- Home

- Companies

- Senix – a division of BinMaster Sensors ...

- Products

- Senix ToughSonic - Model 200.14 - ...

Senix ToughSonic - Model 200.14 -Ultrasonic Level Sensor for Liquid Measurement

Product code: TS-200.14. Minimum Purchase: 1 unit. Max Measuring Distance: 14 ft (4.3 m). Optimum Measuring Distance: 10 ft (3 m). Deadband: < 3.5" (89 mm). Temperature Range: -40° to 158° F (-40° to 70° C). Protection: NEMA 4X, IP 68, NEMA 6P. Area Classification: Ordinary Locations. Cable Length: 6.5 feet. Mount: 1" NPT Thread Upper, 1.5" NPT Thread Lower. Dimensions (L x Dia): 4.99 in (126 mm) x 3.04 in (77 mm). Housing: PVDF. Legacy Part Number: LVL-140-485, LVL-140-232. Output: RS-485 or RS-232.

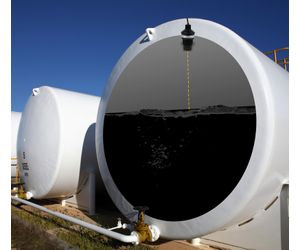

ToughSonic® TS-200 ultrasonic level sensors deliver non-contact, highly accurate liquid level measurement in chemical tanks, diesel fuel storage, and industrial liquid applications. Designed for durability, these compact and rugged sensors withstand exposure to harsh chemicals, acids, and bases. They are ideal for demanding paper processing, food production, and industrial storage applications.

- Chemical-Resistant PVDF Housing: Ensures long-term performance in corrosive environments.

- Non-Contact Ultrasonic Technology: Accurate level measurement without sensor contact with the liquid.

- Wide Application Use: Suitable for closed or open tanks, chemical processing, and diesel fuel storage.

- Extreme Durability: Rated IP68, NEMA-4X, and NEMA-6P for reliable indoor and outdoor use.

- Advanced Configuration: Easily adjustable with SensorView™ software for setup, testing, and cloning sensors.

- Short Nose & Deadband: Measures closer to the full tank for improved accuracy.

- Versatile Mounting Options: Features 1.5-inch and 2.0-inch BSP bottom threads and 1.0-inch NPT top threads.

- Flexible Installation Options: Top and bottom mounting threads

- Ingress Protection: IP68 (submersible), NEMA-4X, NEMA-6P

- Output Options: Five outputs plus serial data

- Temperature Compensation: Ensures accuracy in varying conditions

- PC Configurable: Adjust sensor settings easily

- Chemical Tank Level Monitoring: Safe for use in chemical environments compatible with PVDF.

- Aggressive Materials & Fuel Storage Tanks: Reliable level measurement in hostile applications.

- Industrial & Factory Environments: Designed for use in the harshest conditions.

- Agriculture: Liquid level monitoring in irrigation systems, ag chemicals, livestock monitoring.

- Open-Air Liquid Level Monitoring: Measures tank levels up to 14, 20, or 35 feet.

- Maximum Range: 14 feet (4.3 meters)

- Optimum Range: 4 in. to 10 ft (100 mm to 3 meters)

- Deadband: 0-12 in (0-30.5cm)

- Temperature: -40° to 158°F (-40° to 70°C)

- Humidity: 0 to 100% operating

- Protection: NEMA-4X, NEMA 6P, IP68

- Transducer: Chemically isolated piezoelectric

- Compensation: Temperature compensated (selectable in SensorView™)

- Resolution:

- Serial data: 0.0034 in. (0.086 mm)

- Analog steps: 4099 (0-10 VDC),

- 3279 (4-20 mA)

- Repeatability:

- Nominal 0.2% of range @ constant temp.

- Affected by target, distance, environment

- Update Rate: 20 Hz (50 ms), SensorView adjustable; affected by SensorView filter selections

Outputs

- Voltage Output:

- 0-10, 0-5 VDC or SensorView customized

- 10 mA maximum output current

- Current Loops (x2):

- Two 4-20 mA current loops:

- Current sourcing and current sinking

- Max loop resistance 450 ohms each

- SensorView customized

- Both share calibration parameters

- Switches (x2):

- Two switches, SensorView customized

- 150 mA max @ 40 VDC max

- SensorView selected as sinking (NPN) or sourcing (PNP)

- Adjustable setpoint, polarity, hysteresis, ON and OFF timing

- Serial Data Interface:

- Modbus & streaming protocols

- 9600-115200 baud (configurable)

- 8 data bits, 1 stop, no parity

- RS-485 permits multi-sensor networks

- Part number determines interface

Mechanical

- Housing:

- Injection moulded, chemically resistant

- Polyvinylidene fluoride (PVDF)

- Also known as Kynar, a registered tradename of Arkema Inc.

- Mounting

- Top mount: 1-inch NPT

- Bottom: 1-1/2 in. NPT

- Cable:

- Potted into sensor, pigtail termination

- 6.5 feet (2 meters), PUR jacketed

- Custom lengths available

- Standard models: 9-wire shielded + drain

- Serial data-only models: 4-wire + drain

- Total Weight:

- 21.2 oz. (0.60 kg)

- Weight includes 6.5 ft (2 meter) cable

*Specifications are subject to change without notice.

Acids, bases and chemical tanks of all kinds meet their match versus the ToughSonic®-200 series. The same rugged, compact design of ToughSonic’s ultrasonic sensors encases heavy-duty electronics in a dutiful polyvinylidene fluoride (Kynar®) housing.

Used to measure a wide variety of liquids: diesel fuel in rail locomotives, chemical tanks in the paper and food processing industries, and benign liquid level applications.

ToughSonic chemical sensors are also frequently utilized for distance ranging, flood monitoring, object detection, roll diameter and general industrial automation in hazardous environments.

Need Tough? Choose a ToughSonic chemical level sensor.

All chemical sensors include serial data communications to connect with SensorView™ software or your equipment.

RS-232 or RS-485 Format

- Selectable Modbus (Default) or ASCII streaming protocols

- Baud rates from 9600 (Default) to 115200 bits per second (bps)

- Many other features adjustable using SensorView

- RS-485 Serial Data Interface

Multi-drop Modbus addressing permits networks of up to 32 sensors

- Better noise immunity in industrial environments

- Allows longer cable lengths at higher baud rates

Multiple Outputs for Peak Connectivity

- Analog 0-10 VDC is typically used with motor drives and similar equipment

- Switches configurable as Sinking (NPN) or Sourcing (PNP)

- TWO analog 4-20 mA current loops (sourcing and sinking) for process industry transmitter applications

LAN or Cloud Connection

Compatible with BinCloud® Software

- Send data from miles away, within plant or outdoors

- Energy efficient gateway operates on 120–240 VAC

- For tank levels or outdoor bodies of water

- Get alerts & notifications for high- & low-level conditions

- Historical level and usage reports for an optimized supply chain

Industry 5.0 has arrived with SensorView™ sensor configuration software.

SensorView is included at no charge. It runs on Windows PC and connects to sensors via a serial data port.

Our setup kits provide everything you’ll need to connect through a USB port, including a power supply, sensor-PC interface, and cables.

Over 80 Parameters to Customize

- Analogs: Slope, distance endpoints, analog value limits

- Switches: Set points, window features, time delays

- All Outputs: Power on, loss of echo, loss of sync responses

- Serial Data: Communications, SYNC modes and functions

- Measurements: Temperature compensation, sensitivity, data filters, measure rate, gain settings and data processing filters

- Adjustments: Stored in-sensor memory, accessible even when power is off