- Home

- Companies

- Purestream, Inc. and Purestream ES , ...

- Products

- Purestream ES - Model In-Eko - Robust ...

Purestream ES - Model In-Eko -Robust Screw Screen for Industrial Wastewater Treatment

The In-Eko Screw Screen is the perfect marriage between the Mechanical Bar Screen and a Screw Press. Specifically designed for lower flow applications (less than 1 MGD), the Screw Screen blends the screening capability of the Mechanical Bar Screen with the dewatering and pressing capability of the Screw Press. Available in standard or custom sizes as well as a wide variety of screen opening sizes, the Screw Screen is a great solution for headworks screening on smaller plants.

Constructed of 304 Stainless Steel and Fiberglass Reinforced Plastic (FRP), the Screw Screen is an extremely durable piece of equipment that will serve your facility for a long time. For cold weather climates, the Screw Screen is available with insulated and heated housings.

Due to the Screw Screen’s compact size, it is delivered in it’s own self-contained channel. The channel can be open for mounting into a concrete channel or flanged for piping. The screw press carries screened solids up the 360 ° rotating chute, giving you more options for placement of a trash can, hopper, or other means of disposal. The backwash system keeps the screw clean and can be operated manually, timed, or automatically tied in to a level sensor or probes. Screen openings are available in 1, 3, 6, and 12 mm sizes.

Maintenance is easily done by simply lifting the unit out of its channel. Each screen is provided with a mesh plate of equal opening sizes to slide in front of the flow while maintenance is being performed, so treatment will not be interrupted.

Reliable, cost-efficient protection for your critical wastewater treatment equipment

- Keeps damaging particles from entering system

- Greatly extends equipment life

- Prevents costly shutdowns

- Compacts solids for easy removal

- Provides continuous operation during routine maintenance and cleaning

- Rugged, long-life construction gives years of trouble-free service

- Saves labor and energy costs

- Stainless steel construction

- Compact design

- All functions automatically operated by ultrasonic level sensors

- Optional covers and heaters for low temperature operation

- Large filtration area with low head loss through screen

- Minimal electrical requirements

- Low water consumption backwash

- Clutch-style lift-out screen for easy cleaning

- 360-degree chute design for solids removal through bags, hoppers or trash cans

- Tough, wear-resistant polyamide nylon brush system

- Precision engineering for zero flow bypass

Screw screen extends equipment life, prevents costly plant shutdowns

A Screw Screen from Purestream ES offers the single best way to protect expensive wastewater treatment equipment – by effectively removing large solids before they can enter your plant and damage vital pumps or other hardware.

The easy-to-operate Screw Screen features a screening bar array and an automatic dewatering, screen cleaning, solids compaction and disposal system. Its high-grade 304 stainless steel and Fiberglass Reinforced Plastic (FRP) construction ensures years of quality performance with low maintenance requirements. And its flexible design allows it to be channel mounted or flanged for “hard piped” applications, with a choice of 1, 3, 6 or 12 mm screen openings. The Screw Screen is designed for the toughest working conditions, in any climate. Optional heated covers provide protection for severe winter conditions.

Screw screen saves space, labor and Energy costs; can continue operating During cleaning and maintenance

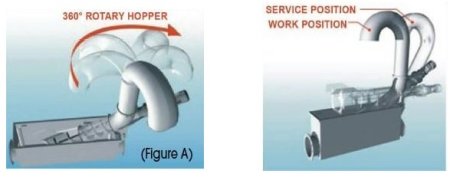

Our Screw Screen has a compact design that enables it to fit into the tightest spaces, freeing up valuable space. And its discharge chute can rotate a full 360 degrees, allowing for a waste container to be positioned in a variety of locations – or for containers to be placed side by side. (FIGURE A)

The Purestream ES Screw Screen saves valuable operator time as well, with a flexible system that can be set to function automatically or on a timed basis. It also features low electrical consumption, making it an energy-affordable, long-lasting investment.

Routine cleaning and maintenance can be performed efficiently and quickly due to the easily accessible clutch-style design that allows our screen to be lifted from its channel easily. And maintenance doesn’t need to interfere with solids removal because a temporary screening plate can be inserted in place of the bar screen, permitting continued operation.

- Raw wastewater enters the Screw Screen upstream from the treatment plant and passes through the unit`s bar screens which trap the larger solids.

- As the water level in front of the screen rises, an automatic level sensor activates the screw, brushes and backwash.

- The brushes turn with the screw, pressing and dewatering the solids before compacting them in the outlet chute.

- They are then gravity fed into a waste receptacle for disposal.