- Home

- Companies

- Magnetic Systems Internationial | MSI

- Products

- MSI - Suspended Permanent Magnets for ...

MSI - Suspended Permanent Magnets for Industrial Applications

MSI's suspended permanent magnets are designed for demanding industrial environments, providing solutions for separation and the removal of tramp metal. Ideal for conveyor belts with moderate load depths and speeds where electromagnets aren't necessary, these magnets are particularly effective in eliminating larger unwanted metal fragments that other separators might miss. Available in both manual clean and self-cleaning options, MSI's suspended magnets offer an economical choice for infrequent tramp material while ensuring continuous operation in environments with high tramp material frequency through self-cleaning mechanisms. Offering various strengths and sizes, these magnets can be customized according to specific industrial requirements, including various suspension and drive configurations. MSI also provides free testing services to help customers make informed decisions based on their unique application needs.

MSI’s suspended permanent magnets are built for demanding, heavy-duty industrial applications and can be used for separation or tramp metal removal. Suspended permanent magnets are an excellent choice for conveyor belts carrying moderate burden depths and belt speeds where electromagnets are not needed. These magnets are especially helpful in the removal of larger tramp material where other types of magnetic separators may struggle.

Manual clean, permanent magnets offer an affordable solution when tramp material is infrequent, though for best performance, permanent magnets should be kept free of tramp material. The self-cleaning option works to continuously keep the magnet free of unwanted ferrous, especially helpful in recycling applications, when tramp materials may be more frequent, or when magnets cannot be manually serviced on a regular basis.

Available in a variety of strengths and sizes, MSI’s permanent suspended magnets can be engineered for specific applications with a variety of suspension and drive options specific to customer preferences. MSI’s FREE TESTING allows customers to make informed decisions before purchasing.

Manual Clean

Manual clean magnets are generally used in applications where tramp metal volume is low. These are available with manually operating cleaning mechanisms such as swipe arms or slide trays.

Self-cleaning

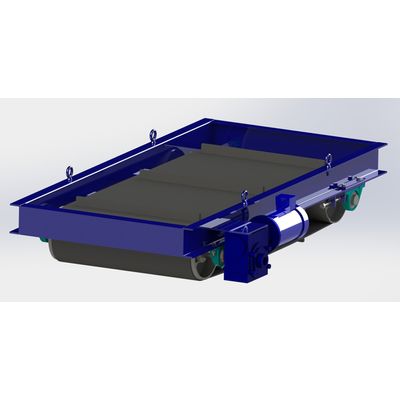

To increase magnet effectiveness, suspended self-cleaning magnets are used for high tramp metal volume to prevent ferrous build-up on the magnet face. These magnets are available with a number of options for the drive, belt, and even tramp discharge.

Material :

- Ceramic

- Rare earth

- Alnico

- Hybrids and combinations

Sizes Available :

- 12” to 72” belt widths

- Up to 16” suspension heights with custom heights available

- Custom sizes

- Application-specific designs

Magnet Dimensions Depends On :

- Belt width

- Suspension height

- Belt speed

- Burden depth/type

- Tramp metal targets

Belts :

- Heavy-duty 2-ply rubber

- Stainless steel cladding

- 2” SBR cleats (standard)

- Alternative cleats and materials available

Drive Options :

- Electric in various configurations

- Hydraulic

- Custom configurations

Popular Options

- Belt guards

- Guidlers for steep inclines

- Customized mounting options

- Carry-over magnetic sections for discharging material away from the conveyor

- Taper-off magnetic sections for easier discharge

- Various belt speeds (popular for inline applications)

- Speed switches

- Single point lubrication

- Turnbuckles and chains