- Home

- Companies

- Disab Vacuum Technology

- Products

- Disab Vacturion - Model TD5RR - ...

Disab Vacturion - Model TD5RR -Semi-Mobile Diesel Powered Vacloader

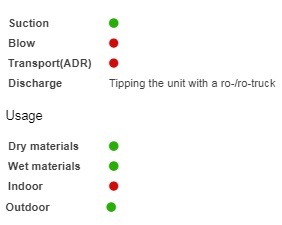

This is a semi-mobile, diesel powered vacloader mounted onto a roll-on/roll-off frame. Its flexible discharging feature makes it particularly suitable for handling dry materials and collecting bulky or fibrous/sticky materials. Limited add-ons available.

The TD5RR suction unit meets the industry’s high demands on efficiency, reliability, ease of operation and maintenance giving excellent value for money.

The VACTURION TD5RR units are complete self-supported diesel powered vacuum loaders mounted onto a ro-/ro-frame. Dry material can be handled. In combina tion with a fixed pipe network they can either operate as central vacuum units for industrial applications or as independent vacuum loaders with a 6” hose.

- Rigid design for industrial use

- Vacuum pump of the Roots-type with high vacuum(80%)

- Filter system for dry and wet material

- Automatic cleaning without compressed air

- Donkey engine power ranging from 129 kW to 180 kW

- Large dust collecting hopper

- Low noise level

Heavy industry sites often have production, raw material handling, packing etc. in several buildings /domestic areas. Therefore an ordinary stationary central vacuum cleaning system is not the optimum solution. Further more, cleaning contractors need flexible and powerful vacuum units to meet customers requirements for cost- efficiency. This is why the TD5RR is the perfect choice. The large collecting hopper placed on a ro-/ro-frame for the handling by truck makes the whole unit easy to handle. The unit can start operating as soon a pipe/hose is connected. Discharging sucked material is easily managed by tipping the body with a ro-/ro-truck.

The large load volume in combination with the high suction capacity provided by the Roots pump, makes the TD5RR especially suited for heavy industrial environments.

The vacuumed material is first separated in a special designed fall chamber with a durable proof pre-separator inlet. Here heavy particles fall to the bottom of the container. The air is diverted to the main filter section where remaining fine dust is separated. From the filter section the air passes a safety filter before entering the vacuum pump and finally a silencer before exhaust. The well insulated motor compartment housing ensures a low noise level of the unit.

An unloading valve is placed between he main filter system and the vacuum pump. The vacuum is immediately equalised when the valve opens. At the same time the main filters are being cleaned. This also prevents counter-rotation of the engine as well as less power consumption at starting. It can also be activated by safety control functions. All functions are operated from the dust-tight control panel which contains control lamps indicating operational status of the unit.

For any application where collection of dust is required, i.e. cleaning out deep pits, trenches, bucket elevators, conveyor spills, overhead cranes and runaways, dust collectors, processing machine spillage, and vacuum excavating.

The unit is particularly suitable for collecting bulky or sticky material thanks to the convenient discharging.

- Our units provides better environment, servicing manufacturers of Cement, Lime, Gypsum, Tiels, Ceram- ics, Fertilizers and Alumina.

- Foundries, Steel mills, Quarries, Mines, Pulp- and Paper Industry, Incineration Plants, Thermo-electric Power Plants, Cleaning Contractors....

- Vacuum pump: three-lobe rotary pump

- Max vacuum, mbar: 800

- Max overpressure, mbar: N/A

- Air volume m3/h (unloaded): 4600

- Operation speed (rpm):

- Power: 129

- Voltage Frequency, V/Hz: N/A

- Tank volume (m3)*: 4,3

- Total tank volume: m3

- Power source: Diesel

- Engine type: 4/3

- Tank material:

- Tank tipping: Tailgate is hydraulically operated and locked.

- Main filter system (m2): 40

- Safety filter surface(m2): 36

- Cooling air:

- Atex: On request

Weight and Dimensions**

- Complete unit (including chassis): 8 800 / 9 200kg

- Total unit length including tuck chassis: 6 400mm

- Total width: 2 500mm

- Height (incl. hose boom): 2 600mm