforming industry will often come down to how efficiently you can recycle. All granulators can handle in-line skeleton waste, but with Rapid ThermoPRO you can get more from your raw materials whilst doing less manual work.

There’s no need to separately handle start-up waste, just run everything directly into the granulator, and benefit from increasing your profit margins.

Integrated loop design

The ThermoPRO has three different loop solutions that can handle start up products in the web up to 200 mm height.

- Integrated loop

- External loop

- Free standing loop

Super sound proofed

The Integrated loop control provides maximum sound insulation and reduce the noise level to under 80 dBA (depending on material, application etc.).

High quality regrind

A key is to generate high quality regrind that can be fed back into the production process again without affecting the production negatively. The Rapid ThermoPRO is 100 % developed to maximize regrind quality for Thermoforming applications.

Heavy duty roller feeder – Products up to 200 mm

Easily compresses and grind start up cups and products in the web.

Roll feeder are heavy duty design to provide a trouble free in line operation.

No extra handling, no contamination of material – just run start-up web directly into the granulator.

Inspection window with lights

A very safe and simplified solution for operator to monitor operation and when starting up the feeding of granulator.

Mineral Composite Technology Base, MCT

A mineral composite filled base to lower the center of gravity and absorb stress during operation lower the noise and vibrations even in the toughest applications.

Side feed inlet

Scrap products can be fed into an optional side feed inlet, 120x120 mm opening.

Additional fixed knives

To increase throughput an extra fixed knife can be added.

Five blade rotor

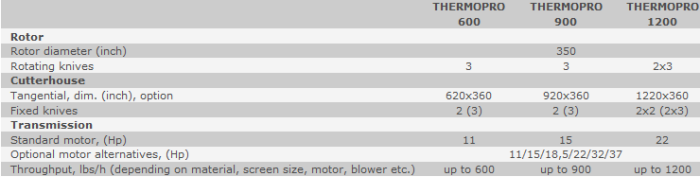

The ThermoPRO come with a 3-blade rotor in standard configuration. To add extra capacity get the 5-blade instead adding more throughput.

Professional knife setting jig (for 3- and 5-blade rotor)

To minimize downtime and to achieve the exact knife gap, required for high quality regrind production, the knife setting jig is a useful tool. This optional jig is much more precise compared to the small jig that come with the machine.

Level indicator

To protect against build up of material in bin, and possible over heating of granulator, a level indicator is useful. Can be set to different levels of functionality, basic warning signal or stopping granulator.