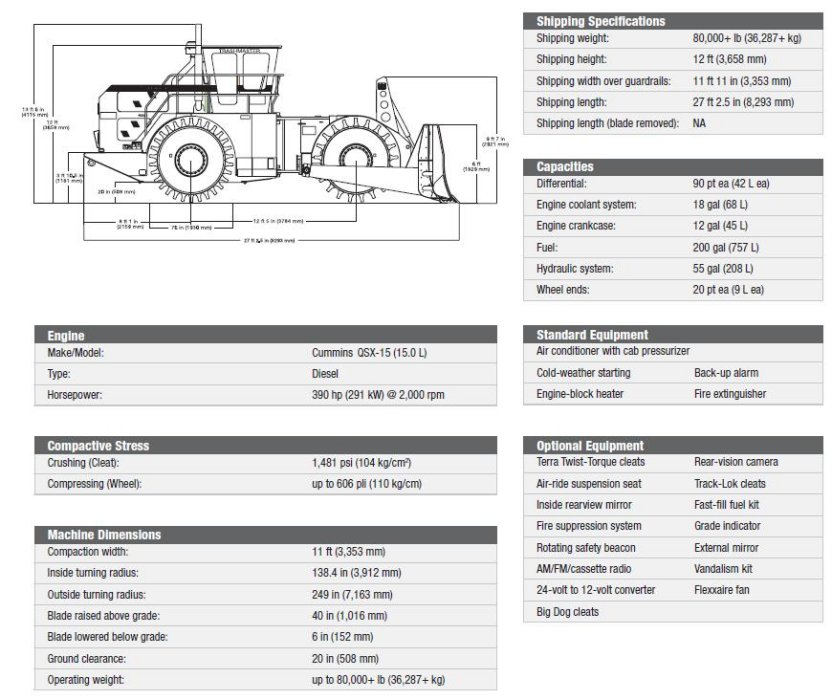

Terex - Model TC400 -Landfill Compactor

Not only do the Terex TC400 and TC550 landfill compactors offer the power and reliability you need for your job site, they’re the industry’s only full-width compactors. With a Terex landfill compactor you also get equal weight distribution, which results in greater densities than conventional compactors provide. No wonder the TC400 and TC550 have the highest PLI ratings in either machine’s class.

Terex Trashmaster Landfill Compactors put their weight to the task like no others. That’s because: 1) they’re the industry’s only full-width compactors…the result of a unique wheel configuration, and 2) they pack more PLI power than any other compactors out there. *PLI stands for “Pounds Per Linear Inch,” which is how compaction force is measured.

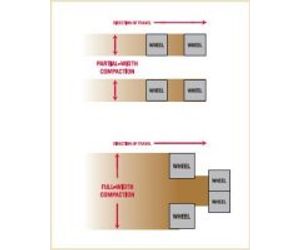

Let’s start by examining the triangular wheel configuration. This is what enables the TC400 to compact an area equal to its wide footprint. In other words, it compacts everything under it, front to back, side to side, in a single pass. Conventional compactors, by comparison, leave an uncompacted “gap” area in the middle of their footprints. You can blame their wheels being located at the four corners of their frames for that. Result? Multiple passes are required to compact a single run. But with a TC400 and its triangular wheel pattern, one pass will do it. The machine’s weight is distributed equally, resulting in greater compaction densities than other compactors provide.Couple

The TC400’s triangular wheel pattern and its high-density compaction force with its available operating weight—80,000-plus pounds (36,287-plus kilograms)—and you’ve got the greatest compaction force in the industry. That’s what PLI is all about: It’s the power to pack more refuse into your landfill and the power to increase density levels, as well as your revenue and your bottom line. And the TC400 has the highest PLI rating of any machine in its class.

Ultimately, this machine outperforms other compactors because it was designed by Terex specifically for the compaction of trash. It’s not just a converted bulldozer or loader outfitted with compactor wheels. What’s more, it’s been around: No other compactor has as long a history of industry acceptance and use.

Full-Width Compaction

- Wide footprint: 11 ft (3,454 mm) across

- Triangular wheel configuration: Large front wheels with steel cleats compact the area between the left and right rear wheels

- No guesswork as to whether you have compacted an area— everything under the TC400 is compacted, ensuring the maximum amount of trash your landfill can hold

- Fewer passes than with loaders—which means less fuel consumption, less wear-and-tear on components and increased machine life

- 22% increase in total width over older models, which greatly improves performance on slopes

Oversized Components

- One of the largest-displacement engines in the industry

- New Tier III Cummins® QSX-15 turbo-charged, intercooled 390 hp (291 kW) diesel engine

- Fuel, lube-oil and coolant systems protected by individual filters

- Cooling air provided by 36 in (914 mm) fan

- Dry-type, replaceable air cleaner—with safety element and service indicator and pre-cleaner

- Self-diagnostic DSM—Drive System Monitor audits engine oil, coolant and transmission oil temperatures and pressures

