Toro Equipment S.L.

- Home

- Companies

- Toro Equipment S.L.

- Products

- Draco - Model FPSA - Semi-Automatic ...

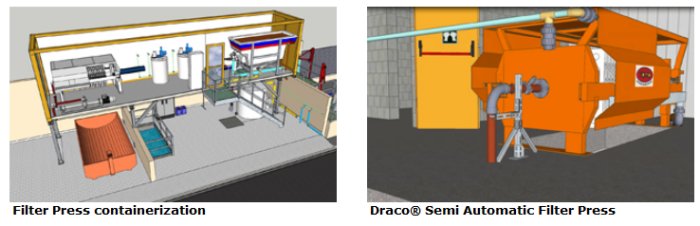

Draco - Model FPSA -Semi-Automatic Filter Press

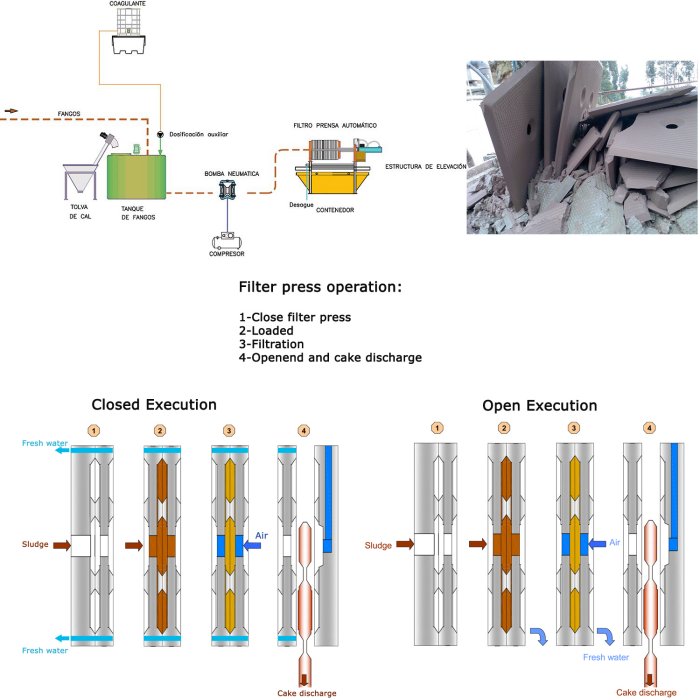

Requires operator action for motorised opening and closing of plates. Maximum filtering surface: 1.5m² at 64.3m². Maximum number of plates: from 5 to 60. Plate size: from 470mm to 800mm.

Most popular related searches

semi-automatic filter press

automatic filter press

filter press

automatic polyelectrolyte plant

sludge conditioning tank

sludge conditioning

filter plate

sludge management

high capacity drainage

boring machine

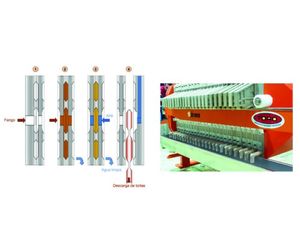

Open execution

- Override option with the installation of different taps.

- Allows easy inspection of the quality of the filtered liquid.

- Allows quick location of damaged/broken fabric.

- Suitable for preventing the drained water from coming into contact with the outside to protect it from contamination.

- Ideal for working with hazardous products.

- It also allows the cleaning of fabrics and the blowing of cakes.

- The range of filter press consists of five different models

- Extend the life of your equipment with materials manufactured using environmentally friendly processes.

- All machines, regardless of model and size, are characterised by:

- Manufactured in stainless steel St 37-2, AISI 304 and GRP.

- Epoxy paint surface finish to protect them from possible corrosion.

- Draco® Filter Presses achieve greater dryness, reducing the cost of managing the sludge generated.

- Easily transportable sludge. Problems such as liquid overflow in the containers are avoided.

- Sludge can be stacked once dewatered. The high degree of dryness facilitates sludge management, composting and logistics.

- Total reliability 24 hours a day. Unattended operation thanks to the cake shaking system.

- Low process water consumption.

- Minimal maintenance costs.

- No need for greasing.

- 100% automated cycle operation.

- Precise control of actual sludge production.

- Fairings that favour more hygienic atmospheres than rotating systems.

- The sludge only comes into contact with the air at the moment of opening.

- Possibility to filter sludge directly from the biological reactor without thickeners.

- Filtration below 10 μ.

- Guaranteed flow rate in cycles longer than 24 hours.

- Low investment and high reliability.

- High drainage capacity filter press.

- Fast cycles.

- Robust operation.

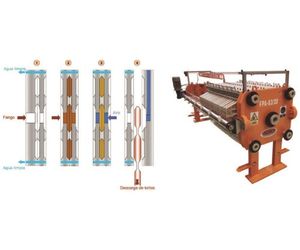

- Closed execution. The material does not come into contact with the chassis.

- Chassis in stainless steel or GRP infused in isophthalic resin or vinylester with high structural and corrosion resistance.

- Special filter plates.

Fabrics

In order to obtain the maximum performance of the equipment, each filter press incorporates the most suitable filter cloth for each specific application:

- Standard fabrics.

- Fabrics with anti-drip frame.

- Fabrics for watertight plates.

- Special fabrics for the treatment of aggregates.

- Fabrics for other specific treatments.

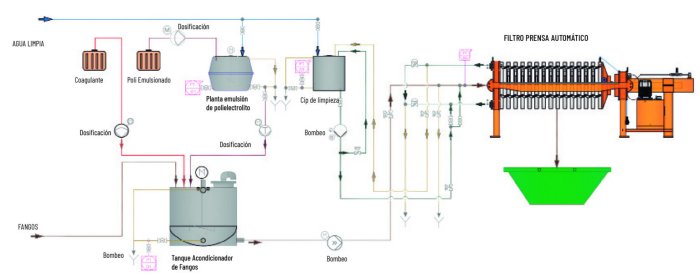

- Automatic polyelectrolyte plant

- Sludge conditioning tank

- Flocculator

- Soda dosing machine

- Polyelectrolyte dispenser

- Firefighter sludge to filter press

- Wastewater

- Wastewater for reuse

- Stone

- Aggregates

- Tunnel boring machines

- Antibiotics

- Food

- Drinks

- Chemicals

On request:

- Transportation of equipment in treated wooden crates.

- Palletising and plastification of equipment.

- Containerisation.

NOTE:

(1) The Semi Automatic Filter Press FPSA Draco® is supplied with:

- Side protection plates.

- Filtered water collection channel and handles.

- Compressed air socket.

- Equipped with circuit-blowing cakes.

- Hydraulic oil included.

(2) Compressor not included.

(3) The dimensions and specifications may vary slightly due to the normal development of products by the engineering department or Toro Equipment SL.