- Home

- Companies

- Advanced Micro Instruments, Inc. (AMI)

- Products

- AMI - Model 221R - Standard Oxygen ...

AMI - Model 221R -Standard Oxygen Deficiency Monitor

The AMI MODEL 221R has become the gold standard for oxygen deficiency & confined space monitoring throughout the US market. It is used by the thousands in US Government Laboratories, Space Agencies, Universities, and a broad range of industries, ensuring the safety of personnel. The MODEL 221R is designed for use in NON-FLAMMABLE applications and provides an incredibly accurate and stable reading over a broad temperature range (0-130°F). The Analyzer is virtually maintenance-free with its unique oxygen sensor delivering a 10-year life expectancy.

- Waterproof enclosure may be washed down

- Provides a warning alarm at 20.0% and a danger alarm at 19.5% (per OSHA standards).

- Alarm set points set per OSHA standards

- 10 year expected sensor life

- No nuisance alarms caused by sensor drift

- Virtually unaffected by barometric pressure change

- Virtually unaffected by temperature change

- Battery backed up against power failure

- 95dBA danger warning audible alarm

- Red backlit oxygen display

- Case can be padlocked

- Remote indication of readings and alarms

- Optional remote oxygen probe available

- UL 61010-1 approved and CE Marked for European use.

The model 221R offers a number of compelling features that make integration into building or plant alarm systems easy.

It provides two alarm relays, operating in fail-safe mode that provide up to 110V at 5A switching capability. They respond to the standard OSHA alarm levels of 20.0% warning, 19.5% danger, and they also respond to a 23.5% over-enrichment situation.

The front panel status LED changes color when an alarm occurs, and when a danger alarm occurs the built-in audible alert sounds. This alarm can be temporarily silenced.

It can be calibrated using a known clean air sample, but it only needs calibration bi-annually, and then mainly in order to verify its calibration.

It provides an isolated 4-20mA output corresponding to the oxygen reading that can be monitored by an analog control panel.

It provides a bi-directional RS-485 communication system that can monitor all the internal parameters and even download a data log of readings over the previous fifteen days.

It can be mounted on a wall, and hosed down. It is available with a remotely mounted oxygen probe, so that the display and alarm can be seen outside a room while the air within the room is monitored, so personnel may be kept out when conditions are dangerous.

It contains enough batteries to allow it to continue operating up to an hour after power failure, and it will indicate an alarm for a period before the batteries completely die.

Finally – we use a number of these in our own plant in places where we keep liquid nitrogen Dewars.

- 0-25% Measurement range

- Large 3 ½ digit Red Backlit digital display

- 2 oxygen concentration alarms. Preset for OSHA standards 20.0% Caution and 19.5% Danger.

- Danger alarm if oxygen exceeds 23.5%

- Status LED

- 95dBA danger alarm preset for 19.5% and 23.5%

- Customer selectable security lockout feature*

- Customer configurable alarm logic*

- Data logger*

- Battery back-up

- Isolated 4-20mA analog output signal

- RS-485 bi-directional communications

- Unmatched stability and repeatability

- RFI protected

- Wide operating temperature range

- 10 year life expectancy zirconium oxide sensor

- Weather tight NEMA 4X package

- Optional remote oxygen sensing probe. Can be located up to 300’ away from control unit

- Gas connection: Diffusion screen. No pump, sample tubing or fittings required

- Compact size

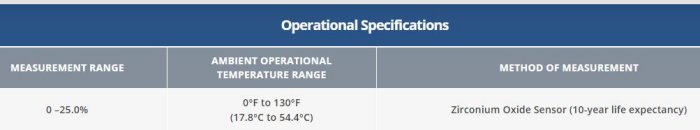

- Measurement range: 0- 25%.

- Red Backlit Digital display: 3 ½ digit LCD. Reads full scale from 00.0% to 25.0%.

- Alarms: 2 preset oxygen concentration alarms. Preset for OSHA standards23.5% Danger. Dry contacts 3A. @24VDC/115VAC.

- Status LED: indicates Power, Safe Operation, Alarm Conditions and Loss of AC power.

- Danger alarm: 95dBA danger alarm preset for 19.5% and 23.5%.

- Battery back-up: 1 hour.

- Analog output signal: Isolated 4-20mA.

