MKR - Model SF 250 HD -Suction and Filter Cart

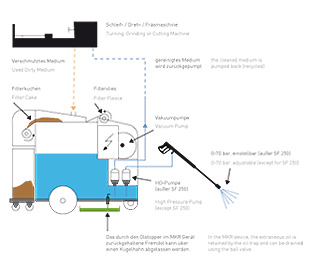

Specific Characteristics: Capacity 250 liters, Filtration by Nylon Filter Insert 150 µm, Throughput 120 l/min, Compact Design, High Pressure Cleaning System, (either fresh water or emulsion).

- Perfect emulsion treatment for individually filled machines

- Change of emulsion as fast as possible

- Useable for emulsions and cutting oils

- 4 Functions in one device:

- Withdrawal of the entire content by suction

- Filtration of the liquid

- Cleaning of the containers for the emulsion and the interior of the machine with the high pressure cleaning system

- Suctioning off the swarf and grinding slurry

Options

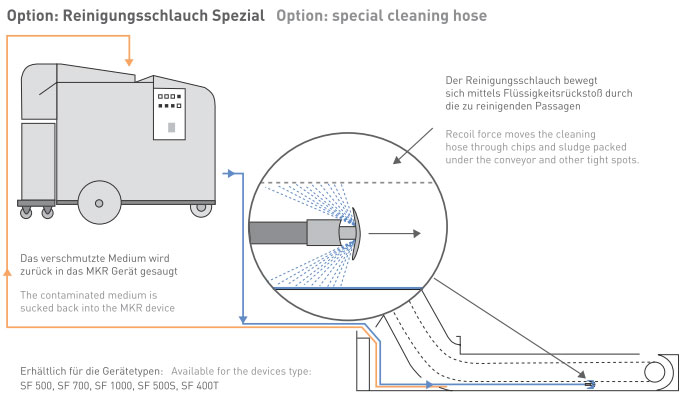

- Special Cleaning Hose

- Stainless Steel Basket 200 µm

- Custom Colour

Housing

Weldment of 3mm sheet steel

Out- and Inside coat of lacquer 2-K-lacquer

(NCS-S 2010-R70B)

Evacuation pump

230 Volt 50 Hz

Power 60 l/min at 1 bar

Hoses

Suction hose, length 3m, Ø 50 mm

Recirculating hose – cleaned medium,

Length 4 m, Ø 20 mm, type Armorvin - HNA

Suction-accessories

Suction-pipe Ø 50 mm, 800 mm long

Flat-nozzle 100 mm wide, for suction-pipe Ø 50 mm

Bushing from Ø 50 to Ø 36 mm

Extension piece Ø 36 mm

Crevice nozzle

Soil nozzle 400 mm wide with adjustable rollers

Cleaning system

High pressure pump for cleaning of emulsion-container

400 V – 2,6 kW, 8 m HD-hose, continous adjustable

lance-nozzle 0-70 bar

Filter insert

150 μm

Documentation

Manual instruction, wiring diagram

Suction:

Use the suction spout to safely remove dirty coolants, chips and swarf. The high-power pump delivers sufficient suction to cut the cleaning times for the machine and emulsions to a minimum.

Filtration:

Using vacuum filtration, chips and swarf up to a size of 80 µm are reliably removed from emulsions.

Pneumatic Lance:

The high pressure of the pneumatic lance will purge even the most stubborn sediments and oily residues from every last nook and cranny inside your machines.

Chip and Swarf Disposal:

The disposal unit retains the filtered out metal particles. Use it separately as a fully functional industrial vacuum cleaner.