- Home

- Companies

- Shanghai Techase Environment Protection ...

- Products

- Techase - Model TECN - Sludge ...

Techase - Model TECN -Sludge Thickening Press

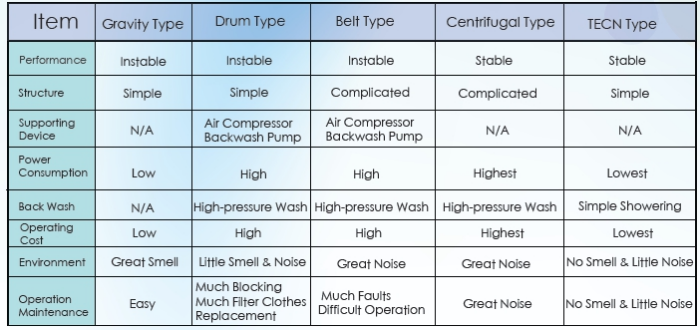

TECN multi-plate screw press is a new type of mechanical waste water concentrating equipment developed by TECHASE Company, which is featured by low power consumption, high efficiency, stability, full-automatic control. It directly and also continuously concentrates the solids of the waste water from the secondary sedimentation tank from 2,000mg/l to 100,000 mg/l. It replaces the sludge thickening pool which causes stinky smell and phosphorous and reduces the capital construction cost and land occupation.

-

A typical multi-plate screw thickener consists of the electric control cabinet, the flocculation tank, the filter part and the filtrate collecting tank. The filter part consists of fixed rings, moving rings and a screw shaft through them.

-

The waste water and the flocculants are mixed well in the flocculation tank and generate floc units of 3~5mm which flows into the filter part and are pushed forward to the discharge end with the rotating of the screw shaft. Along with the pressure inner the chamber getting higher and higher, the filtrate is pressed out from the gap between the fixed rings and moving rings.

-

The rotating of the moving rings automatically cleans the gap between them and the fixed rings thus there will be no blocking problems that all the traditional concentrating equipment have.

-

Wide range of inlet solids content: 0.2%~5%

-

Stable outlet solids content: 4%~10%

-

High efficiency & Small land occupation

-

No blocking & No backwash water

-

Low power consumption, low operating cost, no noise

-

Closed structure, no stinky smell

-

Few wear parts, low maintenance cost, long service life

-

Automatic control, continuous operating, easy maintenance

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity.

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce.

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.

Patents

Techase constantly focus on innovation & improvements of our products to meet the requirements of the market and provide our customers with products of reliability and high performance. So far, we`ve got tens of patents and varieties of pending technologies on Techase® Multi-plate Screw Press.

- Pre-thickening for sludge advanced dewatering system, working before filter presses

- Replacement of the sludge thickening tanks

- Other solids-liquid separation & dewatering processes