- Home

- Companies

- Monitor Technologies, LLC

- Products

- TrueCap - Model MK2 - RF Capacitance ...

TrueCap - Model MK2 -RF Capacitance Level Sensors

TrueCap RF capacitance sensors offer effective point level indication with excellent reliability and advanced features. Monitor’s complete line, featuring models MK-2 and MK-2e, provides you with the most practical solution for your application...from a feature-rich version to a cost-conscious version. Monitor’s RF capacitance probes are designed to provide a high level of sensitivity, stability and durability for powder and bulk solids applications, as well as liquid and slurry applications. Monitor’s two-year warranty stands behind every TrueCap sensor.

- Maximized Reliability via Smart Sensing Algorithms Including “Self- Validating” Fail-Safe Protection

- Simple, Convenient Push-Button Calibration and Test

- Driven Shield Technology Overcomes Material Build-up

- Externally Viewable LED Sensor Status Indicator (Ordinary Loc. Unit)

- Superior 0.5pF Sensitivity

- Enhanced Temp. Compensation

- Universal Power Supply

- Now Available...Quick-Connect Tri-Clamp Process Connection.

A radio frequency is applied to the probe and is continually analyzed to determine the influence caused by the surrounding environment. As material contacts the probe, the radio frequency shifts indicating an increase in capacitance (C). The active probe of the unit and the vessel’s wall make up the two plates (A=area) of a capacitor which are separated by a fixed distance (d). The probe’s insulator and surrounding air provide the dielectric material (with dielectric constant “K”). As the air (K=1.0) is displaced with any other material (K > 1.0), the capacitance effect (C) is enhanced, thereby changing the application’s impedance. This influence is measured within the circuitry and compared to a reference established by the sensitivity setting. The setting determines how much influence must be present before the output changes. The driven shield section of the probe enables the circuitry to ignore product build-up on the probe that would otherwise cause false sensing.

The driven shield is activated with the same radio frequency potential as the sensing probe. Since current can not flow between identical potentials, the driven shield blocks current flow from the active probe to the vessel wall through the material build-up, thereby eliminating the sensing of the material build-up.

TrueCap RF capacitance point level sensors are versatile devices providing high and low level readings in bins, silos, tanks, hoppers, and other vessels. TrueCap’s superior sensitivity range allows users to properly adjust units to meet the needs of a wide variety of applications. Whether your application is for a powder, liquid, granular solid, or viscous material, the TrueCap product line offers the right solution.

Typical Applications include, but are not limited to:

- Feed / Grain

- Chemicals

- Pellets

- Plastics

- Liquids

- Pharmaceuticals

- Rubber

- Wastewater

- Sand

- Food Ingredients

- Slurries

- Cement

- Powders

- Paint & Coatings

- Coal

- Granular Solids

- Oils

- Paper Pulp

- Feed / Grain

- Chemicals

- Pellets

- Plastics

- Liquids

- Pharmaceuticals

- Rubber

- Wastewater

- Sand

- Food Ingredients

- Slurries

- Cement

- Powders

- Paint & Coatings

- Coal

- Granular Solids

- Oils

- Paper Pulp

The TrueCap Model MK-2 RF capacitance point level sensor is a proven problem solver used to ensure maximum performance and reliability, minimizing downtime of operations.

- Micro-controller based for maximum reliability & performance

- Push-button calibration, sensitivity selection & self-test

- Automatic temperature compensation for unmatched calibration stability

- Superior 0.5 pF sensitivity ensures reliability

- Build-up immunity helps eliminate false signals

- High intensity LED indicating light (Ordinary location sensors only)

