- Home

- Companies

- Stark Solutions

- Products

- Stark Solutions - Model S-500 - ...

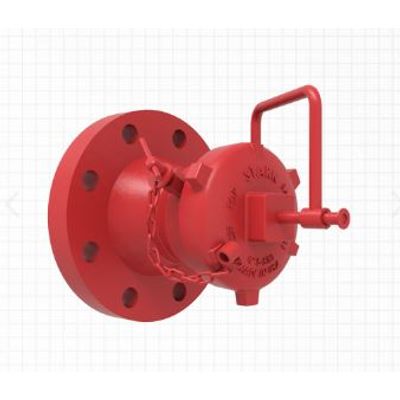

Stark Solutions - Model S-500 -Threaded Closure for Oil and Gas Industry

The Stark S-500 Threaded Closure is a widely used closure in the oil and gas industry, designed for robust performance and cost-effectiveness. Stark has enhanced the standard design to improve operation, incorporating features that eliminate hammering and enhance operator control. Manufactured in diameters ranging from 2 inches to 52 inches (DN50 to DN1300) and pressure series 150 through 2500, it meets various standards including ASME B31.3/B31.4/B31.8 and CSA Z662 Cat. II. The S-500 features a flat sealing surface for optimal sealing across all sizes, and a bidirectional hinge design for versatile operation. Standards for specific sizes include wrench openings and PAV compliance as per ASME BPVC VIII DIV. 1. It operates from -50°F to +400°F (-45°C to 204°C) and offers several optional customizations such as flanged closures, stainless steel weld overlays, and specialized materials and O-rings.

The Stark S-500 Threaded Closure represents historically the most widely used closure style in the oil and gas sector. Based on the industry’s desire for robust and cost-effective solutions, Stark improved upon the standard design to bring operation to a new level. Features to avoid hammering and strengthen operator control were incorporated into the otherwise proven design. The S-500 is manufactured in diameters ranging from 2” to 52” (DN50 to DN1300) and pressure series 150 through 2500.

- Proven and robust design

- Economically priced

- Certified to ASME B31.3/B31.4/B31.8/CSA Z662 Cat. II

- Flat sealing surface for best seal results on all sizes

- Bidirectional Hinge design allows the cap to open to the left and right side

- 2” to 4” (DN50 to DN100) closures designed for wrench opening

- Opening tool supplied with 6″ to 52″ (DN150 to DN1300) closures

- PAV per UG-35.2 of ASME BPVC VIII DIV. 1 on 6” and larger (2” to 4” optional)

- Cap designed per ASME BPVC VIII DIV. 1, U-Stamp compliant

- Nace MR0175 compliant material

- -50° to + 400°F (-45° to 204°C)

- Flanged Closure – welded connection or one-piece

- ASME BPVC VIII DIV. 1 with U-Stamp for whole closure (cap and hub)

- Opening Wrench for 2” to 4″ (DN50 to DN100)

- PAV per UG-35.2 of ASME BPVC VIII DIV. 1 on 2″ to 4″ (DN50 to DN100)

- Stainless Steel and Inconel weld overlay on sealing surfaces

- Custom Wall Thickness, vents, and other modifications

- Special Materials and O-Rings

- Horizontal, Vertical, Inclined or Declined hinging