- Home

- Companies

- BHS-Sonthofen Inc.

- Products

- BHS - Rotary Pressure Filter (RPF)

BHS - Rotary Pressure Filter (RPF)

The BHS Rotary Pressure Filter is a continuously operating unit for pressure filtration, cake washing and drying of slurries up to 50% solids.` Filtration is conducted via pressure of up to 6 bar. Positive displacement washing, reflux or counter-current washing follows filtration. Multiple washing steps as well as solvent exchanges, steaming and extraction can also be accomplished. Finally, the cake is dried by blowing hot or ambient-temperature gas through the cake. The Filter has a uniquely designed discharge system, which provides for atmospheric discharge from pressure filtration. After automatic cake discharge, the filter cloth is washed; the clean filter cloth the re-enters the feeding / filtration zone thereby continuing the process. All solvent and gas streams can be recovered separately and reused in the process to minimize their consumption.

Continuous, High-Throughput Design

Through continuous, thin-cake filtration the RPF is able to process suspensions while maintaining efficient throughputs.

Completely Enclosed

The RPF operates as a closed, gas-tight system, which helps to contain and control the process. This allows the filter to be well-suited for filtration of hazardous materials such as solvents.

Low Wear – Low Maintenance

Slow rotation means minimal wear and tear on the mechanical elements of the filters. These filters are able to operate 24-7 with only small annual maintenance.

Production of high-quality pearlescent pigments with the rotary pressure filter (RPF)

BHS-Sonthofen rotary pressure filters have proven themselves in many applications. For example, Merck uses them around the clock to produce pearlescent pigments. Watch the video to find out how BHS filtration solutions give cars and cosmetics a shiny appearance.

- Operating method: continuous

- Operating pressure: up to 6 bar (g)

- Operating temperature: up to 160° C

- Soldids content (suspension): up to 60 % (by weight)

- Cake thickness: up to 175 mm

- Grain size: 10 – 500 µm

- Filter output – suspension: up to 30 m³/m² h

- Filter output – dry solids: up to 15.000 kg/m² h

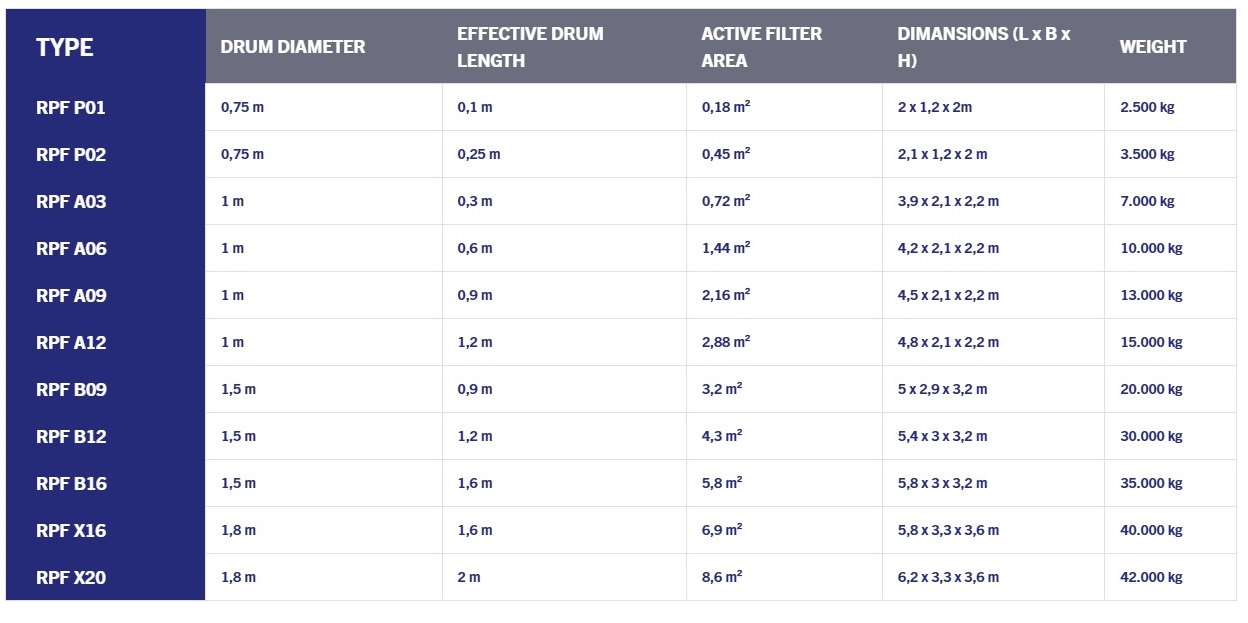

- Active filter surface: 0,18 – 8,6 m²

P01

- Active Filter Area: 0.17 m²

- Dimensions (LxWxH): 6ft x 4.5ft x 6.5 ft

- Maximum Operating Pressure: 6 barg (87 psi)

- Material of Construction: Stainless Steel