- Home

- Companies

- RETSCH - part of Verder Scientific

- Products

- Retsch - Model ZM 300 - Ultra ...

Retsch - Model ZM 300 -Ultra Centrifugal Mills

Rotor mills are used for high-speed size reduction of soft to medium-hard as well as temperature-sensitive or fibrous materials. The powerful Ultra Centrifugal Mill ZM 300 provides maximum grinding performance combined with ease of use. The variable speed from 6,000 to 23,000 rpm allows for gentle, neutral-to-analysis sample preparation in a very short time.

- Feed material: soft, medium-hard, brittle, fibrous

- Material feed size*: < 10 mm

- Final fineness*: < 40 µm

- Gentle high-speed pulverization due to pre- and fine grinding in one working run

- Optimum process control and reproducibility based on monitoring of the cassette temperature

- Patented cassette system for maximum sample recovery and easy cleaning

- Optional cassette for sample volumes up to 600 ml

- Wide speed range from 6,000 to 23,000 rpm

- Defined final fineness due to ring sieves with aperture sizes from 0.08 – 10 mm

- Collecting vessels for sample volumes from 250 ml to 4.5 l

- Automated vibratory feeder and various cyclone systems available

The speed range from 6000 to 23000 rpm allows for optimum adaptation of the grinding process to the sample requirements by keeping the grinding time as short as possible and the temperature increase as moderate as possible. Too much heat may have a negative effect on the grinding results, for example, if moisture or volatile components escape.

The ZM 300 is equipped with an integrated temperature sensor which measures the temperature of the cassette lid near the ring sieve. The measured temperature is constantly shown in the mill’s display, allowing the user to optimize the grinding process and improve reproducibility.

Application examples

Grind sizes of plastic materials (POM or PP) after grinding with different sieves and speeds. The speed of 23,000 rpm results in a higher fineness for all sieves compared to grinding at 18,000 rpm. For example, a 19 % reduction in fineness can be achieved when POM is ground with a 0.12 mm distance sieve at 23,000 rpm.

The maximum sample throughput, e.g. when crushing chicken feed with a 0.5 mm ring sieve, could be increased by 16% when crushing at maximum speed of 23,000 min-1 instead of 18,000 min-1.

Cryogenic or cold grinding is the ideal solution for pulverizing samples that cannot be reduced to the required fineness at room temperature. This procedure involves the use of grinding aids such as liquid nitrogen (-196 °C, embrittlement of the sample outside the mill) or dry ice (-78 °C, sample/dry ice mixture) to embrittle the sample material by cooling, and thus improve the breaking behavior.

In addition, highly volatile components are better preserved in the sample by cooling. Cryogenic grinding is easy to perform with the ZM 300 and is recommended especially for plastics or very temperature-sensitive samples. The video shows the process with the predecessor model ZM 200, which is identical in the ZM 300.

In combination with the cyclone suction unit, the Ultra Centrifugal Mill ZM 300 mill is even suitable for grinding light and heat-sensitive materials.

- Efficient cooling of sample and grinding tools

- Improved sample discharge from the grinding chamber

- Particularly suitable for large volumes

- The cyclone accommodates sample bottles of 0.25, 3 and 5 liters

- Ideal for cryogenic grinding

The wide range of accessories makes the ZM 300 extremely versatile. The desired final fineness can be determined by selecting the ring sieve. Rule of thumb: After grinding, approximately 80% of the sample material is about half the size of the sieve aperture. You can choose between sieves with apertures ranging from 0.08 to 10 mm.

For the ZM 300 ring sieves with reinforced rim are used which are equipped with four grooves for secure locking. Distance sieves, also secured and fixed by four grooves, have a gap between the sieve mesh and the rotor, which reduces shearing effects and thereby heat generation.

Rotors are available with either 6, 12 or 24 teeth. The standard rotor with 12 teeth is suitable for almost any material and requirement. For fibrous samples, such as straw, the rotor with 6 teeth is typically used, while for fine samples the rotor with 24 teeth is best suited.

