- Home

- Companies

- Samsco Corporation

- Products

- Samsco - Model II - Water Evaporator

Samsco - Model II -Water Evaporator

The Samsco Water Evaporator II is Samsco’s flagship product, and has set the industry standard for water evaporator design and manufacturing.

The SWE-II uses a system design that provides consistent operation, minimal cleanout, high efficiency and ease of maintenance. Specific features include:

- Redundant control/safety sensors utilizing technologies different from those of the primary sensors to avoid common-mode failures

- Integrated process control that maximizes reduction-in-volume (typically in the range of 90-99%) while providing accurate displays of operating conditions.

- Logical design incorporating a “wet” end for fluid management, a “dry” end for heat and electrical input and for controls, together with a “cold zone” for solids settling

- Three-stage mist elimination system

- Air-handling system keeping combustion products isolated from operator contact and safely contained away from personnel

- Optional condenser, modem, auto-drain, auto-overflow, etc. all under PLC control

Evaporating wastewater reduces disposal volume and recycles water.

Environmental experts agree… evaporation offers industry the simplest and most effective long-term approach to wastewater disposal cost reduction. Since the late 1980’s, SAMSCO EVAPORATORS have been a proven solution to most wastewater disposal problems. Their design provides consistent operation, minimal clean-out, high efficiency, and low maintenance.

- Disposes of water as it separates wastes—in one simple step

- Eliminates sewer discharge accountability—forever

- Handles multiple wastes and varying chemistries— simultaneously.

- Allows fully automatic operation 24/7

- Low-cost operation as little as $0.05–0.10/gallon

- Reliable operation—little attention required

- Two year warranty—the best in the industry

The SWE-II SENTRY SYSTEM stands guard as industry processes its wastewater…

THE SENTRY SYSTEM: A PLC monitors the wastewater and controls process variables encountered as waste concentrates and changes. The SENTRY maximizes reduction-in-volume while minimizing residue disposal, and all the while provides accurate display of operating conditions.

Full-Function, NEMA 4, Evaporator Control Panel: Incorporating the SAMSCO SENTRY SYSTEM, this display provides instantaneous, easily understood, operator feedback on critical operating and shutdown conditions of the equipment. Help screens guide the operator’s decisions.

Mist Elimination System: The SENTRY uses three-stages, eliminating reliance on mechanical mist pads alone and preventing fouling and plugging of the mist pad. This pad in no way impacts the burner’s operation.

Immersion Heat-Exchanger: The elevated, tubular heat exchanger allows solids to fall past the heat-transfer surface—harmlessly—to the sloped tank floor for easy residue removal. This design minimizes the impact of sludge build-up and provides a consistent and predictable evaporation rate, while minimizing maintenance issues.

Patented Air-Handling System: Removing combustion gases and water vapors, this system keeps combustion products completely isolated and safely contained. Operators can not be exposed to flue gases.

Redundant Control Design: SWE-II control logic makes use of truly redundant devices incorporating different methodologies to sense—and reliably control—the evaporator’s operating and shutdown conditions.

- System Display (NEMA 4) eye-level English messages (remaining cycle time, bath/flue temperature, etc.)

- Context-Sensitive Help screens with scripts from the SAMSCO Operation Manual provide operators the information needed to keep evaporative process boiling at peak performance.

- Dual-level Password Security—separate operator and supervisor log-ins provide tamper-proof evaporative process control while displaying key system operating data to all.

- Three-stage Mist Elimination—large freeboard, the SAMSCO’S foam-detecting (RF-Admittance-style) level sensors minimize/detect/control mist & foam in boiling waste, preventing mist eliminator flooding.

- Stainless Exterior for corrosion protection in harsh environments.

- Improved Accuracy/Reliability—new sensing package continuously displays Cycle Time & Temperatures.

- Alarm History Memory records last 100 system alarms—for review of interruption events.

- Easily accessed tank interior—large folding lid, new air intake, improved combustion port access.

- Emergency Stop Button—red “mushroom” switch for fast, safe, total-system shutdown.

- Blower-off Delay—reduces operating cost by automatically stopping blower after tank sufficiently cooled.

- Fail-safe Control—system alarms on loss of signal (broken wire, etc.).