- Data logger: Logs data for 10 days @ 1 minute ntervals, 20 days @ 2 minute intervals, etc.

- Communications: RS-485 bi-directional.

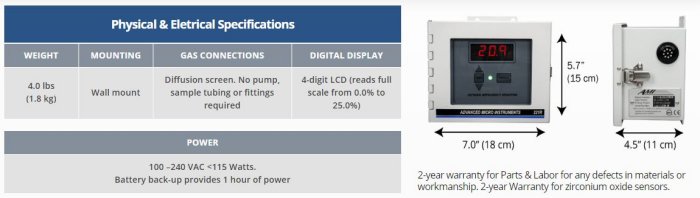

- Power requirements: 100-240VAC < 15 watts.

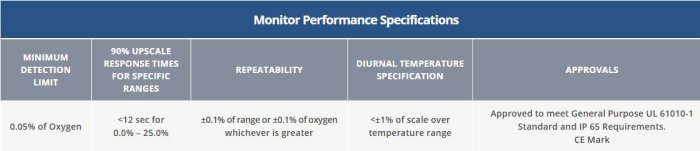

- Minimum detection: 0.05% of oxygen.

- Repeatability: +/- 0.1% of range or +/- 0.1% of oxygen, whichever is greater.

- Operating temperature range: 0˚F to 130˚F.

- Diurnal temperature specification: < +/- 1 % of scale over temperature range.

- 90% full scale response times for specified range: 0-25%

- Long life zirconium oxide sensor: 10 year life expectancy , 2 year warranty.

- Area Classification: Approved to meet General Purpose UL 61010-1 standard and IP 65 requirements. CE Marked.

- Gas connection: Diffusion screen. No pump or fittings required.

- Mounting: Wall mount or 2.0” pipe mount.

- Dimensions: 7.0”W x 5.7”H x 4.5”D.

- Weight: 4 lbs.

Designed for OSHA Compliance

The MODEL 221R is optimized for safety. Our standard offering provides (3) OSHA-compliant preset alarm relay contacts and a single 95 decibel audible alarm. The “Caution” alarm is preset for 20.0% oxygen, Danger for 19.5% and the Enriched Oxygen alarm for 23.5%. Both the 19.5% Danger and 23.5% Enriched Oxygen condition trigger alarm relay contacts and the 95dB audible alarm to alert personnel of the potentially dangerous situation. This Analyzer is also NRTL-certified to be compliant with UL61010-1, covering safety requirements of equipment for measurement, control and laboratory use.

Long Life Zirconium Oxide Sensor Technology

AMI’s zirconium oxide sensors are virtually maintenance-free, extremely accurate and stable over a wide temperature range without suffering from changes in barometric pressure. This unique sensor is the perfect choice for reliably measuring percent levels of oxygen in confined spaces, tank storage area, or in the workspace, ensuring personal safety. AMI’s zirconium sensor in the MODEL 221R will last up to 10 years without ever needing replacement.

Optional Remote Probe

The MODEL 221R is available with an optional remote probe for continuous monitoring of locations separate from the control unit. This makes it an ideal solution for making sure difficult to access locations continue to have a safe oxygen level. The remote probe comes standard with a 12 ft (3.6m) cable, but they can be extended by the customer up to 300 ft (91.4m). The probe features the same long-life zirconium oxide sensor as the standard MODEL 221R.

Full Suite of Standard Features

The MODEL 221R comes standard with a 4-20mA isolated output signal and Modbus bi-directional RS485 communication. It has built-in safety features including rechargeable battery backup and tamper resistant alarms to prevent user override of safety setpoints. It also offers advanced features that can be accessed through AMI’s COMMAND CENTER Software. These includes automatic data logging that provides detailed time-stamped records of O2 measurement, and power supply voltage, as well as calibration history.

- Alarms

- 2 Oxygen Concentration Alarms with Relay Contacts

- Analog Outputs

- 4 − 20mA isolated analog output signals

Command Center

- Software that works across AMI’s Analyzers and gives users access to advanced functions:

- Calibration Details

- Alarm Configurations

- Data Logger (records O2 measurements, temperature, psig, and power)

- Accessories

- Zirconium Oxide Sensor (note: sensor is not field replaceable)

- Remote Probe (note: must be purchased from AMI)