- Home

- Companies

- MKR Metzger GmbH

- Products

- MKR - Model TB 250 - Tramp Oil ...

MKR - Model TB 250 -Tramp Oil Separator

Specific Characteristics: Throughput 200 - 400 l/h, Pre Filter 350 µm, Stainless Steel Angle Section, Self-priming Pump (compressed-air membrane pump), Working without Electrical Connection.

- Extending the useful life (evaluated by appearance) of the emulsion and improvement of the odor

- Bypass cleaning without stopping the machines

- Lowering the costs of waste disposal

- Short amortization period

- Adjustable flow rate

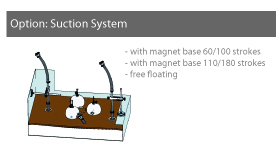

Options

- Suction System with magnet base 60/100 strokes

- Suction System with magnet base 110/180 strakes

- Suction System Free Floating

Housing

Welded construction of 3 mm stained VA-sheet

Hoses

Suction hose: length 3 m, Ø 20 mm

Quick connector at the hose end

Return hose for cleaned medium,

Length 3 m, Ø 32 mm, Type Amorvin - HNA

Tramp oil separition

By coalescence separator

Pre filter, for pump protection

Single filter spezial steel insert 350 μm

Pump

Compressed-air membrane pump 250l/h, 3 bar

Gravity feedback of cleaned medium

Max. feedback height 650 mm

Documentation

Operating manual

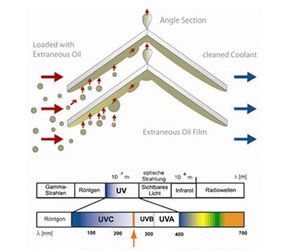

We apply the coalescence principle to separate out extraneous oils. In the process, the rising light oil fraction of extraneous oils is skimmed from the surface using a floater. This fraction is then carefully transferred to an interim processing container. A special coalescence packet recovers dispersed oil droplets from the emulsion and returns them as clean and effective coolant back to your machine.

Functional principle of the coalescence separator

Tiny oil droplets are adsorbed on the surfaces of blade fins and coalesce to larger drops. The oil then rises up through special drill holes. This process allows the removal of even very finely dispersed droplets.

Functional principle of the UVC steriliser

UVC254nm: The special 254-nm UVC irradiation effectively controls the germ count.