Tenmat Firefly - Refractory Products

High performance, low thermal conductivity Refractory Thermal Insulation for all hot processes.

A range of refractory 3 dimensional products based upon inorganic minerals and fibres bonded with colloidal silica produced by a vacuum forming process and papers produced by a water based paper process.

TENMAT Refractory Materials are available in board, shape and paper formats with low thermal conductivity (K value), less than 0.05 W/mK, and total immunity to thermal shock.

Application temperatures up to 1400 °C depending upon the grade chosen. At densities as low as 180 kg/m3 products are available in rigid and flexible forms.

All exonerated refractory products and materials are in accordance with the European Directive 97/69EC on Classification, Packaging, and Labeling of Dangerous Substances.

TENMAT Refractory Materials are used as:

- Oven and Furnace Insulation seals and gaskets (RF1000)

- Candle and Big Tube Filters for Hot Gas Filtration (CS1150/CS1155)

- Seal for pressurized gas filtration (RF1000L)

- Heater blocks for scientific and laboratory equipment (CS1150 )

- Foil wrapped refractory boards for scientific and laboratory equipment (RF1000FL )

- Aluminium processing pouring nozzles (CS1150)

- Explosion Panels (CS1155)

- High temperature induction furnace tubes and shells (RF1400 )

Aluminium Industry

Aluminium primary production and secondary processing plants benefit from the use of TENMAT`s extensive range of products wherever heat must be contained, electrical energy controlled or wear resisted. TENMAT products offer cost effective solutions to improve energy utilisation, reduce weight and operating costs and increase life cycle operation.

- SINDANYO L23 is used in the potroom in strip form between pot covers and cathode frames and in pad or plate forms between the anode support, the control gear and the super structure.

- SINDANYO H91 is an ideal material for crust breaker discs, busbar and primary frame insulation and door frames.

- ARCLEX provides the necessary electrical insulation of the cathode frame on its concrete base and to insulate busbars from the steel retaining and cathode frames.

- FIREFLY FF700 MILLBOARD is a popular choice for many sealing requirements including syphon tube gaskets in molten metal transfer equipment.

- FIREFLY FF700 MILLBOARD provides the insulating layer between the crucible and its hot face refractory lining, reducing heat losses thereby maintaining melt temperature longer. It is also used underneath the pots. FF700 possesses the necessary strength to be used as a permanent former when casting concrete.

- Inside the pot FIREFLY FF700 MILLBOARD shields the anodes in order to exclude alumina whilst gas heating takes place during start up. Once operating temperature is reached the millboard becomes a sacrificial component in the pot.

- RF1000 grade products are used as the insulation in crucibles, transport ladles and launder systems ensuring cost effective maintenance of liquid metal temperature for long periods of time.

- CS1150 pouring nozzles have replaced conventional calcium silicate and cast iron tubes for flow control of liquid aluminium.

- NITRASIL greatly extends the working life of graphite shafts used in rotary degassing equipment.

- NITRASIL is hard and wear resistant. Its use as seats and pistons in valving operations ensures trouble free performance.

- REFRAVER is used to resist attacks by fluorine in electrical and thermal environments.

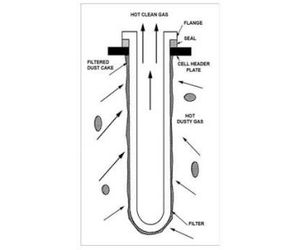

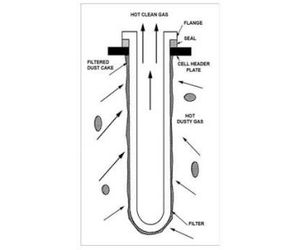

Hot Gas Filtration

TENMAT high temperature filters are made out of inorganically bonded granular minerals, providing 3 times the strength of ceramic fibres.

TENMAT hot gas filter elements are HEPA rated filter tubes developed for operating temperatures up to

1150 °C.

TENMAT manufactures a wide range of element designs in a choice of exonerated refractory materials tailor-made to customer requirements.

Without the use of asbestos or ceramic fibres, TENMAT Candle and Big Tube filters comply with the highest environmental emission standards worldwide.

Applications for TENMAT Hot Gas Filters:

Atmospheric Pollution Control

- Incineration of industrial, clinical and chemical waste

- Incineration of animal carcasses

- Soil remediation

- Cement and brick manufacture

- Metallurgical processing - ferrous and non-ferrous

In Line Equipment Protection

- Pressurised Gasification - Syngas Cleaning

- Biomass Gasification

- Pyrolysis

- Heat Exchanger Protection

- Catalyst Life Extension

Benefits and Advantages:

- High temperature capabilities up to 1150 °C

- High filtration efficiency - Typically 99.99%

- Resistant to most chemicals

- Thermal shock resistant

- Cleaned by reverse pulse

- Self supporting - no metal cage needed

- Totally incombustible - spark and fireproof

- Hot gas energy recovery

- Improve process efficiency

Plant Engineering:

Filter plant engineering will depend upon a number of key conditions, including the required temperature of operation, the gas volume and the chemicals involved. TENMAT can assist you with the filter design or recommend HGF system builders.

Request our `INSTALLATION AND OPERATION MANUAL for TENMAT Hot Gas Filters` for advice and a visit from our Product Manager at an early stage. It could save you time and money.

Proven Solution:

With over 300,000 elements sold worldwide, TENMAT has supported 200 plants in over 40 countries with its advanced technology, helping them to significantly reduce emissions and optimize heat recovery.

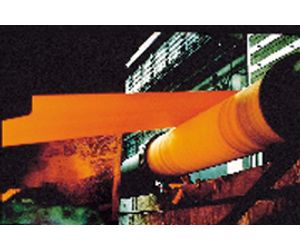

Molten Metal Processing

Molten metal processing plants worldwide benefit from the use of TENMAT`s extensive range of high temperature materials.

TENMAT manufactures a wide variety of materials for thermal insulation, electrical insulation, gasketing and molten metal handling. Typical applications for TENMAT high temperature materials include pouring nozzles, tap out cones, molten metal transfer pump components, crust breakers, gaskets and many others.

SINDANYO, TENMAT`s high temperature cement boards are the ideal materials for crust breaker discs, busbar and primary frame insulation and door frames.

FIREFLY Millboard is a popular choice for many sealing requirements including syphon tube gaskets in molten metal transfer equipment, centrifugal casting, ladle gaskets and plate rings.

CS1150, one TENMAT`s top performing Refractory Products, is used as pouring nozzles and replaced conventional calcium silicate and cast iron tubes for flow control of liquid aluminium.

NITRASIL, an engineering ceramic, exhibits high mechanical strength and exceptional wear resistance capabilities. The material is primarily used for applications in contact with molten metals like rotary degassing equipment, molten aluminium handling, zinc atomisation systems, non ferrous metal handling and others.

Whether it is in the operation or maintenance of process equipment TENMAT`s products offer cost effective solutions to improve energy utilisation, decrease operating costs, reduce weight, and increase life cycle operation.

Lab Instruments and Analytical Equipment

Manufacturers of Analytical equipment which require materials to exhibit good integrity and inertness at high temperatures often turn to TENMAT.

NITRASIL R, our Silicon Nitride material finds applications operating at up to 1100 °C whilst maintaining good strength and integrity and resistance to oxidation. Where induction heating is used as the heating mechanism NITRASIL R is also a material of choice since it is not affected by electromagnetic fields. Typical areas of application are mineral analysis equipment and precision measurement equipment.