- Home

- Companies

- Pennwalt Ltd.

- Products

- Pennwalt - Super Decanter Centrifuge

Pennwalt - Super Decanter Centrifuge

The Pennwalt Super-D-Canter Centrifuge is a specially developed continuous Solid-Bowl Horizontal Scroll Discharge centrifuge for effective separation of slurries into clarified liquid and dewatered cake solid phases, with the application of centrifugal sedimentation principle.

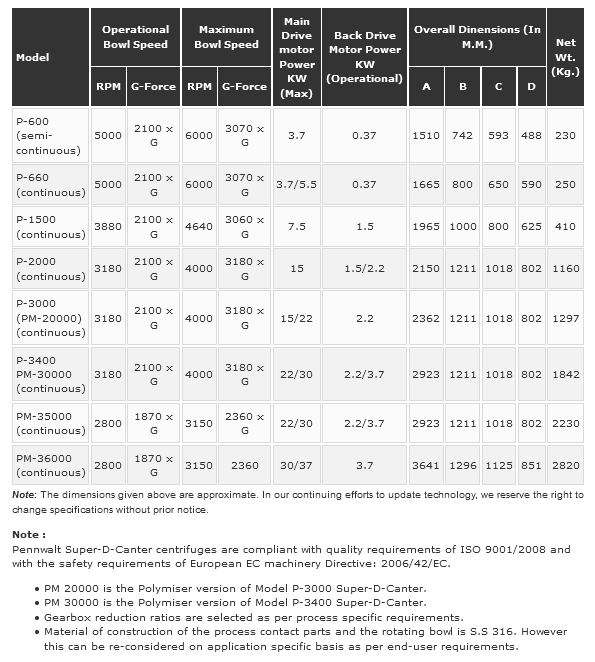

Pennwalt Ltd. are manufacturers of Decanter Centrifuge Models P600, P660, P1500 P2000, P3000/PM20000, P3400/PM30000, PM35000 and PM36000 based on the technology acquired from Sharples Stokes Division Pennwalt Corporation-USA.

Pennwalt also supply spare parts manufactured to international standards that are interchangeable on each of the above models of the Decanter Centrifuge

Solids are continuously separated from the liquid phase by the application of centrifugal force ranging up to 3000 times the force of gravity, efficiently and economically. A characteristic feature of the Pennwalt Super-D-Canter Centrifuge is the cylindro-conical bowl containing within a helical/quasi-axial screw conveyor of matching profile that rotates in the same direction but at a slightly slower speed with respect to the bowl.

Extremely flexible SeparationsTool

- Handles slurries with a wide range of solid particle sizes from 5.0 mm to a few microns

- Handles slurries with insoluble solids content from as low as 0.5%w/v to as high as 55%w/v.

Wideranging,process specific applications of PennwaltSuper-D-Canter Centrifuge encompass:

- Clarification of liquids.

- Dewatering or de-liquoring of insoluble suspended solids.

- Thickening or concentration of insoluble suspended solids.

- Classification of insoluble solids suspended in liquid.

For a detailed list of applications where the Pennwalt Super-D-Canter Centrifuge has been successfully used click here

EconomicalOperation

Pennwalt Super-D-Canter Centrifuge has polymiser features, wherein the feed zone & conveyor flights are modified to reduce the floc breakage and minimise conveyor turbulence in the pool. These features result in considerably reduced dose of polymeric flocculants. In addition there is a substantial economy of space, power and labour required in the operation of the Pennwalt Super-D-Canter Centrifuge in comparison with alternative solid-liquid separations equipment.

Stainless Steel Construction designed to resist corrosion

Carbon Steel corrodes, leading to unbalance, high maintenance costs, long downtimes. Therefore the principle elements and stressed rotating components of Pennwalt Super-D-Canter Centrifuge are machined from quality centrifugally cast Stainless Steel.

Designed to resist abrasion

Sintered Tungsten Carbide Tiles positioned on the flights of the Pennwalt Super-D-Canter Centrifuge scroll (conveyor) outlast conventional hard surfacing systems many times over in any environment.

- Reduces Total disposal volume substantially

- Saves space due to small foot print

- Saves power in comparison with filtration equipment

- Reduces handling costs

- Produces Truckable cake solids discharge

- Totally enclosed casing for odour minimisation and solvent loss minimisation

- Automated Decanter Operation

- Continuous Operation

- Tailored to application specific requirements

The flexibility of Pennwalt Super-D-Canter Centrifuge design has proved to be effective in evolving solutions to a wide range of solid-liquid separations in the Chemical Process Industry.

However, the ideal methodology of evolving authentically tailored optional solutions to specific Solids-Liquid separational problems is to carry out laboratory settling tests, followed by trials on geometrically similar pilot scale test models of the Pennwalt Super-D-Canter Centrifuge with representative samples of process slurries that need solids-liquid separation. On the basis of the test data obtained, an accurate detailed specification of the scaled-up Super-D-Canter Centrifuge can be recommended to the potential customers.

Representative Samples

The results which are obtained in any pilot scale trials testing program can only be as good as the sample which is tested. Therefore it is absolutely essential that the sample sent to Pennwalt Ltd. for conducting trials is representative in the settling / separational and flocculation characteristics of the process slurry feed to the full-scale on-site Super-D-Canter. A similar consideration applies to the separational characteristics of representative test samples of immiscible liquids and fine solids feed sent for trials with the super centrifuge and to the test samples with representative particle size distribution of solids feed sent for trials on the Vibroscreen, which should match the separational characteristics of process feed that would be fed to the separations equipment in the full-scale plant at site.