For neutral-to-analysis work, or for pulverizing abrasive samples, grinding tools in various materials are available: titanium (titanium-niobium coating), steel 1.4404, tungsten carbide coating.

In the standard collecting vessel with 900 ml nominal volume, up to 300 ml of sample can be ground in one working step. With the large-volume cassette, the useful volume can be doubled to 600 ml. When utilizing a cassette with cyclone, various collecting vessels up to 4,500 ml useful volume are available.

The Vibratory Feeder DR 100 is controlled via an interface and conveys material in a load-dependent manner to the hopper of the ZM 300. This procedure ensures uniform grinding with maximum sample feed. The use of a feeder is particularly advantageous for large sample quantities.

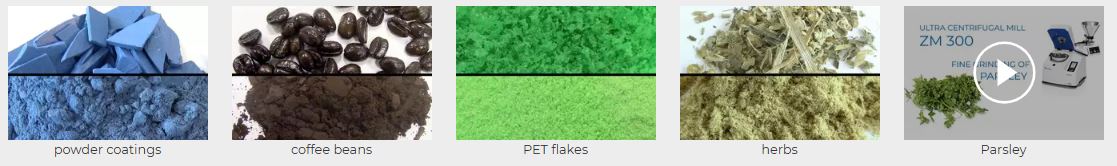

The ZM 300 is suitable for grinding a wide variety of materials:

waste, graphite, collagen, drugs, fertilizers, feed pellets, grains, spices, rubber, wood, coffee beans, bones, coal, food, corn, minerals, paper, plant parts, polymers, powder coatings, rice, seeds, straw, sweets, tobacco, textiles, chemical products, electronic components, dried fruits and vegetables, dried larvae, pharmaceutical products.

The grinding process is carried out by impact and shearing forces between the rotor and the fixed ring sieve. The sample material is fed into the rotor via a funnel with splash protection, accelerated outwards by centrifugal force, and pre-ground by the wedge-shaped rotor teeth. The subsequent fine grinding takes place in the narrow gap between the rotor and the sieve.

Thanks to this two-stage process, sample preparation is particularly gentle and fast. Since the ground material only remains in the grinding chamber for a short time, the characteristic properties of the sample are retained. The end product is collected in the collection vessel, cyclone, or paper filter bag that surrounds the grinding chamber.

- Applications: fine grinding

- Field of application: agriculture, biology, chemistry / plastics, construction materials, engineering / electronics, environment / recycling, food, geology / metallurgy, medicine / pharmaceuticals

- Feed material: soft, medium-hard, brittle, fibrous

- Size reduction principle: impact, shearing

- Material feed size*: < 10 mm

- Final fineness*: < 40 µm

- Batch size / feed quantity*: 300 ml with standard cassette

- 600 ml with volume cassette

- 4500 ml / 2500 ml / 450 ml / 230 ml with cyclone

- Speed at 50 Hz (60 Hz): 6,000 - 23,000 min-1, free selectable

- Rotor peripheral speed: 31 - 119 m/s

- Rotor diameter: 99 mm

- Types of rotors: 6-tooth rotor / 12-tooth rotor / 24-tooth rotor

- Material of grinding tools: stainless steel, titanium, stainless steel with wear-resistant coating

- Sieve sizes: trapezoid holes 0.08 / 0.12 / 0.20 / 0.25 / 0.50 / 0.75 / 1.00 / 1.50 / 2.00 mm

- round holes 3.00 / 4.00 / 5.00 / 6.00 / 10.00 mm

- Setting of grinding time: no

- Collector capacity: 900 ml with standard cassette

- 1200 ml with volume cassette

- 5000 ml / 3000 ml / 500 ml / 250 ml with cyclone

- Drive: 3-phase asynchronous motor with frequency converter

- Power connection: 1-phase

- Protection code: IP 30

- Power consumption: 1750 VA ((200..240V), 1400 VA (110..120V)

- W x H x D closed: 452 x 431 x 426 mm

- Net weight: ~ 38 kg

- Standards: CE

*depending on feed material and instrument configuration/settings