STANDARD FEATURES…

WHAT THEY MEAN TO YOU…

- Stainless Steel Exterior Finish

Greater ambient corrosion resistance - Large, raised, NEMA 4 Control Enclosure

Greater ambient moisture tolerance - Screened, upward facing air inlet

Minimizes waste splashing - Additional headspace

Easier skimming of foaming wastes - Low bottom trough

Additional settled sludge capacity - Programmable logic controller with graphic display

User-friendly system status with convenient, eye level display - System process control

Minimizes risk of waste over-concentration - Fail-safe input

Alarms on signal loss (broken wire, etc.) - Emergency stop button (mushroom switch)

Eye-catching safety (system shutoff) - Triple-level security

Ensures safe, approved operation - Blower-off delay

Lengthens blower-motor life & cuts operating cost - Timed Auto-fill

Improves level-control & reduces pump wear - High-level alarm control

Assures longer duty cycle - Flue Temp Monitor

Gives early warning of burner de-tuning - Cycle time monitor

Reduces maintenance time - Integrated drain control

Lowers installation cost & locks out auto-fill

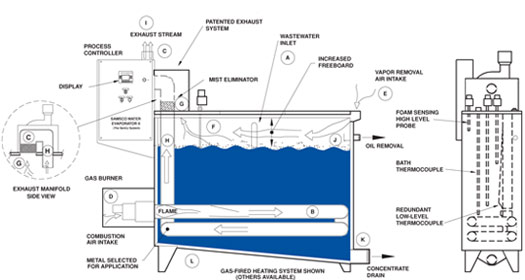

- Wastewater is fed to tank as required at (A).

- Blower (C) draws air stream into tank at (E) to remove vapors. Blower also draws combustion air into burner at (D). Heat exchanger (B) contains combustion gas, preventing its release into tank.

- Heat exchanger causes water to boil. Air moving over boiling surface (F) captures water vapor.

- Moisture-saturated air leaves tank through coalescing mist eliminator where oil/water droplets are removed and clean steam passes into manifold at (G).

- Flue gas (H) joins water vapor at blower manifold entrance—not exhausted into tank.

- Air streams—environmentally approved—are mixed in blower and exhausted through stack to atmosphere (I).

- When boiling is interrupted, oils—freed from emulsion—float to surface and are decanted at trough (J) automatically, or manually.

- Solids settle to tank’s sloping trough floor (L) and are removed with concentrated liquid through large clean-out port (K).

Metalworking:

- Acid Cleaners – Dip/Spray

- Alkaline Cleaners – High Pressure/Steam

- Coolants (Machining/Grinding)

- Die Casting Solutions

- Dye Penetrant

- Heat-Treat Quench Waters

- Lapping Compounds

- Paint Spray Booth

- Parts Washing

- Phosphatizing

- Rinse Waters

- Stamping & Drawing Compounds

- Tube Forming

- Tumbling & Vibratory Solutions

- Wire Drawing Solutions

Metal Finishing:

- Acid Cleaners

- Alkaline Cleaners

- Electroless Plating Rinses

- Electroplating Rinses

- Etching Compounds

- Ion Exchange Regenerate

- Powder Coating

- Plating Rinses

Maintenance:

- Air Compressor Condensate

- Air Scrubber Blow-Down

- Boiler Blow-Down

- Cooling Tower Waters

- Floor Scrubber Waters

- Machine Cleaning

- Steam Cleaning

Transportation:

- Engine Rebuild Cleaners & Coolants

- Floor Scrubber Waters

- Heavy Equipment Cleaning

- Pressure Wash

- Steam Cleaning

- Vehicle Wash Waters

- Waste-Oil Water Contamination

Scrap Metal Recycling:

- Oily Waters

- Steam Cleaning

- Storm Water Runoff

- Truck Washing

Printing:

- DIAZO (Blue Printing)

- Film Processing Waters

- Fixer/Developer Waste

- Fountain Wash

- Ink Vat Wash/Rinse

- Photo Process Rinses

- Ink

- Paint

- Graphite

Ultra-filter/Reverse Osmosis:

- Concentrate Stream

- Reject Concentrate Stream

Ion exchange:

- Regeneration Waste

Other Applications:

- Brine/Salt

- Chemical Vat Cleaning

- Gas-Line Waters

- Glycol (Ethylene & Propylene)

- Nuclear Waste

- Pharmaceuticals