- Home

- Companies

- San-I-Pak Pacific, Inc.

- Products

- San-I-Pak - Waste Shredder

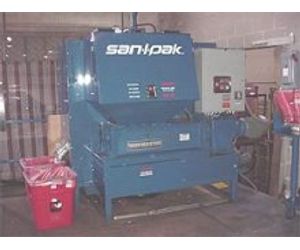

San-I-Pak - Waste Shredder

San-I-Pak has invested over one and a half million dollars in shredding research and development. We have evaluated over 60 manufacturers of shredding equipment and have worked directly with over 20 manufacturers and/or technologies of reduction equipment. Our extensive efforts have lead us to believe, we offer the best shredders for medical waste available on the market today.

Shredding is not required by San-I-Pak as part of the sterilization process. Complete sterilization throughout the waste load is achieved with every cycle in the San-I-Pak system without shredding or breaking up the waste. For those facilities that are either required to render the waste unrecognizable or feel more comfortable disposing of this type of material, San-I-Pak designs and manufactures post-treatment shredding systems.

San-I-Pak`s shredding systems shred after the sterilization process. Shredding waste prior to treatment or breaking up waste with the system door open creates the possibility of aerosolizing the microbial life contained in the waste thus endangering the operators. All shredding systems will require maintenance, and in order to perform maintenance on a pre-treatment shredding system many safety precautions must be adhered to. It is because of these liabilities that San-I-Pak encourages post-treatment shredding systems.

San-I-Pak sterilizers require no pretreatment of the waste to be processed.

Historically, the longevity of shredders is directly dependent on the severity of operating conditions due to a facility`s ability to segregate non-shreddables from the waste stream. Under optimum conditions and good segregation practices, a two-stage shredder`s cutting teeth may last as long as two years. Because San-I-Pak shredders are low speed (less than 10 RPM) and high torque, they do not self-destruct like high speed (greater than 40 RPM) particilizers and grinders.

The advent of our advanced electronic sensing system has extended the life of the cutter teeth by stopping the rotation of the blades before they break. Cutter teeth used under conventional sensing technology rarely last longer than 6 months. In order to minimize the possibility of damage to the shredder system from unshreddable material San-I-Pak has designed its systems to allow the operator to view the waste before it is introduced into the shredding system, and removes any material that will cause damage. San-I-Pak shredding system are low speed, high torque systems with electronic monitoring which will remove power to the cutter teeth in less than eight one hundredths of a second. This significantly reduces the likelihood of cutter teeth being broken by an unshreddable object.

The thicker the cutter blades of a shredding system, the shorter the processing time and the greater the volume processed per hour. Also, thicker shredder blades will reduce maintenance and decrease damage caused by the inclusion of non-shreddables into the waste stream. However, the particle size of the final product increases in size with direct correlation to the thickness of the blades. Because thicker blades are more durable, maximizing the size of the cutter blades is always a goal. In order to meet the desired particle size required by your facility, our engineers will assist you in blade selection.

Shredder Hopper Tender:

San-I-Pak has patented a Shredder Hopper Tender Non-Shreddable Clearing System that dislodges materials plugged in the hopper without the equipment operator having to risk clearing.

Sharps Machine Tray System:

San-I-Pak has designed a specially constructed sharps tray system allowing for no exposure to needle sticks while handling sharps. First sharps containers are place in the tray , tray is loaded into chamber for processing, then tray is positioned in front of sharps machine and containers are loaded into sharps hopper for shredding.

One And Two Stage Shredders:

San-I-Pak offers both single and dual stage shredders that can be sized and configured to meet unique Facility or State requirements.

Sharps Machines:

San-I-Pak manufactures two versions of the "Sharps Machine" for the destruction of sterilized sharps and their containers. The Unrecognizable Sharps Machine and Unreusable Sharps Machine both are recognized by health departments and related agencies throughout the country as a positive means of treatment and disposal of sharps.