- Home

- Companies

- Shenyang EMT Pigging Technology Co., ...

- Products

- EMT - Removable Pig Signaller With ...

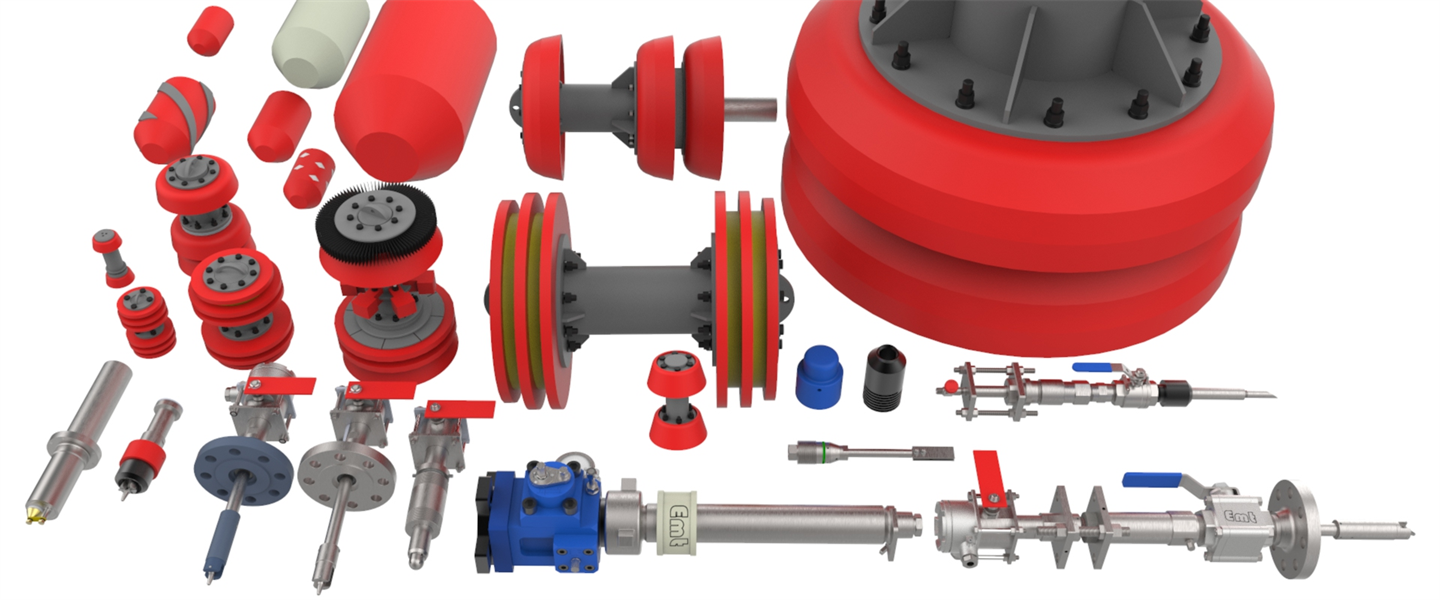

EMT - Removable Pig Signaller With Flange

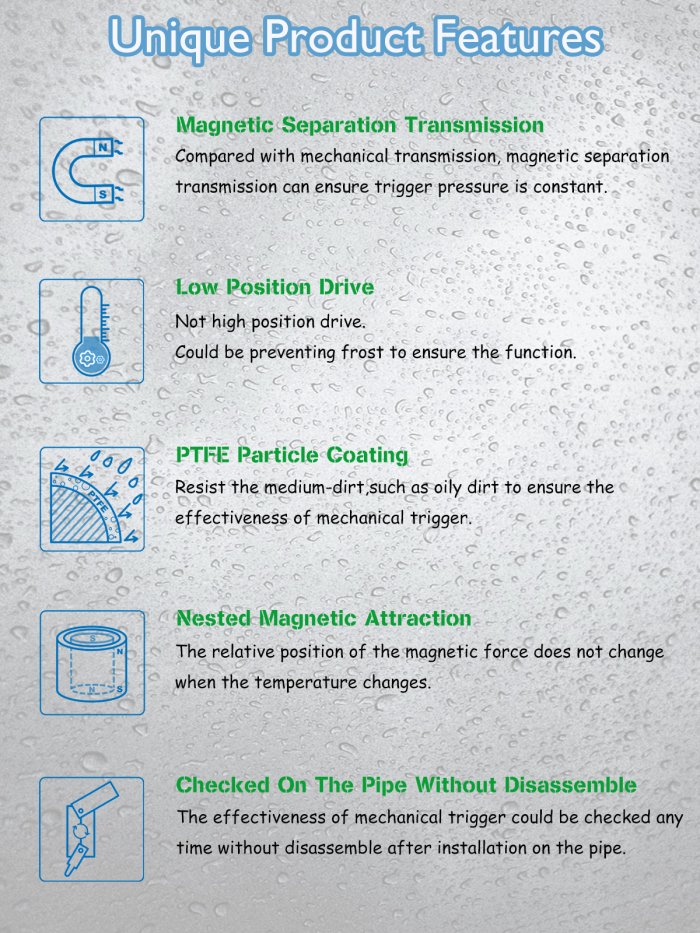

The Removable Pig Signaller With Flange is designed for monitoring the movement of pipeline pigs through various types of pipelines. This device can be chosen for either bi-directional or uni-directional pigging processes according to user requirements. It is positioned at critical points like pig launching and receiving stations to provide a reliable indication of pig passage. Key features include a withstand pressure of 6.4MPa and adaptability to pipeline diameters over 150mm. It operates efficiently within temperature ranges of 0°C to 80°C. Additional functionalities include optional remote control signaling, and it supports multiple remote interface types such as 1/2NPT (F), 3/4 NPT (F), and M20 * 1.5 (F). The Pig Signaller with flange is constructed with a mechanical contact type structure, ensuring a simple, low-cost, yet intuitive and reliable operation. It is useful for long-distance pigging processes, sweeping operations, and provides precise passage time notifications to aid operators during pipeline operations. The product is ISO9001, ISO45001, and ISO14001 certified which underscores its compliance with international standards.EMT Pig signallers are used to provide confirmation of the movement of pipeline pigs through a pipeline. Pig signallers are normally positioned at both the pig launching and pig receiving stations and at key points along a pipeline.

Removable Pig Signaller With Flange Technical parameters:

withstand pressure: 6.4MPa

Installation height on the pipe: 340mm (can be raised)

Remote control signal (optional)

Remote interface 1/2NPT (F) or 3/4 NPT (F), M20 * 1.5 (F)

Adaptable temperature range: 0°C-80°C

Adapt to the pipe diameter: 150mm or more

Scope of application: various oils, gases, water and new pipes that can be welded

In the process of long-distance pipeline pigging, sweeping, etc., it is fixed at the designated position of the pipeline, and the mechanical structure is used to transmit the passage of the pig in the pipeline, and then the special clock or pointer secondary signal source is provided to the operator. Whether the pig passes or not, and shows the exact time when the pig passes, so that the operator can guide the process conversion.