- Home

- Companies

- Tri-Mer Air Pollution Control Systems

- Products

- Tri-Mer - Model CCS - Cloud Chamber Gas ...

Tri-Mer - Model CCS -Cloud Chamber Gas / Particulate Scrubber

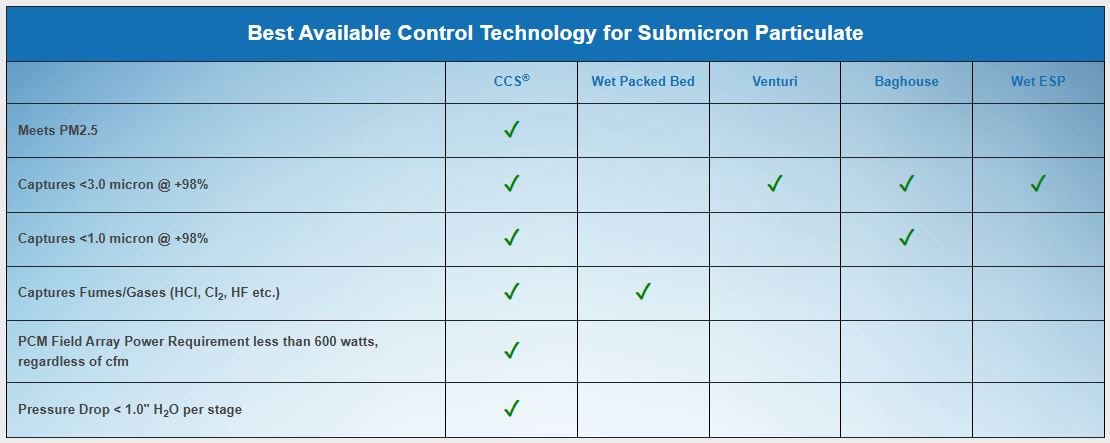

Tri-Mer’s Cloud Chamber scrubber uses charged water droplets to remove particulate (PM2.5, fine, submicron ultrafine and condensable as well as PM10 and coarser particles) at efficiencies of 99% or higher. Simultaneously, CCS removes all gases that are treatable with a wet scrubber, including HCl, NO2, SO2, Cl2, NH3, HF, H2SO4, HNO3, ammonia and amine compounds. The ability to treat particulate and corrosive fumes simultaneously and efficiently is a prime advantage of CCS technology.

- Accomodates: high loadings

- Not sensitive: to load flux

- Low: operating cost

- Eligible for Routine: System Performance Review

Cloud Chamber Scrubber works by passing an incoming gas stream through a scrubbing cloud of dense, charged water droplets. Inside the wet scrubber, billions of charged droplets interact with the particles. When a particle and droplet pass within 20 microns, the droplet charge induces a dipole force which causes the particle to be pulled into the droplet, making each water droplet a particle collector.

Droplets collect particles as they interact with the gas stream, and are washed into the sump. Captured particles agglomerate, settle, and are removed as a low volume slurry. Clean water from the top of the sump is re-circulated to the preconditioning chamber (PCC), where it is recharged, completing the cycle.

The Cloud Chamber Scrubber has three zones: preconditioning chamber (A) for removal of coarse particles and humidity-temperature adjustment; cloud generation vessel (B) for removal of neutral and negative submicron particles, and a second cloud generation vessel (C) with negatively charged droplets to capture neutral and positive particles. Treated air flows through a mist eliminator prior to discharge.

Just 10 watts per 1000 cfm are required to charge the water droplets, plus moderate pump power for recirculation. Maintenance costs are also low: Cloud Chamber uses minimal water, and generates less than 1.5” w.g. pressure drop across the system.

Cloud Chamber gas / particulate scrubber accommodates loadings as high as 2,000 mg/m3, reducing mass emissions to below 5 mg/m3. Its performance is superior to high-energy venturis, diffusion candles and ESPs. It is a practical engineering solution as a stand-alone unit, or as a tail gas scrubber for existing equipment.

- Diesel from ships at port

- Diesel engine test cells

- Diesel locomotive engines

- Large stationary diesel equipment

- Refineries

- Glass furnace emissions

- Solar panel manufacturing

- Abrasives production

- Chemical manufacturing

- Plastics manufacturing

- Biofuels production

- Sulfuric and nitric acid production

- Wet electrostatic precipitator replacement