- Home

- Companies

- PURitech Gmbh

- Products

- PURItech - Model DPFN+ - Self-Cleaning ...

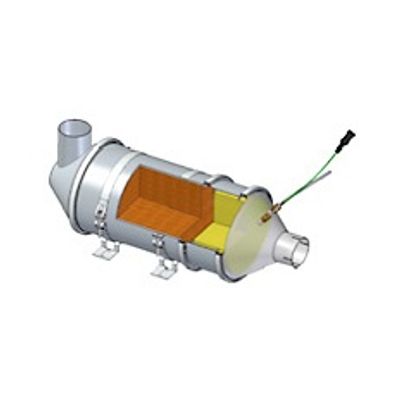

PURItech - Model DPFN+ -Self-Cleaning Standard System with Pre-Filter

This DPFN+ system by PURItech contains of an additional pre-filter. Because of that the system regenerates (self-regenerating) even at low temperatures. The DPFN+ is applicable mainly at city transportation applications. The DPFN+ system is a typical filter for metro busses and distribution vehicles.

- Permanent self-cleaning at 225C (average)

- 24 hours operating cycle without stop

- Monitoring system and system check

- Installation kit for almost all engines available

- The DPFN+ system is a self-cleaning filter system with passive regeneration on a catalyzed basis

- The DPFN+ system consists of a pre-filter

- Filter and catalyst is one unit

- The system consists of ceramic monolith

- The DPFN+ system is designed for applications with exhaust gas temperatures from 225 C and can also be used on diesel engines with medium loads

- Filter system for low backpressure, due to controlled filter regeneration

- Electronic system monitoring and data logging of operation per central unit

- Application: >20% long distance operation, >25% full load operation

- Type of Regeneration: Passive regeneration

- Regeneration Temperature: Exhaust gas temperatures from 250C

- Regeneration Time: Permanent self-cleaning during operation

- Emission Reduction:

- Particle: -99%

- Carbon oxide (CO) -95%

- Hydro Carbons (HC) – 99%

- Filter Medium : Filter monolith, Aluminum Oxide (Corderit)

- Approvals: TRGS-554 / TUEV / KBA / AUVA / VERT / CARB et al.

- Warranty: 1 Year

- Maintenance: Filter monitoring: 500 hours / filter cleaning 1000 hours

The DPFN+ system consists of ceramic monolith, sheathed with a stainless steel can and internal insulated with an elastic mat against vibrations.

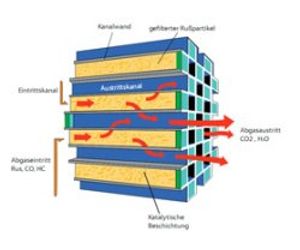

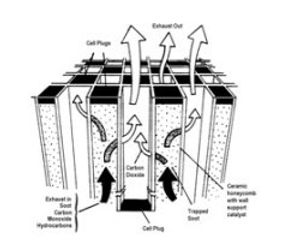

The filtration is achieved by a wall-flow method where the channels are plugged on one end and particles are remaining in the wall while the gas flows through the walls. A huge number of channels result in a big filter surface with a high storage capacity for soot particle.

The regeneration process of the DPFN+ system converts soot into carbon dioxide (CO2) and water. A residue of burned oil (ash) remains in the filter.

- Monolithic filter block made of Aluminum Oxide

- Honeycomb with reciprocally closed channels

- Channel wall with porous structure

- Exhaust gas flows through channel wall and gets filtered

- Surface of the channels are catalyzed

Long Distance Traffic

- Long Distance traffic with light load or the load is unknown

Regional Distribution

- Regional distribution with partial city transportation

City Transportation

- Less stop-and-go part

- Less idling or traffic

- Drive most of the time with load

Construction Application

- Construction application with high engine load and short idle time

Exhaust gas temperature of the vehicle:

Medium

- 230 C medium exhaust gas temperature AND

- 250C Exhaust gas temperature

- 30% duty cycle AND

- 300 C Exhaust gas temperature AND

- 20% duty cycle AND

- 320 C Exhaust gas temperature

- 10% duty cycle

The DPFN+ system doesn’t work at short distances / city transportation applications with high stop-and-go parts and long idling times.