- Home

- Companies

- SolarTiger GmbH

- Products

- SolarTiger - Sewage Sludge Drying ...

SolarTiger - Sewage Sludge Drying Technology

SolarTiger stands for innovative and sustainable drying technology, using natural resources. Under the brand name of SolarTiger all components for the construction of a solar drying plant are launched. Thereby the components offered components range from automation of the solar drying, via dewatering of sludge, right through to the classical components for solar drying. The close alignment of the work on location and the production of precast parts as well as the coordination between the drying hall and the machine technique for sewage sludge drying allows to use synergies spanning disciplines in an optimal way. The brand SolarTiger does not only concentrate on solar drying. It also busies with the tasks beyond.

The SolarTiger technology stands for efficient solar drying of sewage sludge and bulk materials.

The strong point of the SolarTiger® technology is the mass reduction through the evaporation of water with minimum energy use. This way sewage sludge becomes a sustainable raw material for energy production.

Thanks to the innovative hexagonal rotating drum the SolarTiger® technology combines different important functions of solar drying with minimum use of electric energy.

- Turning the sewage sludge in order to always have wet material on the surface

- Aeration to hold the sewage sludge aerobic and to avoid unpleasant odours

- To transport the sewage sludge along the longitudinal axis of the drying hall

- Distribution of the sewage sludge after its input to the drying hall.

With the SolarTiger® technology also external sources of heat can be used to increase the dry matter content at the end of the drying process.

If the SolarTiger® technology is applied to dry very odour-intensive sludges, we offer the possibilities to use our SolarTiger® -AO method or to install air treatment.

In the SolarTiger® technology a hexagonal rotating drum ensures an evenly granulated dry product as well as sufficient aeration of the drying material.

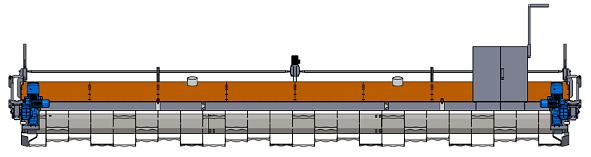

The height adjustable, rotating drum is mounted on a frame and aerates the sludge during the drying process with paddles which are fixed on the hexagonal drum-shaft.

This crane-like frame runs longitudinal through the hall. The immersion depth of the drum in the sludge can be adjusted continuously.

Due to the innovative hexagonal shape of the drum, the solar drying gets even more energy-efficient.

- The idle power demand is reduced considerably.

- The drum is balanced at the best. This way the possible area output and the processed sludge amout can be increased significantly at the same level of motorization.

- Due to the gains in area output, the aeration is intensified. Thereby unpleasant odours can be prevented even more effectively.

The operation of the SolarTiger® technology is very simple and works essentially automatically. Personnel costs can be kept very low and there are no technical skills required to operate the solar drying.

The drum is operated via touch panel on the switchboard.

Depending on customer requests the delivery is adapted to the application and the drying material.

Usually, sewage sludge is not disposed directly at the WWTP. More often the dewatered sewage sludge is transported to the utilization with a water content of 70-80%.

Your benefits with the SolarTiger technology:

- Costs for disposal are reduced and stabilized.

- The volume and therefore mass of sewage sludge is reduced by 3/4.

- The SolarTiger technology requires only little electrical energy.

- The dry granule which is formend with the SolarTiger technology has a high storage stability and does not arise unpleasant odours.

Solar drying with the SolarTiger technology is the clever extension of the waste water treatment process.

For the application of the SolarTiger technology to very odour intensive sludges it is possible to install a downstream air treatment. This two-step procedure utilises biological and chemical processes to avoid the output of unpleasant odours.

The system consists of an exhaust air scrubber and a biological filter. During operation dust, ammonia and other nasty odours are removed from the exhaust air.