- Home

- Companies

- Disab Vacuum Technology

- Products

- Disab Centurion - Model P10 - Truck ...

Disab Centurion - Model P10 -Truck Mounted Vacloaders

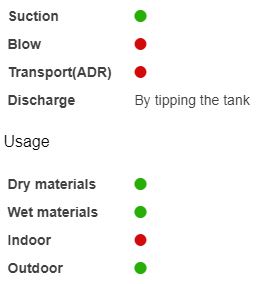

This vacloader is driven by the truck’s engine and has a suction only feature. It has great flexibility for different applications with multiple add-ons available. Its round tank design makes it suitable for wet and dry applications and it’s often used in following industries: cement, steel, paper & pulp, energy etc.

A truck mounted vacloader offering three levels of capacities in its air transport of bulk materials, 6000 m³/h, 8000 m³/h or 10000 m³/h.

The unit is driven by the truck’s engine and this gives a compact high capacity machinery with 9 ton load capacity (chassis and option dependant).

The material tank and filter compartment are combined and the dust from the filter compartment is emptied through a hatch in the partition wall in the tank at the same time as the tank is tilted up.

Collected material is discharged by tipping the tank.

- Vacuum pump: 3-lobe roots pump

- Max vacuum, mbar: 950

- Max overpressure, mbar: N/A

- Air volume m3/h (unloaded): 8100

- Operation speed (rpm): 2650

- Power: 220

- Voltage Frequency, V/Hz: N/A

- Tank volume (m3)*: 10/12/14

- Total tank volume: 12,7/14,7/16,7m3

- Power source: Truck powered

- Engine type: N/A

- Tank material: Carbon steel/stainless steel

- Tank tipping: Hydraulic front cylinder, double acting system. Tailgate is hydraulically operated and locked.

- Main filter system (m2): 70 stainless steel cages with filter socks in needled polyester glazed surface. Filter area is 26 m2

- Safety filter surface(m2): 34

- Cooling air: Cartridge filter

- Atex: On request

- Weight and Dimensions**

- Complete unit (including chassis): 19 500kg

- Total unit length including tuck chassis: 9 400mm

- Total width: 2 500mm

- Height (incl. hose boom): 3 900mm