- Home

- Companies

- MKR Metzger GmbH

- Products

- MKR - Model SF 1000 - Suction and ...

MKR - Model SF 1000 -Suction and Filter Cart

Specific Characteristics: Capacity 1000 liters, Filtration by Filter Fleece, Throughput 320 l/min, High Pressure Cleaning System, (either fresh water or emulsion), Mechanical “Tramp Oil Stopper”.

- Perfect emulsion treatment for individually filled machines

- Change of emulsion as fast as possible

- Useable for emulsions and cutting oils

- 4 Functions in one device:

- Withdrawal of the entire content by suction

- Filtration of the liquid

- Cleaning of the containers for the emulsion and the interior of the machine with the high pressure cleaning system

- Suctioning off the swarf and grinding slurry

- Cleaning Opening at the rear 420x150 mm

- Cleaning Door at the rear

- Wheel-Set for extremely uneven ways

- Trailer draw bar

- Electrical Actuation with battery and charger

- Special Cleaning Hose

- Custom Colour

- Housing :

- Compact construction with self-supporting Solid-weldingconstruction of 3 mm steel sheet

- Outside- and inside double coating, 2-K-varnish (NCS-S 2010-R70B)

- Suction Hose : Length 4,5 m, Ø 50 mm, suction hose 0,8 m, flat nozzle 100 mm wide

- Nozzle-set : Reducer Ø 36 mm, extension piece Ø 36 mm, length 440 mm, floor nozzle 400 mm wide, crevice nozzle

- Cleaning System : High pressure pump for cleaning of the emulsion tank 400 V - 2,6 kW 8 m HP-hose, continuously adjustable lance nozzle 0-70 bar

- Evacuation : Centrifugal pump, 400 V – 0,55 kW

- Evacuation Hose : Length 5 m, Ø 32 mm, with ball cock at the hose-end

- Vacuum Belt Filter : To the separation of splinters and particles, Fleece-length 100 m

- Electrical connection : 16-A-Cekon-connector with 10 m current cable 5-pin integrated phase inverter

Options

- Drawbar : (The whole length increases by 250 mm.)

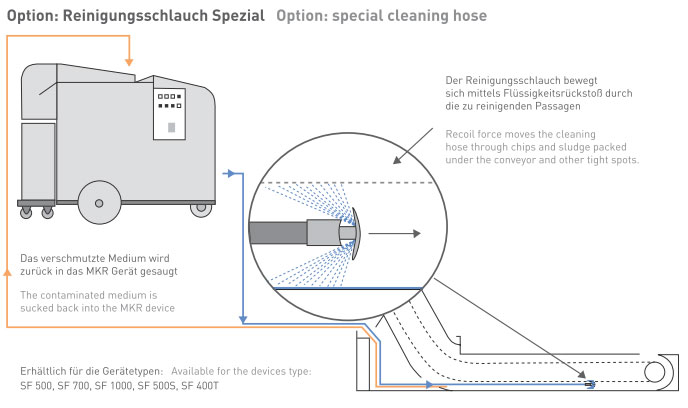

- Cleaning hose special : Length 4 m (For to heavy accessible places, which can not reached with the rigid lance, e.g. under the swarf absorber.

- Cleaning opening at the rear : Dimensions 420 x 150 mm (We recommend this cleaning opening for the unproblematic cleaning of the system)

- Cleaning door at the rear : Breadth: Tank-breadth, height: 500 mm (We recommend this cleaning opening for the unproblematic cleaning of the system)

- Wheel set for extremely uneven ways : Electric drive with battery and battery charger (The system become longer by 378 mm, the weight increases round 165 kg.

- Documentation

- Operation manual

- Parts-catalog

- Wiring diagram

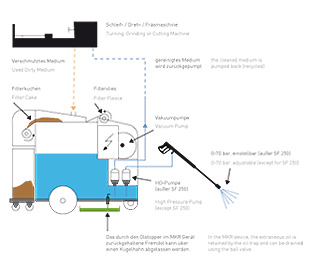

Suction:

Use the suction spout to safely remove dirty coolants, chips and swarf. The high-power pump delivers sufficient suction to cut the cleaning times for the machine and emulsions to a minimum.

Filtration:

Using vacuum filtration, chips and swarf up to a size of 80 µm are reliably removed from emulsions.

Pneumatic Lance:

The high pressure of the pneumatic lance will purge even the most stubborn sediments and oily residues from every last nook and cranny inside your machines.

Chip and Swarf Disposal:

The disposal unit retains the filtered out metal particles. Use it separately as a fully functional industrial vacuum cleaner.