- Home

- Companies

- MKR Metzger GmbH

- Products

- MKR - Model SF 400 T - Suction and ...

MKR - Model SF 400 T -Suction and Filter Cart

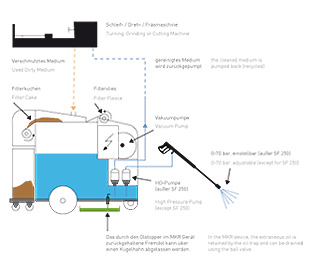

Specific Characteristics: Capacity 400 liters (optional 700 or 1000 liters), 1. Step: Filtration by Filter Fleece, 2. Step: Filtration by Three Phase Drum Separator (filtration grade > 5µm), Optional Bypass Cleaning by the Drum Centrifuge, Throughput 250 l/min, High Pressure Cleaning System (either fresh water or emulsion).

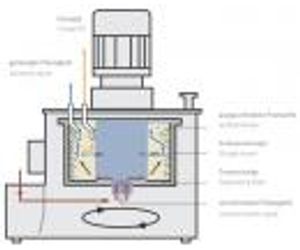

- Combination of suction filter cart and drum centrifuge

- Perfect emulsion treatment for individually filled machines

- Change of emulsion as fast as possible

- Useable for emulsions and cutting oils

- 4 Functions in one device

- Withdrawal of the entire content by suction

- Filtration of the liquid

- Cleaning of the containers for the emulsion and the interior of the machine with the high pressure

- cleaning system

- Cleaning Opening at the rear 420x150 mm

- Cleaning Door at the rear

- Wheel-Set for extremely uneven ways

- Trailer draw bar

- Electrical Actuation with battery and charger

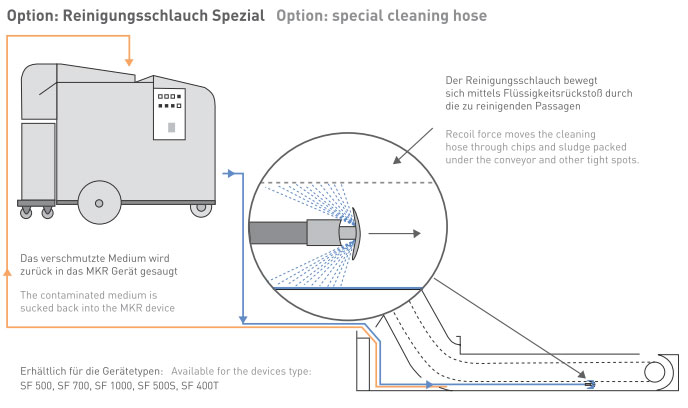

- Special Cleaning Hose

- Custom Colour

Housing

Welded structure of 3mm steel sheet

Outside- and interior lacquer finish 2-way 2-K-Lacquer (NCS-S 2010-R70B)

Vacuum-Bandfilter

For coarse separation of splinters and particles

Fleece length 100 m

Siphon pipes

Length 4,5 mm, Ø 50 mm

Length 4 m, Ø 25 mm with a D-hitch installed, for bypass operation

Suction tube 800 mm lang

Breitdüse 100 mm breit

Nozzle set

Reducer Ø 36 mm,

Extension pipe Länge 440 mm

Soil nozzle 400 mm wide

Joint nozzle

Separator-system

Solid-collecting drum separator

Type MKR 3.03, 2- und 3-phases-separation

Capacity:

- 800 -1000 l/h bei 3-phases-separation

- 1000-3000 l/h bei 2-phases-separation

Delivery with 2 mud-in-corrode

Medium-affected separator parts from aluminium

Emptying system

Emptying pump for leading back the medium from the main container.

5 m Emptying hose Ø 25 mm, Ball stop valve at the hose end 3 m Emptying hose, Ø 25 mm with 1 D-hitch for bypass operation

Cleaning system

- High-pressure pump: for cleaning of the emulsion containers 220 V – 2,6 kW

- 8 m HD-hose

- steplessly adjustable lance nozzle 0-70 bar

Splinter suction

- Admission of splinters and mud, removeable, entry ashes for fork lift

- filter fleece transportation, hood rear

Switchgear cabinet

- Equipment for automatic enterprise

- Rotary field identification

- Phases turn-over switch in the CEE-plug

- Announcement and safety device of all containers against overflow

Power connection

16 A-Cekon-plug with 10 m power cabel 5-pin.

Options

Cleaning hose special

Length 4 m

(For hard accessible places, which can not be reached with the stare lance, e.g. under the splinter promoter.)

Cleaning port at the tail

Measures: 420 x 150 mm

(We recommend this cleaning port for a problem-free cleaning of the equipment.)

Cleaning door at the tail

Width: container width, Height: 500 mm

(We recommend this cleaning port for a problem-free cleaning of the equipment.)

Float construction

For surface exhaust in the bypass enterprise

Electric drive with battery and battery charger

(The device becomes 378 mm longer, the weight erhöht increases to 165 kg).

Optional are different sucking of systems available

Documentation

- manual, switch chart

Suction:

Use the suction spout to safely remove dirty coolants, chips and swarf. The high-power pump delivers sufficient suction to cut the cleaning times for the machine and emulsions to a minimum.

Filtration:

Using vacuum filtration, chips and swarf up to a size of 80 µm are reliably removed from emulsions.

Pneumatic Lance:

The high pressure of the pneumatic lance will purge even the most stubborn sediments and oily residues from every last nook and cranny inside your machines.

Chip and Swarf Disposal:

The disposal unit retains the filtered out metal particles. Use it separately as a fully functional industrial vacuum cleaner.