Pressure Nutsche Filters are simple and proven filtration systems for solid-liquid separation of medium-sized batches on various filter media.

In the pharmaceutical and chemical industries, pressure filters and single-layer filters are used in a large variety of forms.

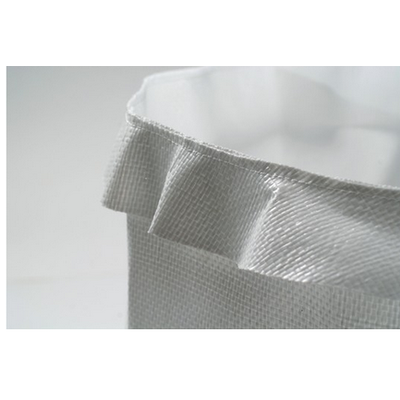

Sefar’s filter discs are characterized by their precise fit and easy installation.

The disc edges can be fabricated using laser cutting, hemmed or taped with reinforcement. In our wide range of filter materials (polypropylene, polyester, PEEK and PTFE fabric), we can supply you with the optimal solution for your application’s chemical and thermal requirements. Special bag versions are available as customized solutions.

Our products meet the specific needs of these filtration applications and are successfully running all over the world on all known nutsche filter brands and OEMs, such as:

Sefar’s Double Layer Weave technology combines fine filter fabric together with a rugged backing cloth.

SEFAR TETEX DLW fabrics are produced in our European facilities to meet the highest quality requirements and offer these decisive advantages:

- Low downtime

- High product yield

- Ease of installation

- Excellent cake release

- Minimal product contamination

In addition to DLW fabrics, monofilament and multifilament fabrics are also available to ensure an optimal design.

Sefar controls every crucial production step from yarn production to the ready-to-use filters making possible a complete traceability of all critical parts.

Our unique market position in life science enables us to supply products to our customers that meet all required quality levels and compliances.

Sefar has perfected its manufacturing processes to meet the needs of the pharmaceutical industry. Our exclusive GMP compliant filter products are manufactured in our cleanroom following strict GMP guidelines.

EC 1935/2004

- EU 10/2011

- GMP EC 2023/2006 or cGMP

- FDA CFR 177

- ISO 9001

- Single packaging

- Customized marking

- Traceability