- Increased horsepower over old models by 11%

- High-Capacity Axles

- Improved design for better longevity and increased capacity

- Oversized Articulated Joint

- Supports both mainframe and bogie

- Oversized Power-Shift Transmission

- Specifically designed for off-highway use

- Capable of withstanding the daily rigors of landfill compaction

- Largest Blade Lift Arms

- “A” frame channel steel

- 5 in (127 mm) boss mount

- Most Advanced Wire Wrap Protection System Steering Cylinder Protection

- Cylinder mounted up and out of trash

- New, Improved Cleat Patterns

- Reduce wheel clogging

- Cut replacement costs of cleats and reduce damage caused by wire wrap

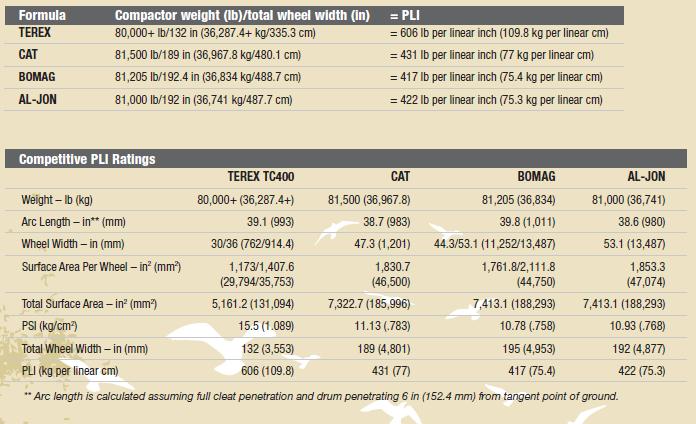

Weight vs. PLI—Compaction Per Linear Inch

Due to the rolling motion of the wheels, the surface area can be simplified to a theoretical line with a length equal to the width of the wheels. This unit is known as PLI—Compactive-effort pounds per linear inch.

Hydraulically Actuated Hood

- The only one-piece hood in the industry

- Electric-over-hydraulic actuation for complete hood lift, rather than hinged or bolted panels

- Allows radiator to be cleaned either from the inside or outside by flushing it with air or water

- Heavy steel safety lock prevents accidental closure of hood during maintenance

- Rear of machine frame designed in a bevel—tapered toward the back which reduces waste build up in belly pan area

- Grilled doors at machine rear deflect air upward, preventing trash from blocking airflow, plus easy-to-access radiator and oil cooler without raising the hood

Self-Cleaning Wheels & Cleats

- Large, self-cleaning 75 in (1,905 mm) diameter wheels—36 in (914 mm) width, rear; 30 in (762 mm) width, front—operate better on slopes without digging in

- Replaceable cleats mounted in chevron pattern that prevents trash from being retained between cleats during operation; also self-cleaning cleats to discourage build-up and eliminate need for raker bars that can sap engine power and restrict ground movement

- Exclusive cleat contour design creates a crisp “chopping” action, which reduces refuse size and eliminates surface “fluffing”

Rollover Protection

- Provided by a certified internal system rated far above machine weight

Cab Permitting Excellent Visibility

- Industry’s only side-facing operator’s seat and large cab windows deliver exceptionally clear view of working environment, whether in forward or reverse

- Largest cab in its class with all-around windows and tinted safety glass; front and rear wipers also enhance visibility

- Better visibility ensures better results: less operator fatigue and fewer missed areas

- Pressurized cab improves operator comfort

- Six-way-adjustable high-back seat has joystick control on each armrest—one controls blade and ground-travel direction, the other controls steering and working speed

Outstanding Density

- Industry-leading density when full weight of TC400 is brought to bear on just one of its forged manganese-alloy steel cleats per wheel

- Wheel configuration directs full weight of machine onto landfill surface, creating the greatest compaction force of any machine in the TC400’s class

- Wider wheel design greatly improves performance on slopes

Service and Maintenance

- Extremely mechanic-friendly

- Built to provide the most maintenance access room of any compactor available

- Hydraulic activation makes hood easy to open, in turn making it easy to service the front and rear—compare that to some other machines, where you have to unbolt cowling to service the product

- Belly pan access is the industry’s largest (one-piece and full-width)

- Terex remote service monitoring available

- Rebuilt components for lower cost options

- Highest fuel capacity of any unit in its class, reducing fueling

Parts Support

- Excellent dealer support program: one part number gets you everything you need for servicing—including hydraulic filters, engine oil filters, breathers, seals and service instructions

- More than $7 million of in-stock consumable parts with one of the industry’s highest fill rates

- Your Terex dealer: your single source for TC400 sales, upgrades, parts and service

Advanced Technology

- Terex Asset Management (TAM)

- GPS Density and Slope Controls

Oil Samples

- Terex online oil-sample reports (terex.eoilreports.com)

- Terex will examine all oils—hydraulic and engine— for contamination (Managed Maintenance Program)

- Diagnosis provided—and, if necessary, troubleshooting

- Helps keep your TC400 running better longer

Financing

- Available through Terex Financial Services

- Operating lease optional for a single monthly payment

Effective Date: June 2008. Product specifications and prices are subject to change without notice or obligation. The photographs and/or drawings in this document are for illustrative purposes only. Refer to the appropriate Operator’s Manual for instructions on the proper use of this equipment. Failure to follow the appropriate Operator’s Manual when using our equipment or to otherwise act irresponsibly may result in serious injury or death. The only warranty applicable to our equipment is the standard written warranty applicable to the particular product and sale and Terex makes no other warranty, express or implied. Products and services listed may be trademarks, service marks, or trade names of Terex Corporation and/or its subsidiaries in the USA and other countries. All rights are reserved. Terex is a registered trademark of Terex Corporation in the USA and many other countries. Copyright 2008 Terex Corporation.