- Home

- Companies

- Toro Equipment S.L.

- Products

- Defender - Model TR-Smart - Stainless ...

Defender - Model TR-Smart -Stainless Steel Rotary Screens

We have developed an optional intelligent program for our machines. It is equipped with a frequency inverter specifically designed for the motor, which guarantees low energy consumption. It operates as a stand-alone machine that does not require any configuration or parameterization, just plug and play. The TR-Smart integrates a data logger based on historical values, which calculates the optimal starting speed in any application, avoiding overflow and the frequency converter adjusts the screen speed automatically.

In addition, it measures the amount of dirt accumulated on the equipment and decides when to start the cleaning cycle.

Defender brand rotary screens: high performance filters for solid-liquid separation. Perfect for pretreatment of wastewater. Produced entirely by Toro Equipment SL.

TR Defender 40 and 63 Ranges, with filtering capacity five times higher than a static screen.

TR Defender HPS M and L Ranges, capable of handling four times more flow than conventional screens in its class.

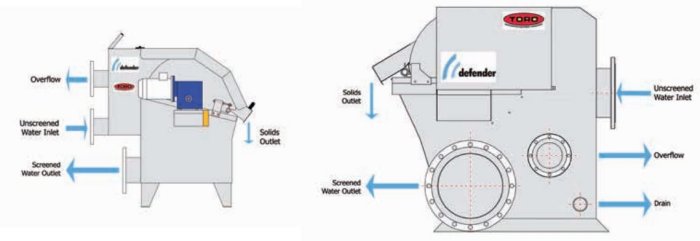

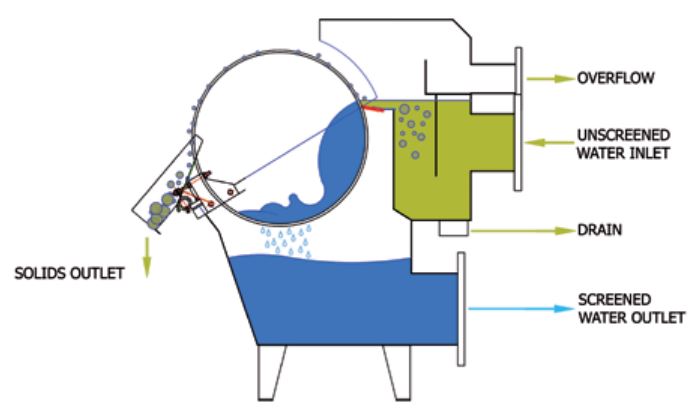

Defender Rotary Screens are pre-treatment polishing equipment in the process of removing solid-liquid waste through a filter drum formed by a grating or perforated mesh of different apertures depending on the type and amount of solids being treated.

Their task is to remove the solids carried by the water in order to avoid obstructions and mechanical problems in the plant.

They are stand-alone units with self-cleaning systems and automatic drive operation.

In municipal water they frequently permit replacement of primary clarifiers, providing elimination of coarse sands and up to percentages of 30% of grease and effluent excess. The apertures used are from 0.50 to 0.15 mm.

Simple operation:

- The discharge to be treated enters through the flange located on the outside of the screen body, being uniformly distributed by the spillway and overflow over the drum filter.

- The solids are retained on the drum surface while it rotates, the discharge entering through the mesh performs a self-cleaning function as it passes again through the bottom of the drum.

- On passing through the external scraper, solids are detached from the mesh, and fall from the scraper thanks to gravity.

Equipment Parts:

- FILTER DRUM, made of stainless steel by the spiral winding of a triangular section on longitudinal ribs grating mesh or a drum perforated with different diameters. The base of said triangular mesh grating or diameter coincides with the external surface of the drum. This strong, rigid assembly retains the solids on the outer surface of a size greater than the opening used and prevents the formation of clusters inside.

- FILTER BODY, in which the drum filter is fixed at its front by bearings. At the rear it has an unscreened water receiving tank that distributes it in laminar flow.

- CLEANING SCRAPER, which removes the solids deposited on the surface of the filter drum.

- DRIVE UNIT consists of a reduction-gear motor coupled directly on the filter drum shaft providing this with a rotational movement.

- SCREENED WATER RESERVOIR, is situated below the filter body and collects the filtrate which is extracted through a flanged pipe.

- CLEANING SYSTEM, located inside the filter drum, fitted with jets that project water under pressure on the inner face of the cylinder to achieve complete cleaning.

Advantages and Applications:

- Made of stainless steel type 316 L.

- Includes safety and splash-suppression lid as a standard feature in the 40 Range.

- Emergency stop and solenoid valve for cleaning.

- Internal cleaning system with jets.

- External cleaning system with scraper.

- The equipment is guaranteed against defects in materials and workmanship under normal use and maintenance.

- Toro Equipment provides commissioning and after sales service, contact us.

Applicable to any wastewater pre-treatment:

- Trash collection.

- Foodstuff manufacture.

- Breweries and wine cellars.

- Meat processing.

- Canneries.

- Dairies/Creameries.

- Tanneries and textile industries.

- Municipal wastewater.

- Fish processing.

- High oil content applications.

- Washhouses.

- Bio-diesel production.