- Home

- Companies

- Dragon Water Technologies Ltd (DWT)

- Products

- Encore - Model S - Stepper Motor-Driven ...

Encore - Model S -Stepper Motor-Driven Diaphragm Dosing Pump

The compact stepper motor pump, coupled with its intelligent drive concept, combines the big advantages of a solenoid-driven diaphragm dosing pump with the precision of a motor-driven diaphragm dosing pump. The Encore® SK series is available in four capacity ranges. Several different materials and connections are available for suction and discharge side, depending on the specific applications. A coordinated accessory set consisting of hoses, injection nozzles and suction lines enables fast installation while achieving optimum results. Reliable Dosing of Chemicals: Stepper motor driven diaphragm pumps are particularly suitable for highly accurate, reproducible applications due to their design. Most chemicals can be safely fed into the respective processes using these pumps.

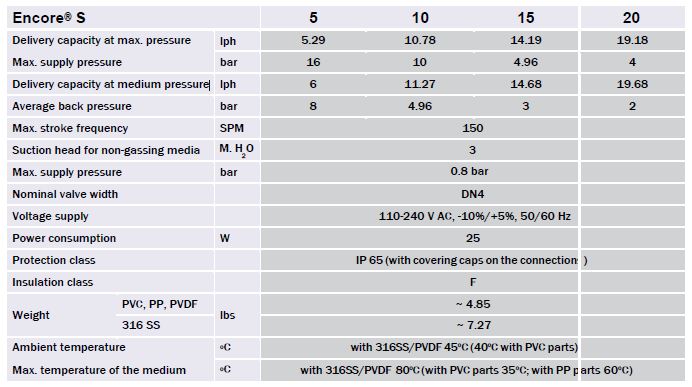

The Encore S is available in four sizes for metering applications ranging to 19.68 lph against pressures of up to 16 bar.

The compact stepper-motor pump, coupled with its intelligent drive concept, combines the big advantages of a solenoid-driven diaphragm dosing pump with the precision of a motor-driven diaphragm dosing pump.

A wide range of materials and connections are available to comply with specific applications. By using appropriate and recommended materials, the Encore S can be used in many process applications.

A matching accessory kit with hoses, injection nozzles and suction lines from our comprehensive accessory range means that nothing stands in the way of a quick installation, and you get the best results.

The drive of Encore S is fully adjustable. The stepper-motor with its wear-free tooth belt drive, ensures a particularly homogeneous and gentle dosing process. Pressure and suction strokes can be per- formed at different speeds. This produces a constant supply stream, which gives you lowpulsation dosing.

In addition, the Encore S gives you the ability to reduce the suction speed in two steps to easily and more precisely supply even viscous dosing media.

The Encore S doesn’t just impress with its elegant design; its multilingual graphical display as well as integrated keypad simplifies its use.

If required, the dosing pump can be controlled via an analogue or pulse input. For integration into demanding automation networks, a version with an Ethernet-based MODBUS interface is available.

Over-dosage as a result of unexpected pump shutdown and the associated downtime is ruled out thanks to the level input alarm.

- Capacity range to 19.68 lph, up to 16 bar

- Wide-range power supply 110 - 240 V AC, 50/60 Hz, 25 W

- Multilingual, high-resolution graphical display

- Precise pump adjustments using the keypad

- Flow rate displayed in various units

- Infinitely variable stroke frequency from 0 to 100%

- Calibration functionality

- External control via standard signal 0/4 – 20 mA

- External control with impulse increase and reduction

- Fully controllable stepper-motor drive

- Accurate dosing thanks to the double-ball valves

- Materials: PVC, PP, PVDF and Stainless Steel

- Automatic diaphragm change program

- Compact design, low space requirement

- Integrated dosing head venting device (plastic version)

- Wall and floor mounting without a bracket

- Supplied with connection sets (plastic version)

- Material consistency from pumps to accessories

- Batch dosing with interval and timer functions

- Ethernet interface (optional)

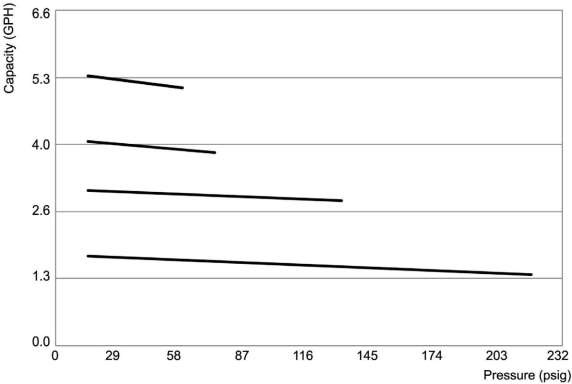

The flow curves are valid for 20°C (68°F) for water at 100% stroke frequency. The delivery capacity depends on the medium (density and viscosity) and temperature.

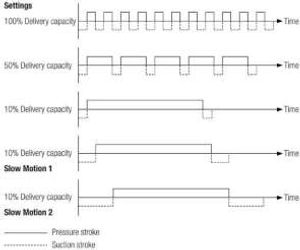

The Encore S dosing pump is designed to run the pressure stroke and suction stroke at different speeds. For low supply rates, for example, the dosing pump performs the suction stroke at the maximum speed and adjusts the speed of the pressure stroke to match the desired supply rate. This produces a constant supply stream, which gives you lowpulsation, smooth dosing.

In Slow Motion mode, the dosing pump has the ability to reduce suction speed in two steps. Viscous dosing media can be conveyed easily and more accurately.

Even the best pump can be improved – simply by the addition of appropriate accessories.

Suitable sets of accessories, consisting of suction/discharge tubing, foot valve and injection nozzle, are available for the dosing pumps.

To turn your dosing pump into an efficient dosing system, we recommend using the following accessories:

- Injection nozzles - to dose the medium into the main line and to prevent it from flowing back into the pressure line.

- Back pressure and pressure relief valves - to increase dosing accuracy or to protect the system against excessive pressure.

- Pulsation dampener - to dampen supply flow as well as to reduce discharge flow pulsations.

- Priming aids - to significantly ease priming of dosing pumps with low supply volumes per stroke, for large suction heights, highly viscous dosing media, for initial priming or when priming after the system has been idle.

- Suction pressure regulator - to prevent medium flow when the dosing pump is not running or to prevent a vacuum being formed in the event of a pipe failure.

Legend

- Encore S

- Injection Nozzlewith Shut-off Valve

- Pulsation Dampener

- Pressure Relief Valve

- Electrical Agitator

- Dosing Tank

- Shut-off Valve

- Suction Pressure