- Universal power supply minimizes versions

- Available hazardous location approvals with intrinsic safety

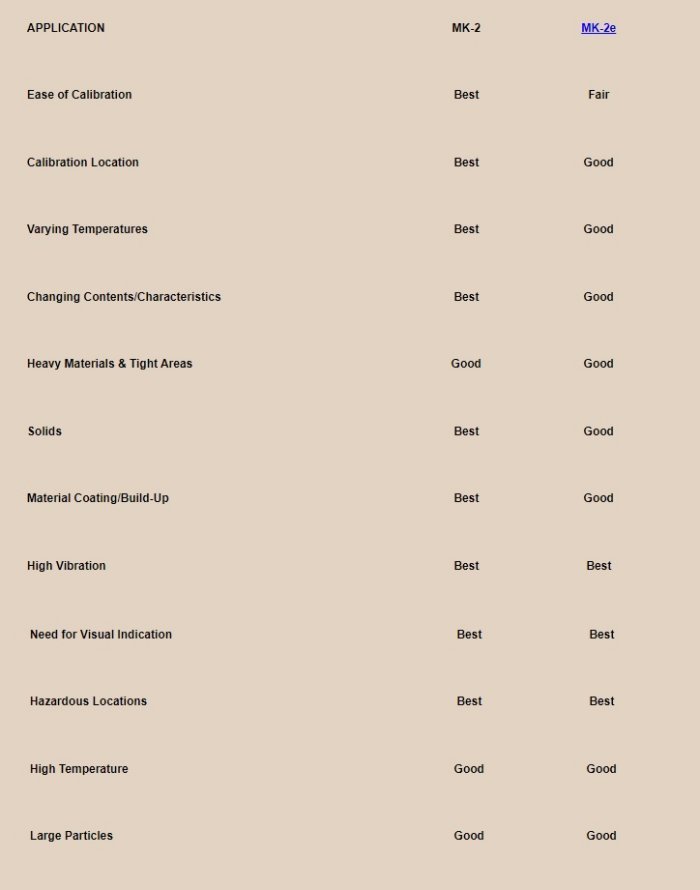

Monitor offers the market an unmatched selection of RF Capacitance point level sensors. Several factors should be considered when selecting the proper TrueCap® RF capacitance point level sensor.

EASE OF CALIBRATION

Many applications are well served by the manual calibration of the MK-2e, but only the MK-2 offers the extraordinary convenience of push-button calibration, sensitivity and self-test. VARYING

TEMPERATURES

It is important that the calibration of a probe remains stable during swings in the process and ambient temperatures. The MK-2 automatically adjusts its calibration to account for temperature changes providing maximum reliability.

CHANGING CONTENTS/CHARACTERISTICS

TrueCap sensors can be calibrated to the material with the lowest dielectric constant (usually the driest material) in order to sense all products which could enter the bin. However, sometimes the need for re-calibration is unavoidable, making the MK-2 with push-button calibration and an available remote calibration module the best choice.

HEAVY MATERIALS & TIGHT AREAS

Some applications require compact, sturdy probes for heavy materials or confined spaces. The MK-2 and MK-2e offer a stub probe for extra durability for heavy products and a compact design for tight areas. Both models also use heavy duty 3/8 inch (9.5 mm) diameter probes. SOLIDS All TrueCap sensors can sense solid materials, but be careful to also look at all application parameters.

MATERIAL COATING/BUILD-UP

Many liquids, slurries and sticky bulk solids tend to cling to probes. Product build-up immunity through a driven shield design is a must. The MK-2 and MK-2e provide product build-up immunity and can typically be used with these materials. HIGH VIBRATION When locating sensors near vibrators, bin dischargers or other vibrating equipment, the split architecture version is recommended.

UNIVERSAL POWER SUPPLY

Minimizing the number of variations can maximize value for OEMs and product resellers. The MK-2 is the only TrueCap sensor that provides this capability. NEED FOR VISUAL INDICATION Both the MK-2 and the MK-2e are provided with a high intensity LED indicator on the housing (Ordinary location integral sensors only).

HAZARDOUS LOCATIONS

The MK-2 and MK-2e are available approved for Class I and Class II hazardous locations. See “Specifications” for details.

HIGH TEMPERATURE

For applications up to 450°F, (232°C) the MK-2 and MK-2e offer stainless steel mounting connections which act as thermal barriers and a split architecture version which completely removes the electronics from the process.

LARGE PARTICLES

Large particles can leave air gaps which could lead to inaccurate readings. However, smaller particles and fines usually fill in the gaps.

FOOD GRADE PROBE

Most probe variations are available with nylon insulators for food grade applications. Food grade probes are usually outfitted with the stainless steel connection.

HAZARDOUS APPROVALS

Most MK-2 models are offered with explosion proof housings and intrinsically safe probes thereby meeting requirements for Class I and Class II environments. See “Specifications” for details.

A 3/4” NPT 316 stainless steel mounting connection for applications requiring material compatibility enhances the effectiveness in food grade or corrosive applications.

For applications involving high temperature or vibration, the probe and electronics are housed in separate enclosures mounted 12 feet (3.6 m) apart or more depending on the application, thereby removing the electronics from the stressful conditions. All adjustments are performed at the remote electronics.

