- Home

- Companies

- JDV Equipment Corporation

- Products

- JDV - Rotary Drum Thickeners

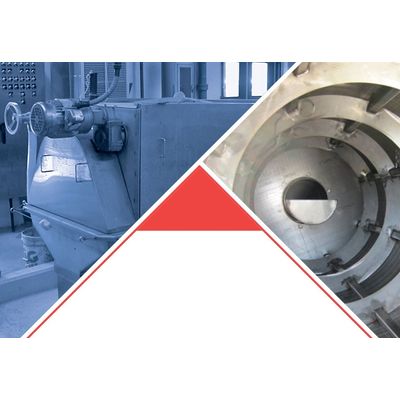

JDV - Rotary Drum Thickeners

JDV incorporated the Ralph B. Carter Company design into its growing portfolio in 1995. The drum thickener is a stainless steel design, offering a polyester filter media and direct drive system. A wide range of solids can be processed with ability of producing 5-7% TS for most applications. Rotary drum thickeners are sized to handle throughput as small as 35gpm up to 400gpm.

Removing water from solids is a primary concern for plant operators, whether it is digested sludge or raw sludge. Less water means lower overall solids disposal costs. For operators feeding digesters, removing free water from raw sludge equals increased digester efficiency and volume. The JDV Rotary Drum Thickener is also excellent for liquids separation for industry. Pulp and paper, textiles, rendering facilities, food & beverage processing, tanneries, poultry plants and other industrial wastes can be thickened using the JDV Rotary Drum Thickener.

Polymer is injected into the feed line and mixes with the thin sludge in the Floe Basin or Tank. The conditioned sludge material is then passed into the JDV Rotary Drum Thickener, which separates the flocculated solids from the water.Thickened sludge rolls out the end of the drum, while the separated water decants through the self-cleaning screen. The JDV Rotary Drum Thickener has a smaller foot print, lower upfront capital costs and lower overall operating costs when compared to other methods of thickening material.

- Self Cleaning Rotary Screen, reducing

- polymer consumption Capacities up to 600 Gallons Per Minute (GPM)

- Compact Design Minimizes Need for Valuable Building Square Footage

- Lower Power Requirements Versus Other Methods

- Completely Enclosed Design

- Increased Return On Invested Capital

- Design Flexibility

- Reduced Operating Costs

- Reduced Odors

- No Material Drop Off Losses

- Increased Personnel Safety During Operation

- Lower Total Cost of Ownership