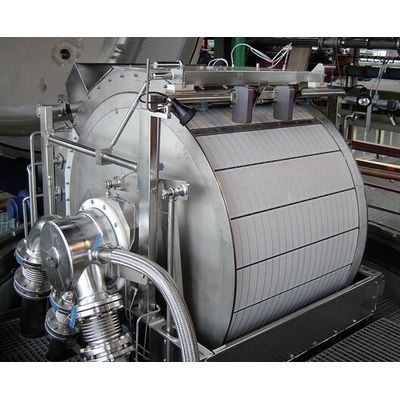

Sefar - Rotary Drum Filter Belts

Sefar’s innovative synthetic fabrics are the material of choice for rotary drum filters. Sefar filter belt and cover solutions offer excellent separation efficiency and a long, trouble-free lifetime. To cope with the demanding environment of the various process industries, Sefar has developed a dedicated range of filter media in order to maximize the customer’s value.

Understanding the filtration process is one key requirement for filter solution development. This is a Sefar core competence. We have spent decades developing filter media made from synthetic yarns.

Sefar’s innovative synthetic fabrics are the material of choice for rotary drum filters. Sefar filter belt and cover solutions offer excellent separation efficiency and a long, trouble-free lifetime.

Fitting the belts to the specific drum filter design is essential for smooth and efficient filtration performance. Sefar’s expertise helps to define the most suitable filter media and fabrication method for your utilized equipment type and application. Sefar has developed optimized custom solutions for fabric closure mechanisms and edgings for all types of vacuum drum filters.

To cope with the demanding environment of the various process industries, Sefar has developed a dedicated range of filter media in order to maximize the customer’s value.

Sefar filter media are the industries preferred solutions for rotary drum filters – trust Sefar filter belt solutions!

Chemical

Sefar products perform at high levels, even under aggressive conditions. Count on Sefar to meet the demands of your application process – whether it’s extreme pH, high temperatures, or specific chemical environments like solvents, oxidants, acids or alkalis.

Mineral

Sefar meets the high quality and productivity demands in challenging applications. Our products offer reliability in filtration by using strong woven fabrics, adapting the correct pore size to the application and providing resistance to abrasive slurries or a heavy cake.

Environment

Sefar has a solution for each application used in sludge dewatering. No matter what the characteristics of your treatment, you can trust Sefar to meet the challenges of your sludge dewatering preparation.

Life Science

Sefar production methods and facilities are integrated to include verifiable traceability for life sciences industries. Only Sefar controls the yarn production, weaving and filtration through to the final filter. The Sefar PHARMA GMP program satisfies the regulatory requirements of pharmaceutical applications.

Food

In food applications, conformity to hygienic and safety guidelines is imperative. For this reason, a reliable supplier like Sefar – able to provide you with FDA or EU compliant fabrics for filter products – is crucial to your success. You can also count on Sefar’s consistent supply of products during seasonal production peaks.