- Home

- Companies

- Regulator-Cetrisa

- Products

- Regulator Cetrisa - Model R-SPM - Eddy ...

Regulator Cetrisa - Model R-SPM -Eddy Current Separators

The Eddy Current Separator (R-SPM) is able to separate the Non-Ferrous metals from the rest of the materials due to its studied magnetic assembly called the “Inductor Drum”, which rotates at high speed. When a Non-Ferrous Metal crosses the induced magnetic field, it undergoes a repulsion effect and jumps a certain distance ahead of the Foucault drum and away from the rest of the materials.

Aware of the serious environmental problem, REGULATOR-CETRISA has developed a complete line of Equipment for Separating and Recycling NON-Iron Metals by Eddy Currents (R-SPM).

The physical principle of the Eddy currents is based on an alternative magnetic field, meaning, in a magnetic field where the North and South Poles alternate.

When non-iron metal is subject to an alternative magnetic field, internal currents will be created that are called Eddy Currents. These Eddy Currents generate a magnetic field that opposes the magnetic field generated by the drum. This strong opposition of magnetic fields provokes repulsion between them and therefore the non-iron metal will be literally thrown off its natural path, being separated from the rest of the materials.

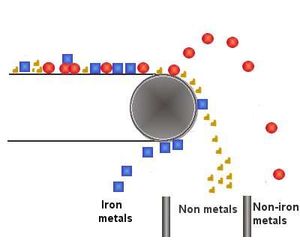

In the attached figure of the R-SPM equipment, the behaviour that the different materials will have can be observed:

- NON-Iron Metals: They go through an effect of repulsion and jump a certain distance ahead of the Foucault Drum.

- Iron metals: They are attracted and trapped by the Foucault Drum and are separated by its lower part and behind the drum`s shaft.

- Non-metals: They are not influenced and follow the natural parabolic falling path.

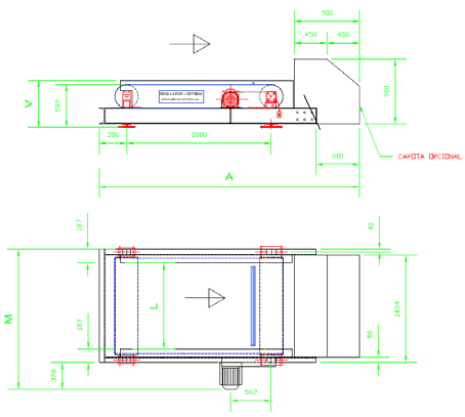

The Separator of NON-Iron Metals by Eddy Current (R-SPM) has a robust metallic structure, which is the support for two rollers: the pulling roller, a belt drive that moves the conveyor belt, and the head roller, or Inductor Drum, responsible for generating the Eddy Currents. To obtain a high alternation of magnetic poles, the drum rotates at a high speed. REGULATOR-CETRISA has equipment with admissible rotation speeds higher than 3,000 r.p.m.

The Inductor Drum is made up of two drums, where the interior drum is the generator of the Eddy Currents, and the exterior drum which rotates at the transmission speed of the conveyor belt. The exterior drum is made of material that is completely transparent to the magnetic and induction fields, in order to avoid the screen and dispersion effects. This way, the loss of IR2 is reduced to zero.

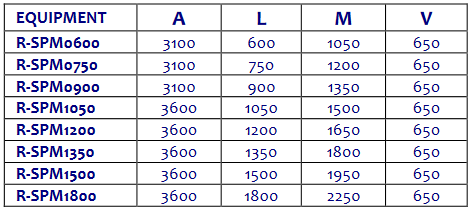

REGULATOR-CETRISA offers equipment with very different configurations (R-SPM, R-SPM/AD, R-SPM/AF, RSPM/AM…) and effective working widths up to 2,000 mm, adapted to the materials that should be processed. For this reason that there is working equipment in many different sectors, such as: Urban Waste Plants, WEEE, ELV, wood, glass, plastic, etc.

The parameters corresponding to the material`s aggregate grading, its circulation velocity, the effective working width, the Inductor Drum, its rotation speed, etc., are parameters that are interrelated. Through the optimum adjustment of these, we will obtain the best result and the best separation. The equipment will also adjust to the client`s needs: legs, motor side, colour, etc.

REGULATOR-CETRISA uses all of its experience to determine the ideal equipment for every application. Besides its own experience from innumerable applications, the technical department evaluates all the necessary parameters, such as: flow, density, humidity, aggregate grading, etc.

REGULATOR-CETRISA offers the possibility of testing materials in its own facilities, where the client can verify the effective separation of the metals. This way, we can ensure satisfactory results.

REGULATOR-CETRISA, thanks to its continued investment in R&D, offers the best technology for integrating equipment and systems into its processes and Complete Turnkey Installations.