- Power:

- 48-240VAC ±10%, 3VA, 50/60Hz

- 24-48VDC ±10%, 3W

- Altitude: 6562ft (2000m) max

- Installation Category: II

- Pollution Degree: 4 (reduced to 2 by enclosure) Suitable for indoor/outdoor use

- Ambient Operating Temp: -40°F (-40°C) to +150°F (65°C)

- *Internal Bin Temp:

- To +176° F (+80° C) w/alum. mount (

- To +400° F (+204° C) w/SS mount (

- Output Relay: DPDT, 5A @ 250VAC, 30VDC maximum

- Indicators:

- “DET” yellow LED illuminates when material is sensed

- “ OPR” red LED illuminates to indicate output switching

- “ CAL” green LED illuminates to indicate proper calibration

- “ SEN” bank of four LEDs indicated the sensitivity setting

- External Indicators: Red and green LEDs indicating power and operating mode (Ordinary location units only)

- Sensitivity: Switch selectable 0.5pf, 2.6pf, 8.3pf, 18.0pf

- Stability: ±0.01pf per degree F (±0.018pf per degree C) @ 0.5pf setting

- Time Delay: 0.25 to 15 sec single-turn adjustable for delay to activate and delay to de-activate

- Fail-Safe: Switch selectable - HI/LO

- Build-Up Immunity: Protected via driven shield to 150 ohm load

- Enclosure: Cast alum screw-on cover, beige polyester powder coat, NEMA 4, IP66

- Conduit Connection: Two (2) 3/4” NPT connections (M20 cable glands provided when 1-1/2” BSPT process connection is specified)

- **Approvals:

- CSA(US) CSA(C) Ordinary Locations, CE Mark(Ordinary location only)

- CSA(US) CSA(C): Class I Groups C & D, Exp. Proof & Intrinsically Safe

- CSA(US) CSA(C): Class II Group E, F & G, Dust Ignition Proof & Intrinsically Safe

* Influenced by mounting, material thermal conductivity and ambient temperature.

** Hazardous location approvals on units with Pipe Extension or Lagged Probes with integral electronics/probe are CSA(US/C) Class II Groups E, F & G (SS version ONLY. Hazardous location approvals are not available on the galvanized version). Hazardous location approvals for Split Architecture remote electronics are Class II, Groups E, F & G. All probe versions, except the galvanized version of the pipe extension or lagged probe unit, are Class I Groups C & D, Class II Groups E, F & G and Intrinsically Safe.

Standard/Food Grade Probe:

- Mounting: 1-1/4” NPT alum, R 1-1/2 (BSPT 1-1/2), or combo 3/4” NPT 316SS and 1-1/4” NPT alum

- Probe Material: 3/8in(9.5mm) dia. 316SS probe & guard, Ryton®-Equiv & Nylon insulators

- Probe Length: 16in (406mm) from alum mounting

- Temp (Probe Only): Ryton®-Equiv +450° F (+232° C) max; Nylon +300° F (+148° C) max

- Pressure:

- 50 psi (3.5 bar) max (alum connection);

- 150 psi (10 bar) max (3/4” NPT SS)

Stub Probe:

- Mounting: 1-1/4” NPT alum, R 1-1/2 (BSPT 1-1/2), or combo 3/4” NPT 316SS and 1-1/4” NPT alum

- Probe Material: 3/8in (9.5mm) dia. 316SS probe & guard, Ryton®-Equiv & Nylon insulators

- Probe Length: 9" (229mm) from aluminum mounting

- Temp (Probe Only): Ryon®-Equiv +450° F (+232° C) max; Nylon +300° F (+148° C) max

- Pressure:

- 50 psi(3.5 bar) max (alum connection);

- 150 psi(10 bar) max (3/4” NPT SS)

Cable Extension Probe:

- Mounting: 1-1/4” NPT alum, R 1-1/2 (BSPT 1-1/2), or combo 3/4” NPT 316SS and 1-1/4” NPT alum

- Probe Material: 1/8in(3.2mm) diameter 316 SS Teflon® jkt’d cable, Nylon insulator

- Cable Length: Customer specified from 17" (432 mm) up to 50 ft (15m) overall insertion from aluminum mounting

- Temp (Probe Only): +300° F (+148° C) max

- Pressure:

- 50 psi(3.5 bar) max (1-1/4" NPT alum);

- 150 psi(10 bar) max (3/4” NPT SS)

Pipe Extension Probe:

- Mounting: 1-1/4” NPT alum

- Probe Material: Galvanized or 316SS

- Probe Length: Customer specified from 22" (559 mm) up to 144in (3.6m) overall insertion

- Interface to: Standard or Food Grade (See applicable specs)

Lagged Housing Version:

- Mounting: 3/4” NPT 316SS

- Lag Material: Galvanized or 316SS

- Lag Length: Customer specified from 7 to 24 in (178 to 610 mm)

- Interface to: Standard Probe only (See applicable specs)

Split Architecture:

- Elec. Enclosure:

- Cast Aluminum, screw-on cover, polyester powder coat (HL MK-2 only)

- Fiberglass enclosure (OL) (MK-2 only)

- Cable: 12 ft (3.6m), 22 awg co-ax / 18 awg wire

- Max Bin Temp:

- Ryton®-Equiv probe: +450° F (+232° C);

- Nylon: 300° F (+148° C)