- Home

- Companies

- Natural Seawater Desalination Ltd

- Products

- Natural Seawater Desalination - Reverse ...

Natural Seawater Desalination - Reverse Osmosis System

Today we have the internet, and any person can check the facts on a worldwide basis. The first basic truth about reverse osmosis as a process for getting pure water from sea water: It is more expensive than city water (rain water). None of the cities facing the sea shores, in any country all over the whole world, can exchange river or rain water for water obtained by seawater desalination by reverse osmosis. Not even a plant which is consuming a lot of pure water, located next to the sea shore, can rely in getting pure water from reverse osmosis, as long as there is another source of rain water.

HOWEVER, ALL THE SCIENTIFIC REPORTS DESCRIBING REVERSE OSMOSIS, WITHOUT ANY EXCEPTION, ARE CLAIMING THAT PURE WATER OBTAINED BY REVERSE OSMOSIS IS CHEAPER THAN CITY RAIN WATER?????????????????

If pure water from reverse osmosis is cheaper, then there would be someone who would dare to sell this water in cities facing sea shores???? However not a single identity on a worldwide basis could avail such water....

The truth about reverse osmosis: New membrane elements offer low pressure drop at the beginning, next after a month and more, this pressure drop through these membrane elements increases a lot. However all scientific calculations are based on initial new conditions of membranes. Also new membrane elements can generate a high percentage of pure water, after a short period of time this percentage decreases, still also design calculations are based on initial new conditions of membranes, and we have to pump more water. The big obstacle remains that these membranes are expensive; no one would dare to exchange these membranes when he would see that the needed pressure drop is increasing.

Energy consumption: Reverse Osmosis consumes 5.6 kWh/m cube for new membrane elements. This RO energy consumption does not include the need of micro pre-filters which are not needed for our process, which brings the normal operational energy consumption of Reverse Osmosis to 8 kWh/m cube, while Natural Seawater Desalination energy consumption is less than 2.5 kWh/m cube.

Our production line is mainly for units generating potable water at the rates of 100 cubic meters/hr, and 10 m3/hr; smaller units of 1 m3/hr can be manufactured upon agreement. Our manufacturing facility is in Sarnia, Ontario, Canada. Our units come with pumps with stainless steel impellers, and an extra spare pump.

Our units come with an inlet filter. In case the water to be treated contains calcium salts (hard water), then we will provide a water softener for very low extra charges.

We would like to clarify that our seawater desalination units are practically maintenance free, with practically no renewable items.

We offer for new projects a promotion of one unit 1 m3/hr for only US$ 10,000 to help the project management evaluate our equipment physically on their project construction site.

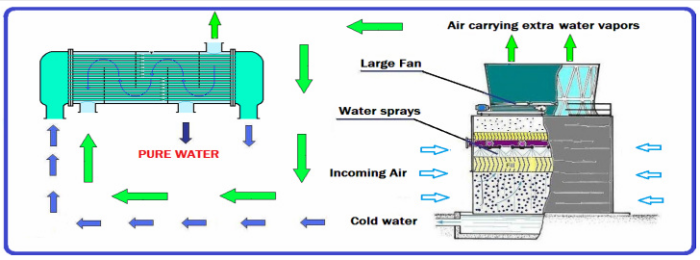

In a water cooler, air is flowing through water sprays. Air gets saturated with water vapors, and water gets cooler by vaporization. Next we take these two streams to exchange heat in a heat exchanger. We will get pure condensed water at the bottom of heat exchanger.

BENEFITS OF ROOM TEMPERATURE VAPORIZATION OVER EVAPORATION AT THE BOILING POINT.

In room temperature vaporization: the heat of vaporization is obtained from the bulk of water body, cooling water, without any need of any external energy. While in case of evaporation at the boiling point the heat needed to evaporate water is totally obtained from an external source of energy.

This is an unmeasurable merit for the process of Natural Seawater Desalination, where there is no need for any external source of energy, while the cold water is next used to condense water vapor.

COMPARISON WITH REVERSE OSMOSIS.

- NO EXPENSIVE EQUIPMENT: No excessive high pressure pumps, no expensive membrane elements.

- NO INCREASE IN PRESSURE DROP: After using membranes elements for a short while, pressure requirements start to increase.

- NO DECREASE IN PRODUCT FLOW RATE: Still after using membranes for a short while the product output flow rate starts to decrease.

- NO DANGEROUS CHEMICALS ADDED: Reverse osmosis consumes constantly sulfuric acid as anti scaling agent.

- ON THE CONTRARY: Very simple design, at very mild conditions allowing very cheap materials to be used:

- HEAT EXCHANGER operates at a temperature lower than 50 C allowing the use of plastic piping.

- WATER COOLER packing can be very simple Rashig rings which are simply a plastic pipe cut into small equal segments.