- Home

- Companies

- SkimOil, LLC

- Products

- Solvent-Free Aqueous Parts Cleaning ...

Solvent-Free Aqueous Parts Cleaning Systems

Blast away dirt, grease and grime in just minutes! Washing parts can be TIME AND LABOR intensive. An aqueous parts washer cleans while the skilled employees stay productive. This increases your productivity and profitability. Simply load the parts, close the door, set the timer and the parts are cleaned automatically. Money is also saved by reduced hauling costs, insurance and the potential fines associated with hazardous chemical spills.

An aqueous parts washer pays for itself in less than 1 year.

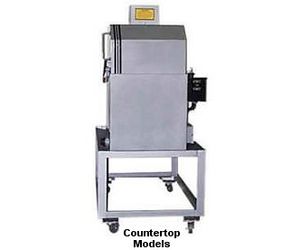

Models 35 and 50 can replace solvent washers in any environment. Both units are large enough to clean small parts for cleanroom preparation as well as automotive heads, manifolds, transmissions, and other parts of comparable size. Send your parts to us for in-house cleaning and testing.

When the wash water becomes contaminated with solder flux, grit, oil, paint, dirt and grease so that it no longer cleans efficiently, the Hydro-Blast™ Wastewater Evaporation System is initiated with the flip of two switches. Wastewater is reduced by 98% and evaporated from the parts washer over night. No more sewer discharge and liabilities or volume commercial waste hauling.

Models 80, 100 and 100-Tall, can replace solvent washers in any environment, and will clean small parts for cleanroom prep with multiple turntables and baskets and parts like automotive engine blocks and other comparable sized parts. The Model 100 is perfect for diesel engines and other heavy duty, large jobs. There a re several options available. External filters, fresh water rinses, air knives and blowers plus other options are available. The Model 100T has additional height capacity for tall loads.

All units are available in powder coated mild or stainless steel with electric, propane or natural gas heat sources. Standard equipment includes an oil skimmer and wastewater evaporation system. There are several standard and custom sizes to choose from. The top door on Models 50 and larger facilitates easy loading with a crane or fork lift. Models 80 and larger have a vent fan. Longevity of the drive mechanism is assured because it is located outside of the wetted environment. There are no front door gaskets to leak or wear out. The small footprint allows placement of a large capacity washer in a limited space. Send your parts to us for in-house cleaning and testing.

Models 175 and 200 are for your largest cleaning jobs. The model 200 is the largest standard unit that Hydro-Blast, Inc. manufactures. The model 200 has double doors for easy loading as well as a top door to facilitate a chain hoist or fork lift for hanging heavy parts. Larger, custom units are available.

Model 300 Model 300 and custom units can be built to meet your size requirements, weight loads and cleaning needs. Many more options are available.

Wastewater Evaporation Disposal All Hydro-Blast units come with this built-in feature that will reduce your sewer accountability, commercial waste hauling fees and on-site storage costs.

Save Time and Money Aqueous Parts Washers are labor and time savers. Because they clean automatically, your skilled employees can work on other productive, revenue generating tasks. The payback of a unit in labor savings alone usually is within 6 to 12 months.

Zero Degree Spray Orifices All cabinet style Hydro-Blast units have zero degree high impact spray orifices not fan nozzles. They maintain 70% of their original spray impact at 8 inches versus a fan nozzle which has only 5% of its impact pressure at 8 inches. Pencil jets are easy to clean if clogged and won`t break or need replacement.

Front Load with Top Door and no mechanical seals Units are easy to load from the front and a top door opens for parts that are too heavy to manually lift. There are no mechanical seals to wear out, leak and replace.

High Quality Parts and Motors All units are built with high quality, brand name components such as Allen-Bradley, Wayne, Bussman, Baldor, etc. The Goulds stainless steel pump are corrosion resistant and can handle high levels of suspended solids.

Top Drive Mechanism The motor that rotates the turntable is belt driven and located outside of the wash environment. If a part shifts and jams inside the cabinet, the belt will slip and not cause motor damage. All turntable drive components are located above the unit and outside of the wash cabinet.

Powder Coated Units All units are industrial quality, built of mild or stainless steel and powder coated with environmentally responsible epoxy resins. Powder coating is baked on at 400 deg. Fahrenheit for a durable, corrosive and scratch resistant, finish.

Natural Gas, Propane, or Electric These heat source options allow you to have the most cost efficient unit for your location and cleaning needs.