- Home

- Companies

- ASM Assembly Systems GmbH & Co. KG

- Products

- SIPLACE - Model CA - Placement Modules

SIPLACE - Model CA -Placement Modules

Chip assembly and SMT placement in a single machine. Integrate high-growth technologies of the future such as flip chips and die attach into your SMT production with the SIPLACE CA, the world’s first platform that lets you flexibly combine the placement of bare dies directly from the wafer with classic feeder-based SMT placement. Your competitive advantage: New, future-proof applications can be implemented on a single SMT line without any additional special processes. It is the ideal machine for “Advanced Packaging” applications. Another benefit: For all other jobs, the SIPLACE CA operates as a powerful “normal” SMT placement machine.

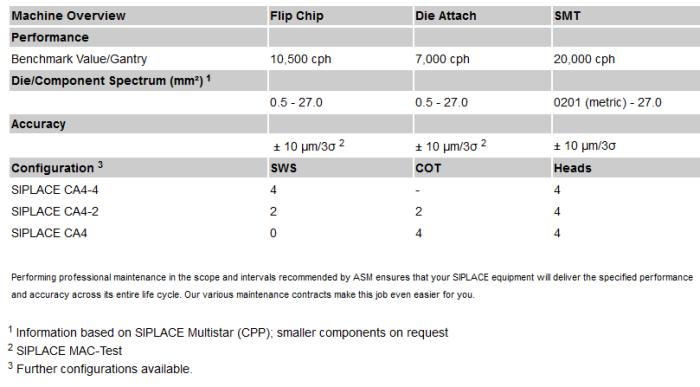

The SIPLACE CA places up to 42.000 flip-chips or attaches up to 28.000 dies per hour with four of its SIPLACE SpeedStar heads. The components are supplied via special SIPLACE wafer systems (SWS) directly from wafers with diameters ranging from 4 to 12 inches. A Flip-Chip Unit (FCU), Die-Attach Unit (DAU) and Linear Dipping Unit (LDU) complete the equipment of the SIPLACE CA for flexible and highly accurate bare-die placement applications (+/ - 10 µm @ 3σ with embedded Wafer Level Ball Grid Array (eWLB) - Option).

The gantries and heads of the SIPLACE CA which are not being used for bare-die placement can be supplied via component carts and X-feeders with passive components for the classic SMT placement process at speeds of up to 80,000 cph per head.

In short: The SIPLACE CA is the perfect solution for your state-of-the-art electronics production. Chip assembly and classic SMT placement converge on this platform for the first time.

Chip assembly and SMT placement on a single platform

In the die-attach or flip-chip process, the SIPLACE CA places bare dies directly off the wafer. But it also offers the SMT placement features you already know from the SIPLACE X-Series. The SIPLACE CA can be used for bare-die or SMT placement exclusively or handle both in a single-pass operation.

No compromises in terms of speed and accuracy

Up to 28,000 dies, 42,000 flip-chips or 80,000 SMT components per hour – specifications that speak for themselves. A special vision system enables the SIPLACE CA to place bare dies in sizes ranging from 0.5 to 27.0 mm with an accuracy of ±10 µm @ 3 σ with eWLB option. For SMT placement, the SIPLACE CA is fully 0201 (metric)-capable.

Everything you need for die assembly

Many special developments optimize the deployment options for the SIPLACE CA. The horizontal SIPLACE wafer system is suitable for wafers ranging from 4 to 12 inches and changes wafers automatically. Multi-die capabilities, programmable die cutting speed and hoop ring handling are additional features. The Linear Dip Unit, Die Attach Unit and Flip Chip Unit complete the SIPLACE CA and the placement platform for bare-dies.

Beyond SMT: WLFO and embedded PCBs

New technologies like wafer-level fan-out or embedded PCBs enable even higher packaging densities, more I/Os and lower costs in component manufacturing. The SIPLACE CA provides a precise and high-throughput solution for high-volume environments. It places active dies, flip chips and the smallest passive components with an accuracy rating of 10 µm @ 3 sigma and extremely high speed onto large panels – performance values that are out of reach for classic die bonders.