- Home

- Companies

- Seal Master Corporation

- Products

- Seal Master - Model 101 - Inflatable ...

Seal Master - Model 101 -Inflatable Seals

Seal Master inflatable seals are fabric reinforced, fully molded, engineered rubber products that are created to provide solutions to a wide variety of applications. Like you, the engineer/designer, they are problem solvers.

To obtain the best results for your application it is important to spend a few minutes both exploring the features of Seal Master inflatable seals and defining the requirements of your application.

What follows is a brief overview of the critical factors that impact the design of Seal Master inflatable seals. This information has been arranged to provide a step-by-step overview of the performance and design of Seal Master inflatable seals and how they can meet your application requirements. If you are already familiar with inflatable seals, feel free to explore individual topics of interest. Please see navigation located on the left side of the page.

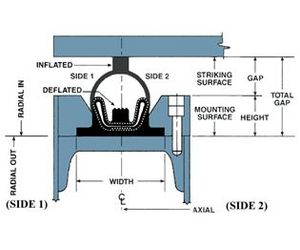

Seal Master® inflatable seals inflate and deflate in three basic directions of operation: th eaxial (or normal to the mounting plane) direction, the radial-in direction, and the radial-out direction. Each of these inflation directions has their own set of performance parameters for measurements such as the height of inflation ("stroke" of the seal) and the centerline bend radius that the seal can negotiate.

These performance parameters are further impacted by the cross-section geometry of the seal. (Seal cross-sections are presented in the section: Engineering > Cross Sectons page). To obtain an appreciation for the direction of inflation, activate the animations below by clicking on the Illustration.

Typical Inflatable Seal Configurations:

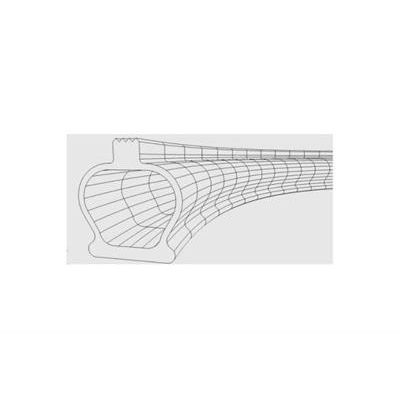

There are as many different inflatable seal configurations (or cross-sections) as the mind can imagine.

Even though Seal Master Corporation has designed and created over 7,500 uniquely different products, it could be that the configuration that fits your application has not yet been created.

The more typical inflatable seal configurations are presented by selecting the corresponding link below:

Snap-in Type

Bond-in Type

Encapsulated Type

Fasten Type

Recessed-groove Type

Drop-in Type

These configurations have been created in response to a variety of industrial, research, and military requirements. The various cross-section seal geometries each have specific performance parameters that permit them to function best in one or more of the inflation directions.

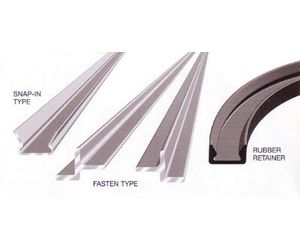

The inflatable seal profiles are further differentiated by the method by which they are retained. (A discussion of inflatable seal retention systems is provided Section 6 of this presentation.)

DESIGN NOTE!!!

These inflatable seal profiles are only a representation of some of the typical profiles used and are not representative of all of the special profiles that have been created over our 40-year history. Seal Master inflatable seals are custom engineered and manufactured for your specific application and the profile is determined by the requirements of your application.

Generally speaking, there are two major considerations that determine the seal profile for an application: geometry and environment. Consider the generic seal profile above. Each of the labeled dimensions is defined by touching the cursor to the label.

Defining the geometry of your application means describing what you intend for the seal to do mechanically in the application, and how you envision the seal`s placement in the application. In other words, we need to know how much room there is in the application to mount the seal, and how far the seal will need to "stroke" to meet the striking surface.

A sketch/drawing of your application is most helpful for Seal Master Engineers in determining the best inflatable seal approach for your application. Consider the generic seal profile above. Each of the labeled dimensions is defined by touching the cursor to the label. To determine if your application requires the seal to function in the axial, radial-in, or radial-out direction, feel free to revisit "Seal Master Inflatable Seal Basic Geometry".

Air connections for Seal Master inflatable seals are integrally molded into the seal, thus providing the greatest strength and construction integrity.

Proper installation is essential to the function and longevity of an inflatable seal. A retainer must hold the seal in place, allow it the freedom to inflate and deflate, and protect it from damage. To facilitate the installation of our inflatable seals, Seal Master can provide metal, or elastomeric retainers in strip or circular form as illustrated below.

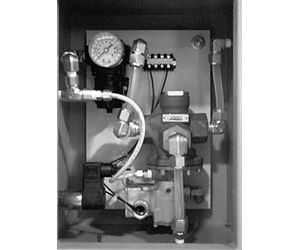

Certain process applications require that the operation of the seal be specifically controlled or cycled. In this situation, a combination of control boxes, valves, regulators, gauges, alarms, and compressors may be required. Seal Master can provide a control device should your application require it.

The control device illustrated operates an inflatable seal used in an emergency rescue vehicle.

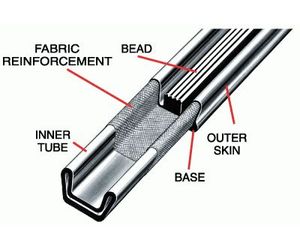

Seal Master seals are not simple rubber extrusions; they are custom built, fabric reinforced, and fully molded to fit your application. This ensures structural integrity for optimum performance.

Inflatable Seal Materials

Numerous combinations of fabric reinforcement and elastomers are utilized in Seal Master inflatable seal construction. These combinations are chosen in response to the geometric and environmental challenges of your application. You are not asked to specify materials to be used; this question is resolved through a collaborative effort between you and Seal Master engineers, as you define the performance parameters of your application.

Typical Elastomers Used in Inflatable Seals

Based on your environmental requirements, the best alternative elastomer will be selected.

Fabrics Used in Inflatable Seals

Durability and shape retention is provided by a variety of fabrics; inflatable seals are reinforced for maximum strength. Typical fabrics used to reinforce Seal Master® inflatable seals include:

Dacron

Kevlar

Nomex

Nylon