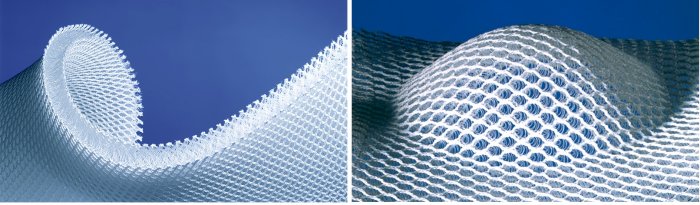

3 mesh - Model 6-20mm -Spacer Fabric

Soft cushioning and air permeability for high functionality. In the case of ductile cushions security and reliance play crucial roles. Only if the material adapts to the body perfectly, humans feel wholly comfortable. For ventilated seats in the automotive industry, stability and air permeability are key. The following things are therefore especially important for 3mesh spacer fabric of 6-20 mm: The soft cushioning, the high shock absorption, the stability and the air permeability. Soft cushioning effects, high shock absorption and the excellent recovery make 3mesh spacer fabric by Müller Textil the ideal material for mattresses and furniture. In addition 3mesh convinces in automobiles and in the safety industry owing to many qualities like the perfect honeycomb structure.

3mesh: for every application

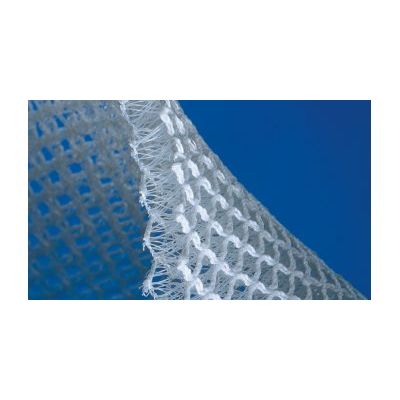

Whether laser or mechanically cut, whether covered or coated commodity: The outstanding characteristics of 3mesh spacer fabric permits highest efficiency and precision in production. Thus Müller Textil guarantees optimal functionality for every use, requirement and industry.

Our technology allows us to vary the construction of the two outer layers and the pile yarn independently. Therefore it is possible to adjust the hardness and the spring characteristics. In this way we can develop a 3mesh spacer fabric to suit every application perfectly.

3mesh offers you:

- Extremely high air distribution in all directions – even under pressure

- Soft cushioning effect

- Excellent recovery

- High shock absorption

- Very low weight

- Enormous forming property and contour flow

- Recyclability

- Öko Tex Standard 100

- Long product life

- Comfort surface feel

- Good lamination qualities

Large product variety

3mesh spacer fabric is available:

- On roll (Large choice from 20 - 500 m)

- Punched shaped parts (Custom-made for every application)

- Laminated goods (For leathers, cloths and numerous cover materials)

- Mechanically cut goods (Economical production of complex contours)

- Laser-cut goods (Highest precision for custom-made manufacturing)

- Special finishings (Increased functionality for nanotechnology and Smart Textiles)