- Home

- Companies

- Saint-Gobain PAM

- Products

- Saint-Gobain-PAM - Air Inlet Check ...

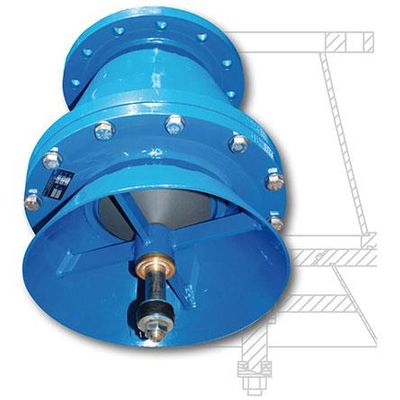

Saint-Gobain-PAM - Air Inlet Check Valve

The purpose of the Air Inlet Check Valve is to permit a high flow air intake into the pipe, in order to prevent negative pressure, the result of which would be damage to the sealing joints and a risk of the pipe being crushed. It provides a normal flow during pipe draining.

Generally speaking, the choice of the ND of the air inlet check valve is based on an admissible negative pressure in the pipe of 2 meters water column. We then apply a ratio between the air flow in L/s and the cross section of the passage of the air inlet check valve, in dcm2 equal to 1900.

This figure is constant whatever the ND for the air inlet check valve, since it is given by the maximum velocity of air input which is 1900 dcm/s, that is 190m/sec.

Compliance with standards

- The Air Inlet check valve conforms to standard EN 1074 -1 & 4.

- Minimum and maximum operating temperature: 0 to 70° C.

- Minimum sealing pressure: 0.1 bar.

- Permissible operating pressure (PFA) 10/16/25/40 bars depending on model.

- Certificate of sanitary Conformity (ACS).

Installation

- The air inlet check valve is installed in a valve chamber (see diagram) sufficiently ventilated by an upper grill cover.

- It is recommended to fit a stop valve, which allows an eventual dismantling of the appliance, without having to close down the operation of the circuit.

- It must be placed in a vertical position, at a height well above the pipe (see diagram) in order to prevent the sucking in of foreign matter into the pipe.