Binsfeld Engineering Inc

- Home

- Companies

- Binsfeld Engineering Inc

- Products

- Binsfeld TorqueTrak - Model TPM2 - ...

Binsfeld TorqueTrak - Model TPM2 -Torque and Power Monitoring System

The TorqueTrak Torque and Power Monitoring System (TPM2 series) is a rugged precision instrument designed to measure torque and/or power on rotating shafts in real time using precise strain-gage sensors. The TPM2 is custom designed to fit on shafting as low as .75″ (19mm) and up to 48″ (1220 mm) in diameter. Machine disassembly is not required.

Most popular related searches

torque monitoring

strain gauge sensor

torque monitoring system

strain gauge

shock test

vibration test

strain sensor

centrifuge

built environment

- .1% Instrumentation Accuracy

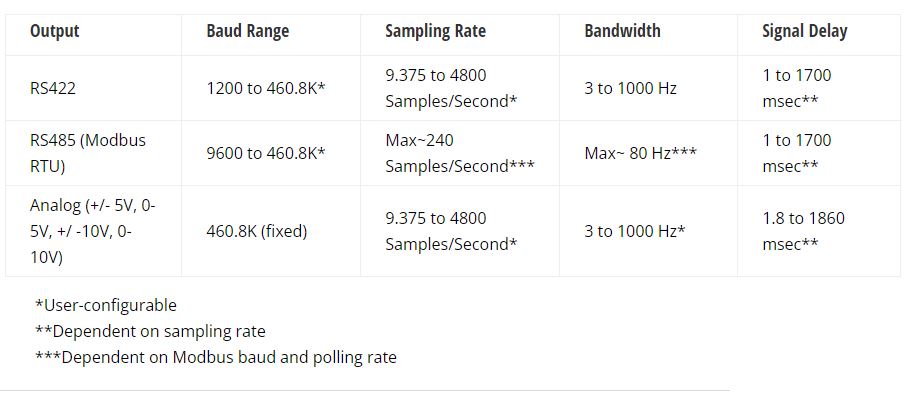

- Multiple Outputs Available

- RS485 Modbus RTU

- Analog (+/- 5V, 0-5V, +/ -10V, 0-10V)

- RS422 High-Frequency Protocol

- One-Time Calibration (No re-calibration required)

- Durable – IP67 rated, Vibration Tested to MIL-STD-167-1A, Shock Tested to MIL-STD-810H

- High RPM / centrifugal g-force rating (For example 6900 RPM at 191mm/7.5″ )

- Fits Small Shafts

- 91mm/3.6″ minimum shaft space

- 19mm/.75″ minimum shaft diameter

- Easy Installation – Rotating Collar and Stationary Ring are split and bolt together around the shaft. No Machine assembly or Shaft modification is required.

- Robust Construction – Sturdy hardware and electronics, built for demanding environments.

- Reliable Operation – Inductive power and data transfer with generous clearance between stationary and rotating parts. No wear surfaces.

- System Status Indicators – Confirm proper operation at a glance. Expedites troubleshooting.

- Easy-on Collar – Rotating Collar is designed to accommodate small variations in shaft diameter and clamps to the shaft using standard tools.

- Communications Made Easy – High-speed bi-directional communications link interfaces with PC or PLC. User-selectable sample rate up to 4800 samples/second.

- Product Support – Backed by BEI’s proven outstanding customer service, before and after the sale.

POWER SUPPLY INPUT:

10 – 30 VDC @ 10 W (nom), 15 W (max)

TORQUE SENSOR

TORQUE SENSOR INPUT:

- Strain gage bridge, 350 ohms (std), 120 ohms (min)

- Input Range: user-selectable from 0.025 to 32 mV/V

- Shunt Calibration: 2 user-selectable: 1 mV/V and 0.2 mV/V (350 ohm bridge)

TORQUE SENSOR RESOLUTION:

- 15 bit (32,768 points)

SHAFT SPEED AND DIRECTION:

Measured once per revolution

Resolution:1 5 bit (32,768 points), auto-ranging

ACCURACY:

Zero error: ±0.1% FS (max), Scale error: ±0.2% (max)

OPERATING ENVIRONMENT:

-40° to +70° non-condensing

Specifications are subject to change without notice.