PURitech Gmbh

- Home

- Companies

- PURitech Gmbh

- Products

- PURItech - Model DAS-DBS Type A & Type ...

PURItech - Model DAS-DBS Type A & Type B -Self-Cleaning System without Downtime with Active and Passive Regeneration

FromPURitech Gmbh

This system, developed by PURItech, combines an active regeneration (external fuel injection) and a passive regeneration (catalyzed filter or fuel born additive). The filter regeneration is automatically controlled during operation. DAS-DBS Type A and B are designed for application with low load.

Most popular related searches

diesel emissions gas

diesel fuel level sensor

filter cleaning system

self-cleaning filter

diesel emissions

particle filter

soot particle

filter cleaning

gas mixture

crane operation

- Permanent self-cleaning from 180 C (only 5% of duty cycle)

- 24 hours operating cycle without downtime

- Low backpressure optimal for stage-3 engines

- Automatically controlled regeneration during operation

- Filter heating with diesel fuel injection (+300)

- Installation kit as a replacement for muffler

- Self-cleaning filter system without downtime, ideal system for continuous use / multi shift operation

- Combined filter system for vehicles with low load / low exhaust gas temperature (stop-and-go operation/city transportation)

- Combination of active (diesel fuel injection) and passive (fuel born additive) filter regeneration

- Fast filter regeneration, only a few minutes (full loaded filter)

- Easy installation; the system can be retrofitted on every vehicle (muffler replacement)

- Operation: Diesel fuel injection less than 1% active to the total operation, no diesel fuel penalty measureable

- Filter operation without high backpressure because of controlled filter regeneration

- Filter regeneration possible from 180 C (diesel injection activation)

- Electronically monitoring and data storage via data-logger

- Application : Low load / low exhaust gas temperature

- Type of Regeneration : Combined regeneration active + passive

- Regeneration Temperature : 180 C

- Regeneration Time : Permanent self-cleaning during operation Diesel injection to increase exhaust gas temperature (+300)

- Emission Reduction :

- Particle: -99%

- Carbon oxide (CO) -95%

- Hydro Carbons (HC) -99%

- Filter Medium : Filter monolith, Silicon Carbide (SiC)

- Approvals : TRGS / TUEV / KBA / AUVA / VERT + CARB (in process)

- Warranty : 1 Year

- Maintenance : Filter monitoring: 500 hours / filter cleaning 1000 hours

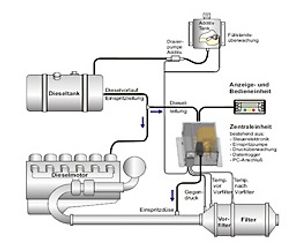

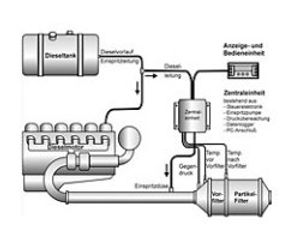

Schematic:

- Soot oxidation with fuel born additive content in diesel fuel (w/o diesel injection).

- Increase of exhaust gas temperature with additional diesel injection.

- Oxidation of the injected diesel within the pre-filter increases the exhaust gas temperature before the particle filter.

- Automatically activated diesel injection (controlled active regeneration).

- Times for diesel injection are automatically controlled by temperature before / temperature after pre-filter.

Fuel Born Additive dosing:

- Additive is added via dosing pump and return line into the diesel tank.

- Additive will be added after each diesel refuel.

- A diesel fuel level sensor calculates the right amount of additional additive.

- A float switch monitors additive level. If level is low an alarm is shown at a display/control unit.

- Dosing rate is adjustable on the display/control unit. Additive usage are stored within the electronic unit and shown at the display and control unit.

- Soot oxidation are initiated by the catalyzed filter (w/o diesel injection).

- Increase of exhaust gas temperature with additional diesel injection.

- Oxidation of the injected diesel within the pre-filter increases the exhaust gas temperature before the particle filter.

- Automatically activated diesel injection (controlled active regeneration).

- Dosing rate is adjustable on the display/control unit. Additive usage are stored within the electronic unit and shown at the display and control unit.

1. At medium/high exhaust gas temperatures (approx. >280C)

- Passive filter regeneration through catalyzed filter

- Soot oxidation on filter surface through catalytic reaction

- Low filter loading with soot particles

- Low backpressure increase

2. At low exhaust gas temperature (approx. <280C)

- Loading of the filter with soot particles

- Increase of backpressure

- Automatically activation of diesel injection

- Exhaust gas temperature increase from 180 C up to i.e. 450 C

- Fast soot oxidation on filter surface through catalytic reaction

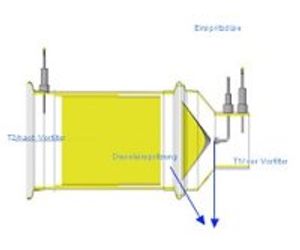

- Diesel fuel is injected by the injection pump / nozzle into the exhaust gas stream.

- Diesel-exhaust gas-mixture flows through the pre-filter and oxidizes, conversion from chemical energy of the diesel fuel into heat energy, which increases the exhaust gas temperature.

- Increase of exhaust gas temperature is time controlled by the diesel injection.

- Diesel injection will be initiated if a maximum allowed backpressure before the filter is reached.

- Injection time is controlled by two temperature sensors (T1: before pre-filter / T2: after pre-filter)

Engines and vehicles with low load and low exhaust gas temperature

- Forklifts

- Vehicles with engine-stage 3

- Vehicles with crane operation

- From 180 C