JDV Equipment Corporation products

Solids Handling

JDV - Shaftless Screw Conveyor

The JDV Shaftless Screw Conveyor is a proven design to reliably transport solids with a lower total cost of ownership when compared to other transport methods. The Shaftless screw allows for a greater fill rate versus other methods/equipment, increasing operational efficiencies and lowering initial capital investment. Long life wear liners allow for increased maintenance intervals, lowering overall maintenance costs and equipment downtime.The enclosed design provides for a safe working environment for personnel while in operation. JDV Shaftless Screw Conveyors safely transport sludge, grit and screenings in thousands of Municipal and Industrial treatment plant installations.

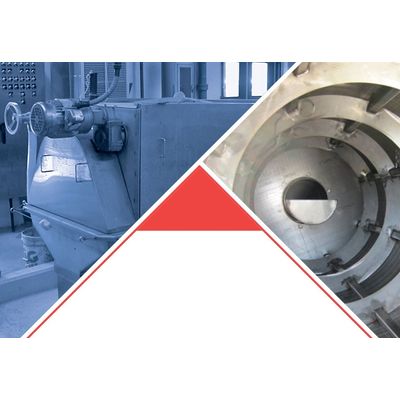

JDV - Shafted Screw Conveyor

The JDV Shafted Screw Conveyor is a proven design to reliably transport solids and is particularly well suited for dry, abrasive applications. In dry particle applications, a bed forms on the bottom of the trough to help reduce wear by eliminating metal on metal friction between the screw and trough.The Shafted screw allows for reliable transport and metering without fallback of material. The enclosed design provides for a safe working environment for personnel while in operation. JDV Screw Conveyors safely transport sludge, grit and screenings in thousands of Municipal and Industrial treatment plant installations.

JDV - Level Lodor

The JDV Level LODOR is a unique solution to solids handling and odor control. (Also available for headworks applications). The Level LODOR covers standard 20, 30, & 40 yard containers containing odors while self leveling materials. This simple solution offers lower total cost of ownership, provides operators advantages of better time management and reduced contact with process materials.

JDV - Belt Conveyors

JDV Equipment belt conveyors offer solutions for applications from municipal sludge and screened material to industrial materials. All designs meet or exceed CEMA industry standards.

JDV - Spiral Press

Dewatering of solids material processed during treatment plant operations is critical to the overall operating costs of the facility. The JDV Compactor product line offers two reliable and proven designs to dewater material with product designs focused on helping operators and maintenance personal in Municipal and Industrial treatment facilities keep initial capital costs and ongoing operating costs down.

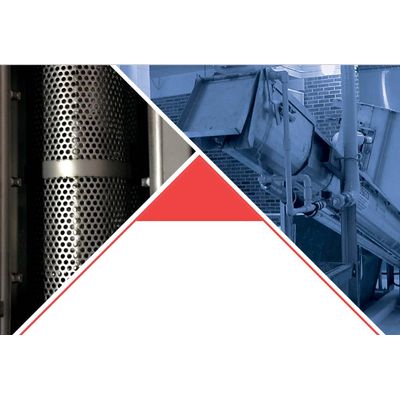

JDV - Rotary Drum Thickeners

JDV incorporated the Ralph B. Carter Company design into its growing portfolio in 1995. The drum thickener is a stainless steel design, offering a polyester filter media and direct drive system. A wide range of solids can be processed with ability of producing 5-7% TS for most applications. Rotary drum thickeners are sized to handle throughput as small as 35gpm up to 400gpm.

JDV - Water Drum Screen

The JDV Drum Screen is a proven design to reliably & efficiently separate solids with optimal throughput. The enclosed design minimizes odor and prevents solids overflow or pass through. The packaged unit also enhances safety for operators and personnel while in operation. The JDV Drum Screen has reduced capital requirements for new and retrofit installations when compared to other solutions. The JDV Drum Screen can be configured to enhance operational performance of downstream processes by "pre-treating" the influent.This removes or minimizes fouling and/or damage and increases overall plant operational efficiencies.

JDV - Step/Fine Screen

The JDV Step/Fine Screen is a proven design as a reliable self-cleaning fine bar screen for fully automated removal of solids from industrial or municipal wastewater. Removal of the non-organic solids helps increase operational plant efficiencies, particularly for downstream processing. The screen`s design results in very low head loss and is ideal for in channel applications.

JDV - Grit Washer Classifier

Small inorganic material such as sand, silt, gravel, ashes and coffee grounds are removed during the plant operations to avoid unnecessary downtime and costly maintenance/repairs associated with premature mechanical equipment failure such as pumps. These materials if not removed may also interfere with overall plant operations. This could lead to increased operating costs and allowing solids to settle out in digesters and other operations.

Anaerobic Digestion

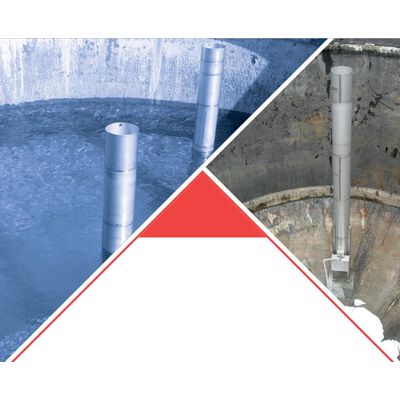

JDV - Turbomixer

JDV Turbomixer is a staple mixing design, proven to be an efficient and long lasting design to: keep digesters well mixed (bottom to top), provide reduced VSS and high gas production. These large anaerobic bubble mixers are fabricated from stainless steel. Available design options include: Heating from within digester and high quality compressor options for gas delivery.