- Home

- Companies

- Ecoprocess Engineering Limited

- Products

- Panther - Sewage Treatment Plant

Panther - Sewage Treatment Plant

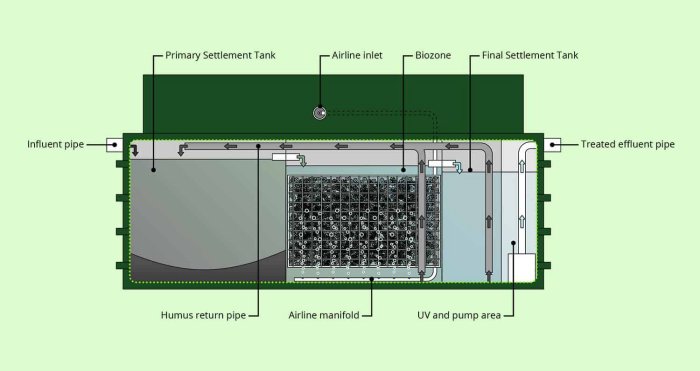

The Panther is a low capital cost wastewater treatment plant, incorporating an extremely robust natural process. The plant is straightforward to install and service. It utilises advanced self-regulating aeration flow technology, enabling variable flows and loads to be processed efficiently. The processed water meets UK/Caribbean regulatory authorities’ water efficiency standards and guidelines for all green building certiï¬ÂÂÂcation programs. Integral ultraviolet (UV) disinfection further treats the water to remove 99.99% of pathogens. The Panther will provide a long-term solution to your wastewater needs with the added benefit of complete peace of mind when using our remote monitoring.

- robust three-stage natural biological process

- advanced aeration flow technology

- bespoke design using twin pipe re-circulation

- custom built for flow and loading

- compact footprint with minimal visual impact

- advanced remote monitoring

- integral discharge pumps (as required) and UV (no separate chamber)

- no complex mechanical or electrical components within the unit

- Advanced aeration technology

- Bespoke design/sizing

- Self-regulating return pipe

- Low flow and load capability

- Robust natural process

- Underground option

- Low blower power rating

- No complex moving parts

- Plug and play set up

- No specialist staff needed

- Minimal spares list

- Easily maintained

- Reuse of treated water

- no noise, no odours

- reduced installation costs

- long maintenance intervals (and minimal servicing)

- eco-friendly, no hazardous chemicals

- zero and variable flow (seasonal fluctuations) easily accommodated

- Efficient processing of effluent

- Lower footprint / Lower civil engineering cost

- Can deal with low and no flow conditions

- Highly fluctuating usage patterns accommodated

- Noise and odour free, no chemicals required

- Low aesthetic impact / hurricane resistant

- Reduced running cost

- High reliability and longevity of plant

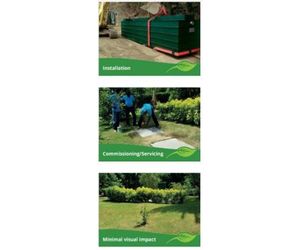

- Easy installation and commissioning

- Low operational complexity and cost

- Speed of repair and low downtime

- No specialist technician required

- Typical ROI 2-5 years

The performance, reliability and simplicity of maintenance of the Panther make it the obvious choice for diverse applications, whether island or mainland, rural or urban.

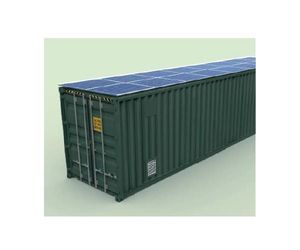

Ecoprocess Engineering Limited provides a full design, manufacture and supply service of the Panther wastewater treatment plant with the optional Lynx range of pumps, grease management and off-grid solar power solutions – offering you:

- No fee initial consultation

- Detailed site survey and analysis

- Highly effective and proven technology

- Durable and easily maintained plant

- Comprehensive warranty and after sales support

The effluent treatment performance together with the lack of complex moving parts mean that the Panther is ideally suited for installations where outflow quality, durable operation and ease of long-term maintenance are paramount – whether mainland or island, urban or rural. Typical applications include:

- Hotels and golf courses

- Resorts and villas

- Private islands

- Small communities

The Panther utilises proven technology and a robust natural process which, coupled with advanced self-regulating aeration technology, permits variable flows and loads to be treated efficiently. The three-stage plant can be buried or ground mounted, incorporating: primary settlement, biological treatment and final settlement. The Panther is extremely efficient and uses less than 10% of the energy required for a conventional activated sludge treatment plant with a typical ROI of 2-5 years. The Lynx range of complimentary products gives the complete sewerage solution where a bespoke decentralized plant is desirable.

The Panther process is designed in accordance with the requirements of BS 6297 and certified to BSEN12566 – Pt3. It produces an effluent quality suitable for irrigation with an output of 20mg/L B.O.D.: 30mg/L Suspended solids: 20mg/L NH4 or better where specified.

- ‘Off-grid’ solar option

- UV disinfection

- Pumped discharge

- Grease traps

- Remote telemetry monitoring