- Home

- Companies

- Turner EnviroLogic, Inc.

- Products

- Turner EnviroLogic - Regenerative ...

Turner EnviroLogic - Regenerative Thermal Oxidizers (RTO)

For very low VOC concentrations, Turner EnviroLogic recommends a Regenerative Thermal Oxidizer (RTO) that is capable of up to 99% destruction efficiency and up to 95% heat recovery. A two-chamber, industrial RTO equipment is the most cost effective selection. Individual heat recovery chambers are filled with a ceramic heat sink media. Incoming VOC laden air enters one of the chambers where the gas is raised close to the light-off temperature by heat stored in the ceramic heat sink media. The heated gas is then burned in the top combustion chamber. These hot gases are then routed through a second chamber where the heat is again stored in the ceramic media. During the next operating cycle of the industrial RTO equipment, the gas flow though the unit is reversed by switching of a proprietary switching valve.

Turner EnviroLogic’s CrossFire RTO converts volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) to carbon dioxide and water vapor through the process of high temperature thermal oxidation. Up to 95% of the thermal energy needed for oxidation is recovered in the two-chamber RTO.

Exhaust gases containing dilute concentrations of VOCs are delivered to the RTO via a forced draft fan that is controlled by a VFD to maintain constant draft control. A proprietary single-blade switching valve directs the gases to one of two heat recovery chambers where the gases are preheated by heat stored in structured ceramic media. Once preheated, the gases are brought up to oxidation temperature in a combustion chamber with heat from a small supplemental burner. From the combustion chamber, the cleaned gases pass down through the second heat recovery chamber where the gases give up heat that is stored in the structured ceramic media in the second heat recovery chamber. The cooled, clean gases pass again through the switching valve and out to atmosphere via an exhaust stack.

Sophisticated PLC controls determine the optimum time to switch the position of the switching valve reversing the flow of gases through the RTO. The heat recovery chamber that was the inlet chamber now become the outlet chamber and vice versa.

Turner EnviroLogic uses the temperature differential between inlet and outlet to determine when to switch the position of the switching valve. This is far superior to RTOs that base switching on time. Since we use differential temperature, our RTO always achieves the highest heat recovery possible saving the greatest amount of energy. If the concentration of VOCs in the exhaust gases is high enough, the RTO controls will shut the natural gas off completely and allow the RTO to operate in a self-sustaining, fuel free mode. As the VOC concentration decreases natural gas is re-introduced to the burner which then automatically re-lights.

Turner EnviroLogic CrossFire RTOs are applied in applications where VOC concentrations are as low as 3% of the Lower Explosive Limit (LEL) or as high as 25% LEL. We employ various methods of heat rejection to maintain optimum performance. As VOC concentration increases, the natural gas is reduced to the burner - all the way to zero if needed. If VOC concentration continues to increase, a dilution air damper allows fresh air into the RTO for cooling. When VOC concentrations are very high, a hot-gas by-pass damper opens so that hot gases are directed directly from the combustion chamber to the exhaust stack.

Destruction efficiencies up to 99% are achievable with the RTO. Key to high efficiency is the very fast action of the single-blade switching valve and its close proximity to the heat recovery chambers. Single-blade switching valve design eliminates the potential for timing problems associated with operating two independent poppet valves. This means faster switching and reduced interruption in air flow.

Our fast acting switching valve is located directly between the recovery chambers eliminating large inlet and outlet plenums. This close proximity ensures that the volume of untreated gas that “puffs” during switching is kept to an absolute minimum.

Access to the electrical sub-panel, gas train components, main burner and pilot and switching valve actuator is easily made without having to climb ladders or work from platforms. Since these components are located underneath the housing of the CrossFire RTO, service can be done even during inclement weather.

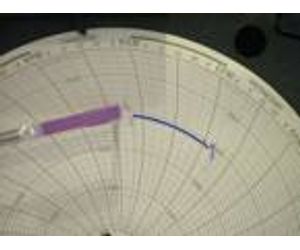

All safety and operational aspects of the CrossFire RTO are controlled by an Allen-Bradley Compac Logix PLC with a PanelView Plus touch screen graphical interface. A single button starts and stops the CrossFire RTO. All burner light off operations such as purging, functional checks of all safety interlocks, lighting of the pilot, main burner lighting and main flame verification are automatic. All set points are adjusted from a single, password protected, screen while two screens are dedicated to monitoring temperature trends. All operational faults are logged over time and displayed to aid troubleshooting.