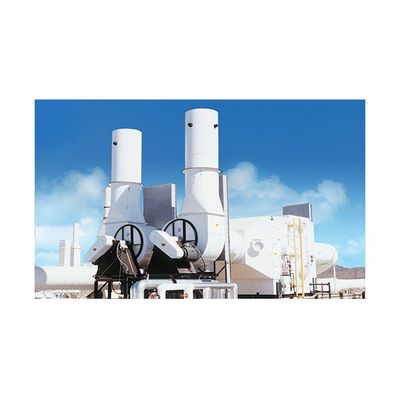

Tri-Mer Air Pollution Control Systems products

Wet Scrubbers

Tri-Mer - Wet Scrubbers for Air Pollution Control

A Wet Scrubber is an air pollution control device which uses a liquid to remove contaminants from a gas stream.

The removal process is achieved by bringing the gas stream into contact with the scrubbing liquid, which facilitates mass transfer of the contaminants into the liquid. When the water is recirculated, addition of fresh water is necessary to purge contaminants and replace evaporation losses. Fresh water may be added to the recycle continuously or periodically. Tri-Mer has a variety of high-efficiency wet scrubbers for the removal of inorganic gases, odors, fumes, acid fumes, sulfuric acid, chrome, NOx, fine particulate, aerosols, mercury, HCl, Cl2, SO2, and HF.

Tri-Mer - Mercury Scrubber

Tri-Mer Mercury Scrubber provides up to 99.9% reduction in Hg vapor emissions. It is ideally suited to lower emissions from coal-fired power plants, municipal waste incinerators, cement kilns, chlor-alkali plants and gold mining, the major contributors to mercury pollution in the U.S.

Tri-Mer - Cloud Chamber Gas / Particulate Scrubber

Tri-Mer’s Cloud Chamber scrubber uses charged water droplets to remove particulate (PM2.5, fine, submicron ultrafine and condensable as well as PM10 and coarser particles) at efficiencies of 99% or higher. Simultaneously, CCS removes all gases that are treatable with a wet scrubber, including HCl, NO2, SO2, Cl2, NH3, HF, H2SO4, HNO3, ammonia and amine compounds. The ability to treat particulate and corrosive fumes simultaneously and efficiently is a prime advantage of CCS technology.

Tri-Mer - Industrial Odor Scrubbers

Tri-Mer systems are ideal for continuous performance applications. Applications include chemical plants, petrochemical facilities, municipal waste treatment, asphalt manufacturing, foundries and food processing.

Tri-Mer - Incinerator Scrubber

Q-Scrub Incinerator Scrubber delivers scrubber efficiencies of 95-99.99%. Systems can be engineered to guarantee any outlet rating. Most stack gas emissions requirements are based on a mass emissions standard of lbs./hr. in vs. lbs./hr. out for contaminants such as HCl, Cl2, SO2, HF, etc.

Tri-Mer - Venturi Scrubber

The high-pressure venturi scrubber is a well-known method for removing aerosols and fine dusts from industrial gas streams, particularly those with high humidity levels. Tri-Mer’s fixed throat venturi scrubber produces optimum acceleration of the gas, and shearing of the droplets. The resultant, larger “particle” is then removed from the gas stream and impinged on a separator downstream.

Tri-Mer UltraScrub - Acid Fume Scrubber

UltraScrub is Tri-Mer’s trade name for its cartridge-based acid fume scrubber.

Tri-Mer - Chrome Scrubber

Tri-Mer’s C/E-1 Chrome Scrubber scrubs all chrome, including Cr6 and Cr3, at efficiencies of 99.5% or higher, regardless of input loading. Our chrome scrubber features a multi-layer polypropylene pad system which operates under negative pressure. The filter apparatus is washed continuously in a nearly closed loop configuration. When chrome levels approach set point (generally 3000 ppm) water is forwarded to chrome recovery, or returned to the plating bath.

Tri-Mer - NOx Multi-Chem Wet Scrubber System

Tri-NOx scrubber systems accommodate any combination of NO and NO2, including nitration-related NOx, which is typically high on the NO2 scale, and combustion-related NOx, which is higher in NO. Tri-Mer’s NOx scrubber guarantees a clear stack, eliminating the plume generated by high NO2 loading. This yellow-brown emission is generated by processes using nitric acid.

Tri-Mer - Fume and Mist Eliminator System

Included are H2SO4, heavy metals, VOCs and other fumes generated from steel pickling, plating, anodizing and other common industrial processes. Fumes from battery charging can be eliminated more efficiently, and with less water and energy using Tri-Mer's Fan/Separator - a huge benefit for this important growth market. Fan/Separator scrubber sections and fans are manufactured in tandem to prevent fan under-sizing, an issue that is often under-appreciated until it affects performance. Fan outlet velocity is precisely controlled, so air crossing the rigid packed media stays comfortably within design parameters. The system is positively pressured, working the reverse of conventional "negative air" scrubbers. Thus, air is pushed, rather than pulled, through the system.