- Home

- Companies

- Baltimore Aircoil Company

- Products

- BAC - Model VXC - Refrigerant ...

BAC - Model VXC -Refrigerant Condensers

Since 1978, thousands globally installed, proving the VXC condenser reliability. Fans, motor and drive system (V-belt) are located in the dry air, preventing moisture and condensation. No external moving parts, helping it withstand the toughest weather. Various corrosion-resistant materials, including the unique Baltibond hybrid coating for guaranteed long service life. Optional extended surface coil with steel fins for dry operation.

Ideal for a quiet operation

- VXC evaporative condensers include quiet internal centrifugal fans for minimal surrounding noise.

- Single-side air inlet, and a quieter condenser rear for more noise-sensitive areas.

- Cut operation noise still further with factory-designed and tested sound attenuators or silencers.

More compact

- Compact design for confined spaces,

- Single-side air inlet lets you install next to solid walls,

- Units housable indoors thanks to centrifugal fans allowing intake or discharge ductwork.

Reduced shipping, rigging and installation costs

- VXC units are factory-assembled. We ship larger models in 2 sections to reduce the size and weight of the heaviest section for easy on-site assembly with smaller cranes

- Single fan side requiring fewer motor starters to install and wire.

- VXC offers high capacity and minimal operating weight. Save on steel supports, both underneath the equipment and in the building itself for rooftop installations.

- VXC-C models can be container-shipped (in 10’ containers). Fan enclosures shippable loose in the condenser bottom section for easy on-site assembly.

- Reliable

- Quiet

- Compact

- Tight enclosures and installations requiring a single air inlet

- Limited plan area installations

- Indoor installations

- Sound critical installations

- Dry operation in winter time

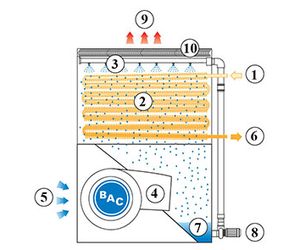

Vapor (1) enters through a evaporative condensing coil (2) and gets water sprayed on by the spray system (3) at the top of the condenser. At the same time the centrifugal fan (4), located at the bottom of the unit, blows ambient air (5) upwards through the condenser. During operation, heat is transferred from the internal circuit coil to the water, and then to the atmosphere as a portion of the water that evaporates. The condensed vapor then exits the unit (6). The sump (7) or basin collects the water. The spray water pump (8) recirculates the water up to the water spray system. The warm saturated air (9) leaves the condenser through the drift eliminators (10), which remove water droplets from the air.

Material options

- Heavy-gauge hot-dip galvanized steel is used for external unit steel panels and structural elements featuring Baltiplus Corrosion Protection.

- The unique Baltibond hybrid coating is an optional extra. A hybrid polymer coating for longer service life, applied pre-assembly to all hot-dip galvanized steel components of the unit.

- Optional stainless steel panels and structural elements of type 304 or 316 for extreme applications.

- Or the economical alternative: a water-contact stainless steel cold water basin. Its key components and the basin itself are stainless steel. The rest is protected with the Baltibond hybrid coating.

Heat transfer media

- Our heat transfer media is a condensing coil. In comprehensive lab thermal performance tests, it showed proved thermal cooler performance and offers you unrivalled system efficiency.

- The coil is constructed of continuous length of prime surface steel, hot-dip galvanized after fabrication. Designed for maximum 23 bar operating pressure according to PED. Pneumatically tested at 34 bar.

-

All hot dip galvanized coils are delivered with BAC`s Internal Coil Corrosion Protection, to ensure an optimal internal corrosion protection and guaranteed quality.

Try our VXC coil options:

- Extended surface coils with selected rows, finned at 3 to 5 fins per inch and hot-dip galvanized after fabrication, for dry operation during winter time.

- Multiple circuit coils (split coils) for your halo carbon refrigerants, maintaining individual compressor systems. Or use it for compressor jacket water or glycol cooling.

- Stainless steel coils are in type 304L or 316L.

- High pressure coils are designed for 28 bar operating pressure and pneumatically tested for 40 bar. Hot-dip galvanized after fabrication.

All coils are designed for low pressure drop with sloping tubes for free drainage of fluid.

Air movement system

- With motor-driven centrifugal fan and a V-belt drive. You can easily remove the entire motor base for proper belt tensioning to ensure constantly correct belt alignment. Together with the heavy duty fan shaft bearings this guarantees optimal operational efficiency. Single- and multi speed available.

- Centrifugal fan(s) are forward-curved and nearly noiseless. Overcome external static pressure! Use sound attenuators and duct work etc. for air intake/discharge with no loss of thermal performance!

- Our drift eliminators come in UV-resistant plastic, which will not rot, decay or decompose and their performance is tested and certified by Eurovent. They are assembled in easily handled and removable sections, for optimal internal access.

- Steel eliminators, protected with the unique Baltibond hybrid coating, for optimal corrosion protection, are also available for specific applications.

Water distribution system

These consist of:

- A header and spray branches with wide non-clog plastic nozzles, secured by rubber grommets. You can easily remove, clean and flush both nozzles and spray branches.

- A cold water basin with:

- strainers which are easy to lift out and the anti-vortexing device also helps stop trapped air

- mechanical make up

- circular access door - Close coupled, bronze fitted centrifugal spray pump with totally enclosed fan cooled (TEFC) motor. Bleed line with metering valve installed from pump discharge to overflow.