- Home

- Companies

- Sgorbati Group Srl

- Products

- Sgorbati - Potatoes Calibration and ...

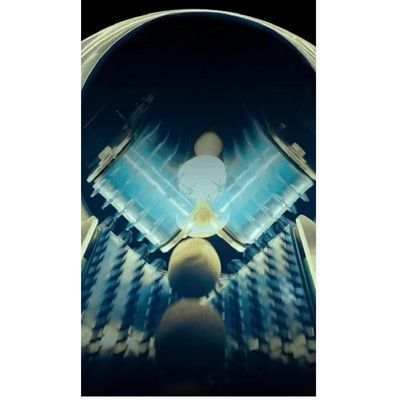

Sgorbati - Potatoes Calibration and Optical Sorting Machine

Whatever the final goal of our work, fresh or for processed, potatoes need to be calibrated for several reasons: to optimize production processes, to reduce waste, and to provide the consumer with more homogeneous final products. For grading, the most used machine is the potatoes net grader which, thanks to successive sieves, with different sizes of the net, obtains a dimensional separation of the same. Less used, because it is fundamentally linked to the world of carrots, is the roller sizer.

The novelty is represented by the electronic calibration which allows, through a camera, the analysis of qualitative, as well as dimensional parameters, and the classification of the potatoes according to the overlapping of these same parameters.

Analyzing their needs together with its customers, Sgorbati Group identifies the most suitable potato grader to carry out the job in the most efficient and effective way.

It is good to remember that food safety regulations are being tightened more every day and consumers are becoming more and more demanding. The presence of extraneous materials or low quality products is not just a matter of food safety: in times of increasing competition, quality problems can be downright damaging to your reputation.

You want to be able to get as much as possible out of 100 tons of potatoes, but at the same time you also want to satisfy your customers and the customers of your customers, the consumers.

In short, it is important to optimize the selection process; detect as many extraneous materials and defects as possible and without unnecessarily removing good products.

The solution to do all this is the potatoes optical sorter.