- Home

- Companies

- Disab Vacuum Technology

- Products

- Disab Vacturion - Model DL14 - Truck ...

Disab Vacturion - Model DL14 -Truck Mounted Vacloader

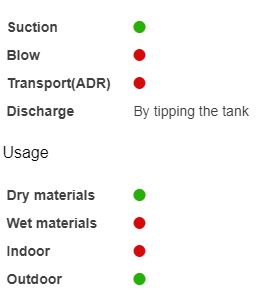

This vacloader is driven by the truck’s engine and has a suction only feature. It has limited add-ons available. Its square tank design makes it suitable for dry applications and it’s often used in following industries: cement, steel, building, energy etc.

The DL14, with its 220 kW suction power meets the industry’s high demands on efficiency, reliability, ease of use and maintenance.

The Vacturion DL14 is an optimum tool to handle all types of material. The square box design is most suitable for dry material. It is designed to operate as a stand-alone vacuum loader for work with 6” hoses but can equally well operate as a central vacuum unit connected to a fixed tube system, facilitating multiinlet cleaning. Truck engine power supply optimizes load capacity as well as economy of operation. The unit features

- Sturdy design

- Efficient high vacuum pump (>90% vacuum)

- Filter system with air chock filter cleaning

- 220 kW, 8100 m³/h suction capacity

- On board storage of hoses, pipes and tools

- Hydraulically operated tailgate, tailgate lock and tipping

The unit is designed for the industrial environment and is easy to use for the operator. Safety at work and low maintenance cost are features included in our philosophy.

The truck, if supplied by customer must have the approval of the DISAB Technical Department. A day cab solution together with the short wheelbase of 4600 mm add to a compact unit easy to manoeuvre. A 9 tonne front axle and 19 tonne boggie paired with the DISAB design provide optimised loading capacity.

The suction unit is powered via a well reputed power transmission. Suction power is regulated on the unit controls by adjusting the RPM of the truck.

The material is sucked via 6” hoses through an 8” cyclone inlet. (Or hose boom, option). Sucked material is separated from the air stream in several steps. First in the cyclone, secondly through “fall chamber” principle in the container, thirdly in the filter compartment and finally in the safety filters.

The filling of our 10 m³ container can continue until stopped by an automatic level guard. The fine dust, collected by the filters, is kept in a separate compartment.

Unloading is done by hydraulic tipping, supported by vibrators (optional). While tipping, the filter chamber can be emptied through pneumatic opening of the filter hatch.

Literally anything, fitting into the 6” hose, can be sucked and transported into the container. Volumes sucked vary with material, distance to vacuum unit and opera-tor. As guidance, 10 m³ of cement at a 20 meter distance would be collected within 20-25 minutes. Within reason, the capacity is independent of height differences. Our units are used by manufacturers of cement, lime, chemicals, plastics etc. Foundries, steel mills, quarries, pulp and paper, incineration plants, shipyards and power plants are other examples of users.

- Vacuum pump: 3-lobe roots pump

- Max vacuum, mbar: 950

- Max overpressure, mbar: N/A

- Air volume m3/h (unloaded): 8100

- Operation speed (rpm): 2650

- Power: 220

- Voltage Frequency, V/Hz: N/A

- Tank volume (m3)*: 8/10/12

- Total tank volume: 11/13/15m3

- Power source: Truck powered

- Engine type: N/A

- Tank material: Carbon steel

- Tank tipping: Hydraulic front cylinder, double acting system. Tailgate is hydraulically operated and locked.

- Main filter system (m2): 70 stainless steel cages with filter socks in needled polyester glazed surface. Filter area is 26 m2

- Safety filter surface(m2): 34

- Cooling air: Cartridge filter

- Atex: N/A

- Weight and Dimensions**

- Complete unit (including chassis): 19 300kg

- Total unit length including tuck chassis: 8 300mm

- Total width: 2 500mm

- Height (incl. hose boom): 4 000mm