- Home

- Companies

- MKR Metzger GmbH

- Products

- MKR - Model SF 500 S - Suction and ...

MKR - Model SF 500 S -Suction and Filter Cart

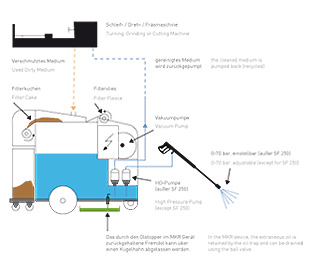

Specific Characteristics: Capacity 500 liters (optional 700 or 1000 liters), 1. Step: Filtration by Filter Fleece, 2. Step: Filtration by Three Phase Disk Separator (filtration grade > 2µm), Optional Bypass Cleaning by the Disk Centrifuge, Throughput 250 l/min, High Pressure Cleaning System (either fresh water or emulsion)

- Combination of suction filter cart and disk centrifuge

- Perfect emulsion treatment for individually filled machines

- Change of emulsion as fast as possible

- Useable for emulsions and cutting oils

- 4 Functions in one device:

- Withdrawal of the entire content by suction

- Filtration of the liquid

- Cleaning of the containers for the emulsion and the interior of the machine with the high pressure cleaning system

- Suctioning off the swarf and grinding slurry

Options

- Cleaning Opening at the rear 420x150 mm

- Cleaning Door at the rear

- Wheel-Set for extremely uneven ways

- Trailer draw bar

- Electrical Actuation with battery and charger

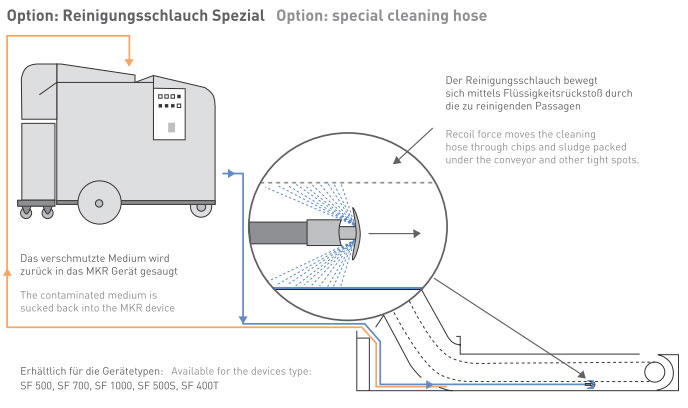

- Special Cleaning Hose

- Custom Colour

Housing

Welded-construction with 3 mm steel sheet

Outside- and inside double coating 2-K-varnish (RAL 5014 pigeon blue)

Switch cabinet, rear hood and swarf-receiver-tank 2-Kvarnish (RAL CS201 R70B grey)

Vacuum-belt-filter

To the coarse separation of swarfs and particles

Fleece lenght 100 m

Suction hoses

Length 4,5 m, Ø 50 mm, suction tube 0,8 m,

Broad nozzle 100 mm broad

For bypass operation: length 4 m, Ø 25 mm with a

D-coupler, installed

Nozzle set

Reducer Ø 36 mm, extension piece

Length 440 mm, Ø 36mm

Floor nozzle 400 mm broad, crevice nozzle

Separator-system

Eccentric screw pump: transport of the prepurified medium to the separator

Solid-collecting 3-phases-disk separator:

Capacity 500 l/h

Medium-contacted separator-parts made auf stainless steel

Emptying system

Vertical inline block pump for leading back the medium from the main or pure tank 5 m emptying hose, Ø 25 mm,

Ball-stop-valve at the end of the hose 3 m emptying hose, Ø 25 mm with a D-coupler for bypass-operation

Cleaning system

High pressure pump to the cleaning of the emulsionstanks

400 V -2,6 kW, steplessly adjustable lance nozzle 0-70 bar, 8 m HP-Hose.

Swarf tank uncouplable

Admission of swarfs and mud

Entry ashes for fork-lift trucks

Filter fleece transport (fleece hasp)

Covering cap in the back

Switch cabinet

Siemens-components

Rotary field identification

Time switch clock (timer) for automatic-operation

Phase turning switch

Announcement and safety device of all containers against overflow

16 A-Cekon-plugs with 10 m current cable 5-pol.

Options

Special cleaning-hose

Lenght 4 m

(For difficulty accessible places, that can not be reached with the rigid lance, for example under the swarf–conveyer.

Cleaning-opening at the rear

Dimensions: 420 x 150 mm

(We recommend this cleaning opening for the problem-free cleaning of the system.)

Cleaning door at the rear

Breadth: tank-breadth, height: 500 mm

(We recommend this cleaning opening for the problem-free cleaning of the system.)

Wheel set for extremely uneven ways

Float construction (surface exhaust)

Hose extensions as required

electric drive with battery and battery charger

(The equipment extends to 378 mm, the weight increases around 165 kg.)

Documentation

- Operation manual

- Wiring diagram

Suction:

Use the suction spout to safely remove dirty coolants, chips and swarf. The high-power pump delivers sufficient suction to cut the cleaning times for the machine and emulsions to a minimum.

Filtration:

Using vacuum filtration, chips and swarf up to a size of 80 µm are reliably removed from emulsions.

Pneumatic Lance:

The high pressure of the pneumatic lance will purge even the most stubborn sediments and oily residues from every last nook and cranny inside your machines.

Chip and Swarf Disposal:

The disposal unit retains the filtered out metal particles. Use it separately as a fully functional industrial vacuum cleaner.