- Home

- Companies

- Lindner-Recyclingtech GmbH

- Products

- Lindner Micromat - Model 1500/2000 HP - ...

Lindner Micromat - Model 1500/2000 HP -Stationary Universal Shredding Machine

GIVES NEW LIFE TO END-OF-LIFE PLASTICS: THE SPECIALIST FOR SUPREME QUALITY. Single-shaft shredder with direct belt drive, unique Mono-Fix technology and light-ning-fast safety clutch: this formula makes the Micromat HP series the benchmark for individual and flexible shredding of post-consumer and post-commercial plastics. The gearless drive of the Micromat HP series ensures continuously high throughputs at high speeds and, thanks to Lindner’s safety clutch, maximum protection against non-shreddables. More info on: www.lindner.comLindner`s original: tried and tested a thousand times over, our internal pusher allows for easy and secure machine feeding. Our years of experience and continuous development have left their mark on its distinctive design.

Constant shredding

due to uniform material feeding.

Easy feeding

with a completely internal construction. Maintenance-free thanks to the absence of guide elements.

No jamming

as a result of additional comb and sealing bars.

UP TO 250% MORE OUTPUT

with post-consumer or industrial film thanks to the robust high-speed belt drive with over 1,500 cuts per minute.

POWERFUL SHREDDING

due to high-torque, high-performance motors.

OPTIMUM MACHINE PROTECTION

thanks to the safety clutch and the drive unit’s instant mechanical disengagement in the event of incidents.

GLOBAL AVAILABILITY

of all easy-change standard parts.

The swivel-mounted, hydraulically operated screen unit allows for easy and comfortable access for maintenance and refitting. The screens are available with various mesh widths and can easily be changed by hand by just one person – so you can quickly customise the shredder to the particle size you need.

FLEXIBLE OUTPUT SIZES

possible with our quick-change screen units in various hole sizes.

EASY SCREEN CHANGE

thanks to their swivel-mounted, hydraulically operated, modular design.

EXTREMELY SAFE OPERATION

with the electromagnetically locked screen access point.

due to the powerful motor, an efficient and gearless direct belt drive.

Resistant to non-shreddables

due to robust design and special wear plates.

Precisely cut flakes

guaranteed by the new 3D stepped rotor design.

The hydraulically operated, inward-opening maintenance door allows you to quickly and safely access the cutting system for maintenance work or swiftly remove foreign objects with minimum material leaks.

FAST CLEANING AND READINESS FOR DIFFERENT INPUT MATERIALS

thanks to easy access to cutting unit and pusher.

ENJOY CONVENIENT ACCESS

to the rotor and counter knives for a fast knife exchange with the maintenance door at position 3.

QUICK AND CLEAN REMOVAL OF NON-SHREDDABLES

with the maintenance door at position 2.

ERGONOMIC OPERATION

with activity-dependent ports for the mobile panel on the front and rear of the machine.

HIGH AVAILABILITY

thanks to fast troubleshooting with smart solution-finding and integrated FAQ database.

INTUITIVE MENU NAVIGATION

with software functions automatically opening and closing depending on the task at hand.

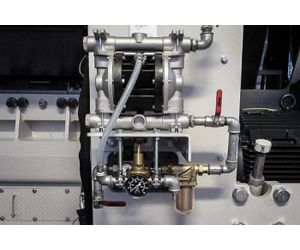

ROTOR COOLING SYSTEM

The closed-circuit rotor cooling system allows for unproblematic shredding of temperature-sensitive materials with low melting points and prevents the final product from lumping as a result of the heat created during the shredding process.

WATER SPRINKLING SYSTEM

Our optional water sprinkling system to reduce air-borne dust at the filling area offers a central water pipe with four nozzles in the enclosed hopper with suction point which can be easily activated via the control panel or the remote control. The system is designed for year-round use (down to -25°C).

FIRE EXTINGUISHING SYSTEM WITH SPARK DETECTION

The fire extinguishing system detects sparks and overheated objects, protecting the system when easily flammable materials are being processed. The sensors monitor not only the shredder but also the discharge conveyor and where necessary trigger the extinguishing process. Thanks to the central water supply, the pressure tank is subsequently filled automatically and once again ready for use.

BALE OPENER

Our Lindner Micromat can be turned into a primary shredder and bale opener for defined material flows with the addition of our smart optional cutting feature, the optimised bale opener.