Komptech Americas, LLC

- Home

- Companies

- Komptech Americas, LLC

- Products

- Komptech - Model Multistar 3SE - ...

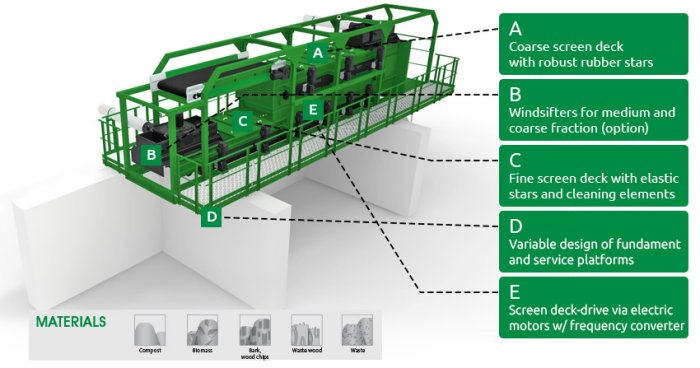

Komptech - Model Multistar 3SE -Stationary Star Screen

Multistar 3SE Stationary Star Screen.

Most popular related searches

starscreen

coarse screen

particle sizing

coarse screening

stationary screen

fine screen

fine screening

conveyor scale

screen separator

wind sifting

- Separation into two, three or four fractions, wind sifting, magnet-separation in one compact machine

- Patented Cleanstar®-cleaning system for high throughput and precise selectivity-even with moist materials

- Simple speed control at the screen deck to change particle size in seconds

- Flexibly tailored solutions for specialist customer applications

DRIVE

Power (kW): 22 (Fine) 12 (Coarse)

SCREEN UNIT

Length x Width: 5985x1200/7.2(Fine)

(mm) / area (m²): 5863x1200/7.0(Coarse)

FEED HOPPER (optional)

Hopper volume (m³): -

SCREEN SECTIONS

- Fine (mm):

- 8 ..... 20

- 10 .... 25

- Coarse (mm):

- 30 .... 60

- 60 .... 90

- 90 .... 120

- 120 .... 150

THROUGHPUT (dependent on material)

Throughput performance (m3/h): up to 180

MULTISTAR 3-SE

DRIVE

Power (kW): 22 (Fine) 12 (Coarse)

SCREEN UNIT

Length x Width: 5985x1200/7.2(Fine)

(mm) / area (m²): 5863x1200/7.0(Coarse)

FEED HOPPER (optional)

Hopper volume (m³):

SCREEN SECTIONS

- Fine (mm):

- 8 ..... 20

- 10 .... 25

- Coarse (mm):

- 30 .... 60

- 60 .... 90

- 90 .... 120

- 120 .... 150

THROUGHPUT (dependent on material)

Throughput performance (m3/h): up to 180

Machine type: Multistar 3-SE

Application: Woody biomass

Throughput: 200 m3/h

The Multistar is fed with shredded biomass by an upstream hopper with a capacity of 20 cubic metres. The screen separates into three fractions: Fines for composting, a fuel fractions with defined particle size, and woody oversizes which go back for reshredding. Electronic conveyor scales give precise data on output, which allows remote access at any time.